Measuring device for simultaneously determining a rotation angle and a displacement position

A technology of measuring device and moving position, applied in the direction of measuring device, electromagnetic measuring device, electric device, etc., can solve the problems of labor-intensive optical sensor, expensive grating-cylinder processing, etc., and achieve the effect of high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

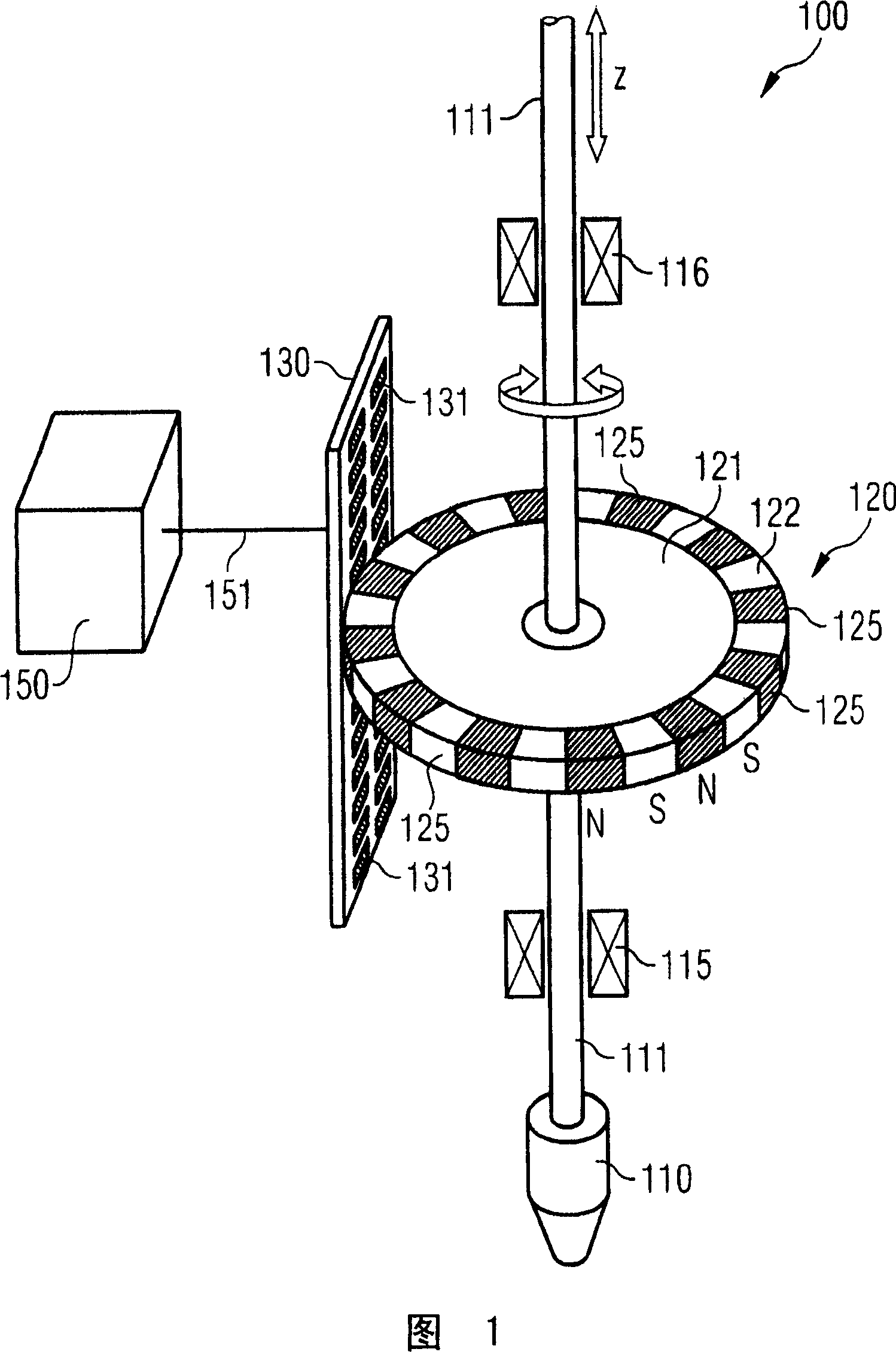

[0032] FIG. 1 shows a measuring device 100 for simultaneously obtaining the angle of rotation and the displacement position of a suction tube 110 as a fixture of a component for carrying out an assembly process. The suction tube 110 rests on a hollow rod 111 , which is a shaft supported by two bearing parts 115 and 116 . The bearing is configured such that the hollow rod 111 is rotatable about its longitudinal axis and also axially displaceable along its longitudinal axis parallel to the z-direction. In a manner not shown, this shaft is coupled not only to a linear drive for axially displacing the hollow rod 111 but also to a rotary drive for rotating the hollow rod 111 about its longitudinal axis. This hollow rod 111 serves to transmit negative pressure to the suction tube 110 from a vacuum generating device not shown, so that elements can be held pneumatically by the suction tube 110 when a corresponding negative pressure is applied.

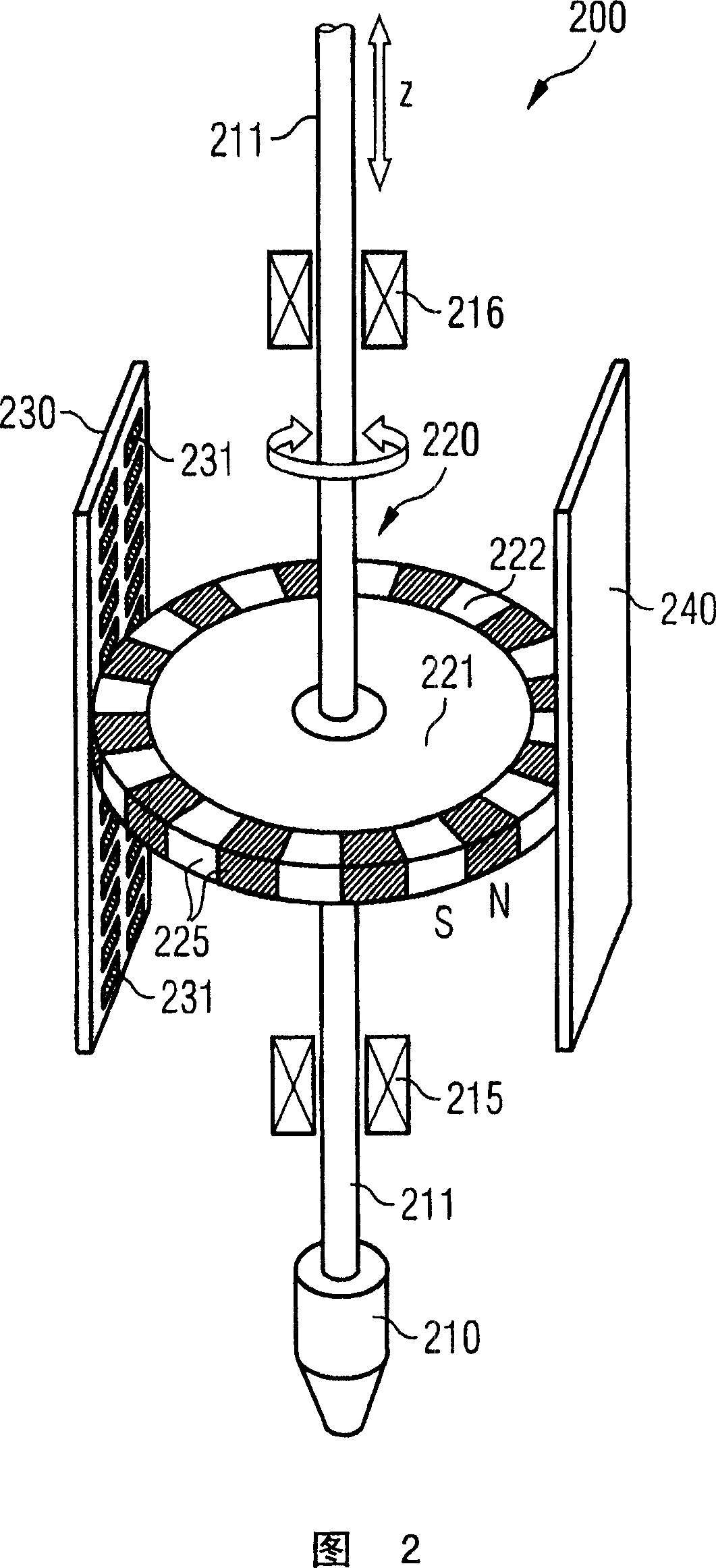

[0033] The measuring device 100 also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com