Method and system for detecting corrugation defect and manufacturing method of photomask

A technology of defect inspection and photomask, which is applied in the photolithographic process of patterned surface, optical testing for flaws/defects, and originals for photomechanical processing, etc. It can solve the problems of inability to detect ripple defects and changes with high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, preferred modes for implementing the present invention will be described with reference to the drawings.

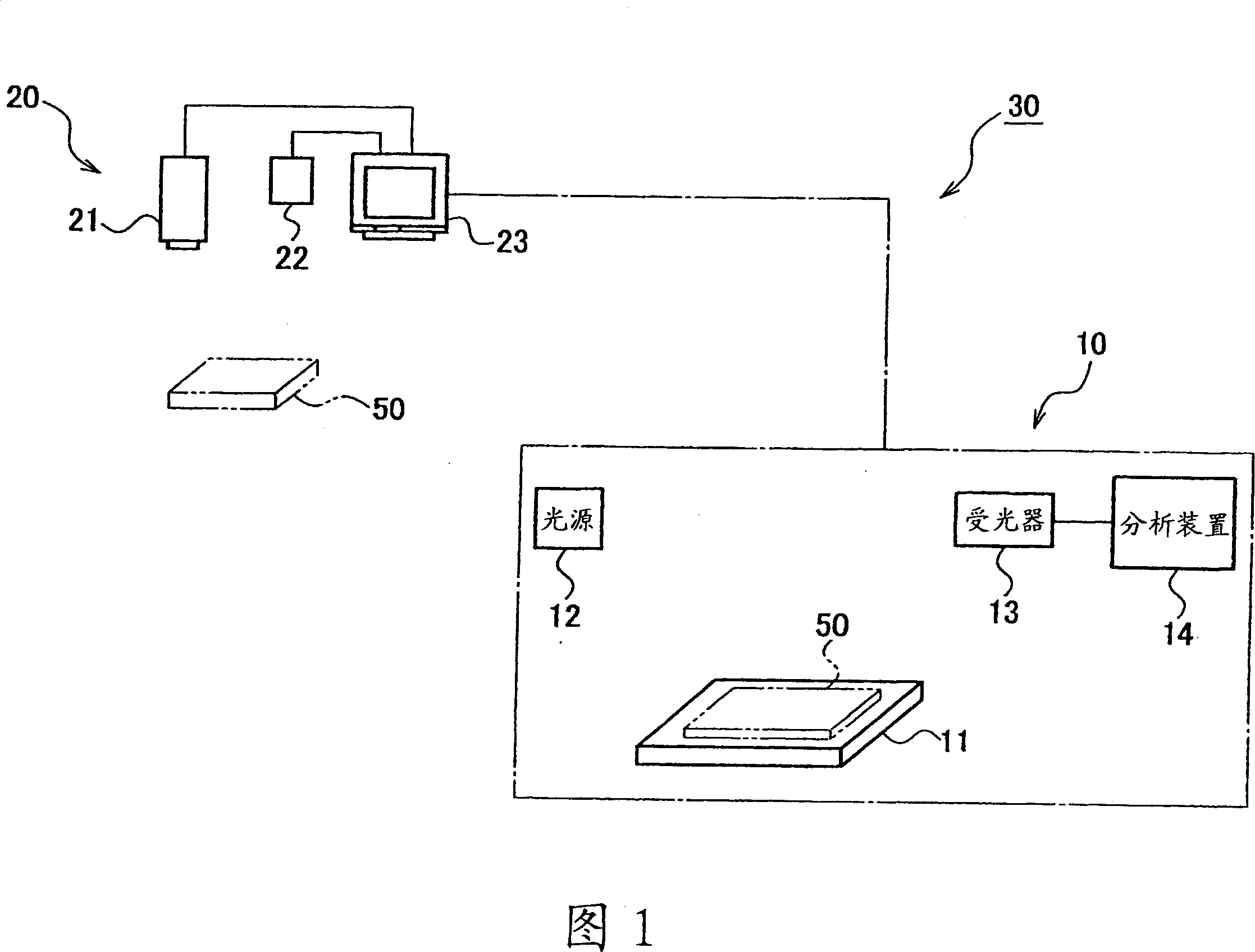

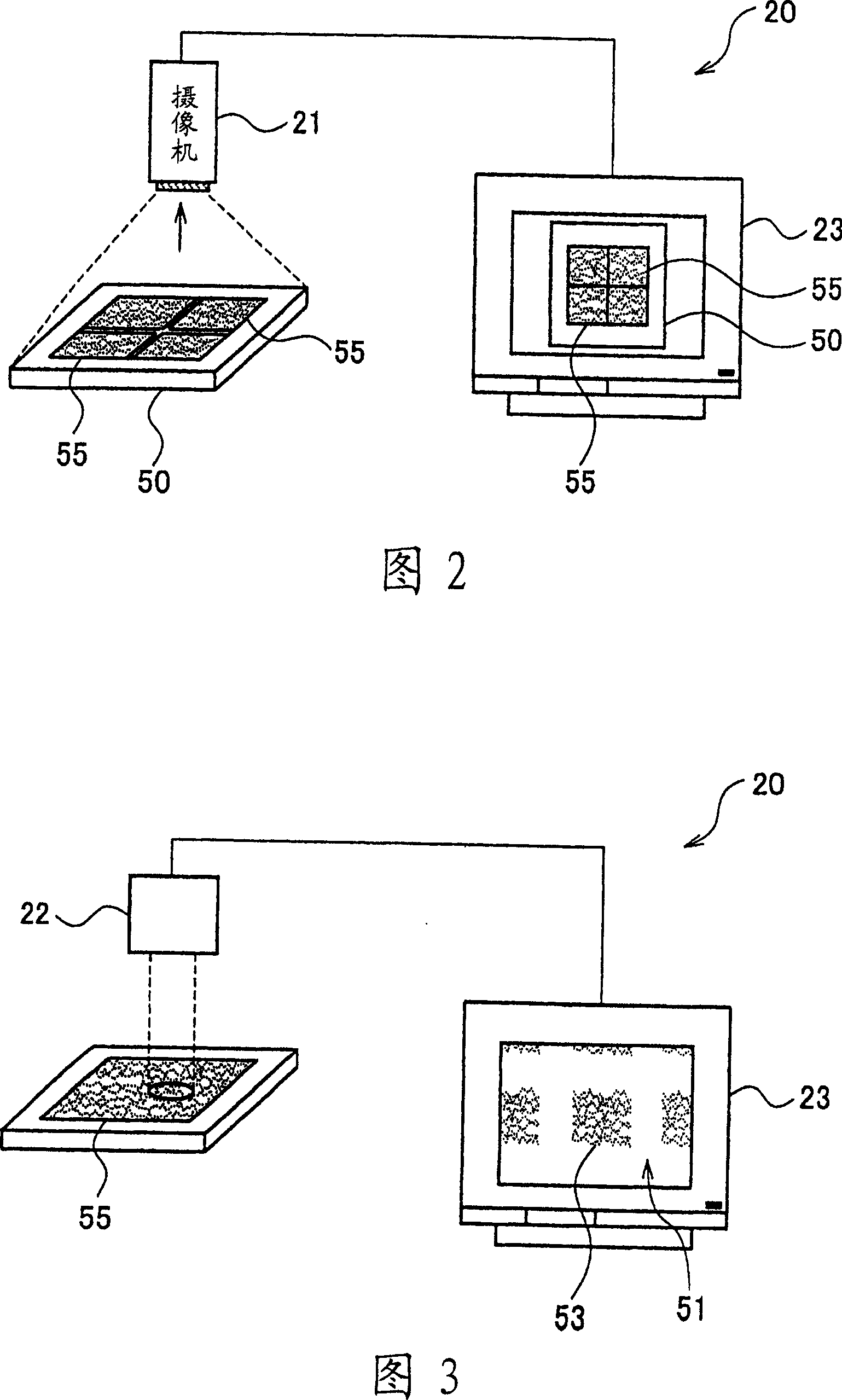

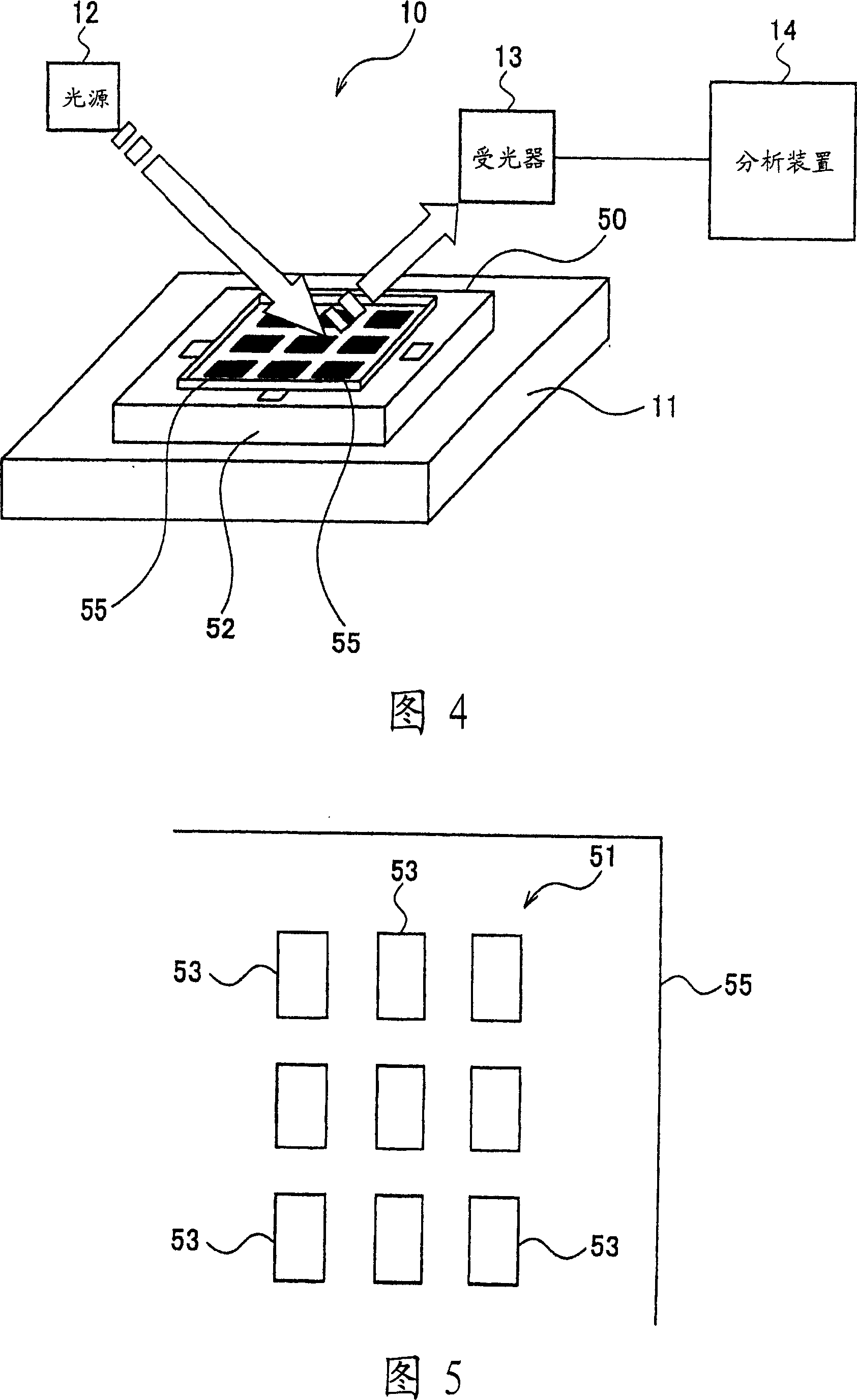

[0025] FIG. 1 is a system configuration diagram showing an embodiment of a mura defect inspection system of the present invention. FIG. 4 is a perspective view showing a state of inspecting a mura defect by the mura defect inspection apparatus in FIG. 1 .

[0026] The moire defect inspection system 30 shown in FIG. 1 is a system for detecting a moire defect generated in a repeated pattern 51 ( FIG. 5 ) formed on the surface of a photomask 50 as an object to be inspected, and is configured to have a pattern information acquisition unit as a pattern information acquisition unit. The pattern information acquisition device 20 of the above-mentioned, and the moire defect inspection device 10 as the moire defect inspection unit. The photomask 50 described above is an exposure mask used for manufacturing a video device.

[0027] Here, the video device is, for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com