Optical fiber and its preform as well as method and apparatus for fabricating them

An optical fiber preform and preform technology, applied in the field of optical fibers, can solve the problems of disturbing the periodic structure, leaving gaps and openings, etc., to achieve the effect of avoiding labor intensity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

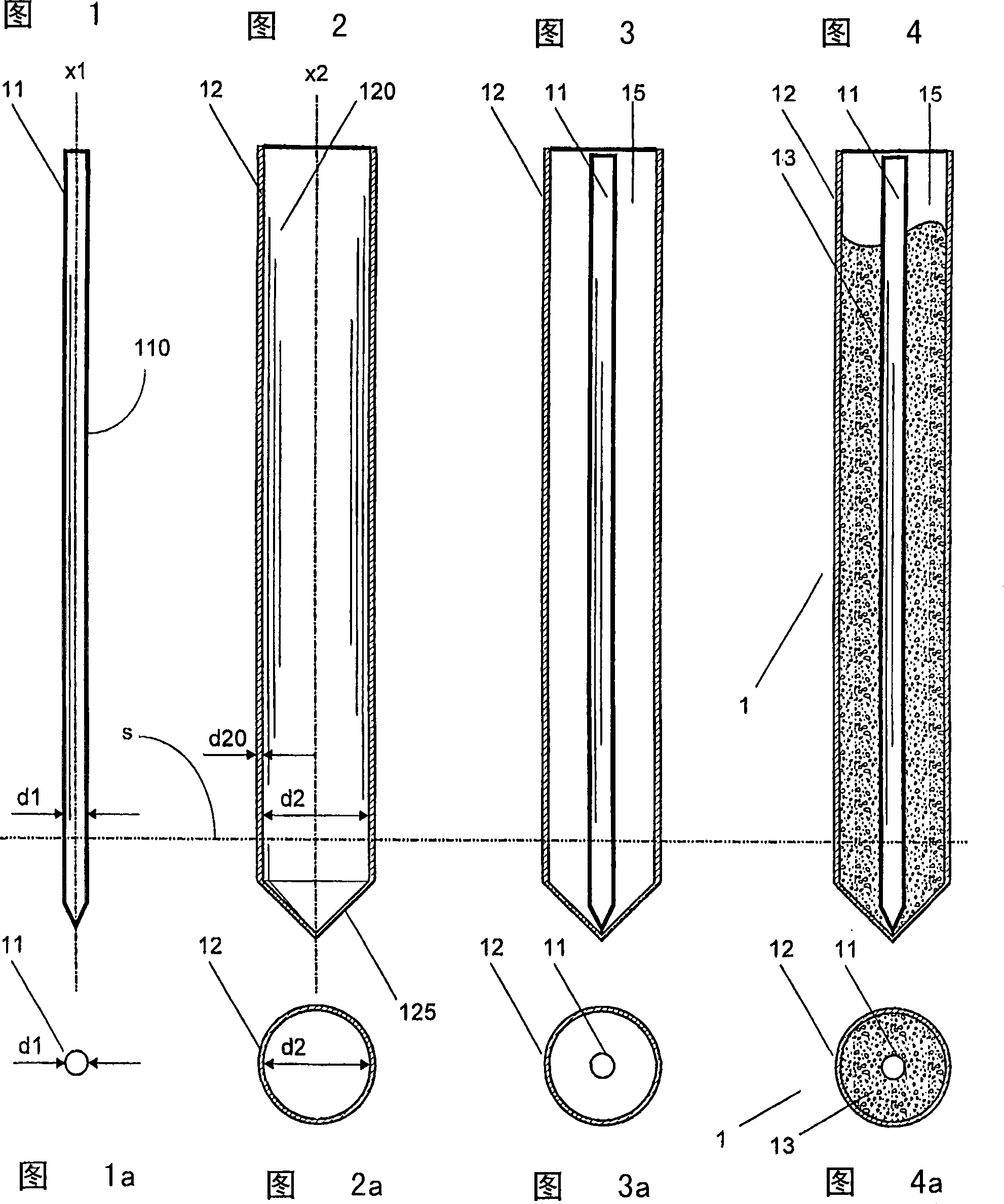

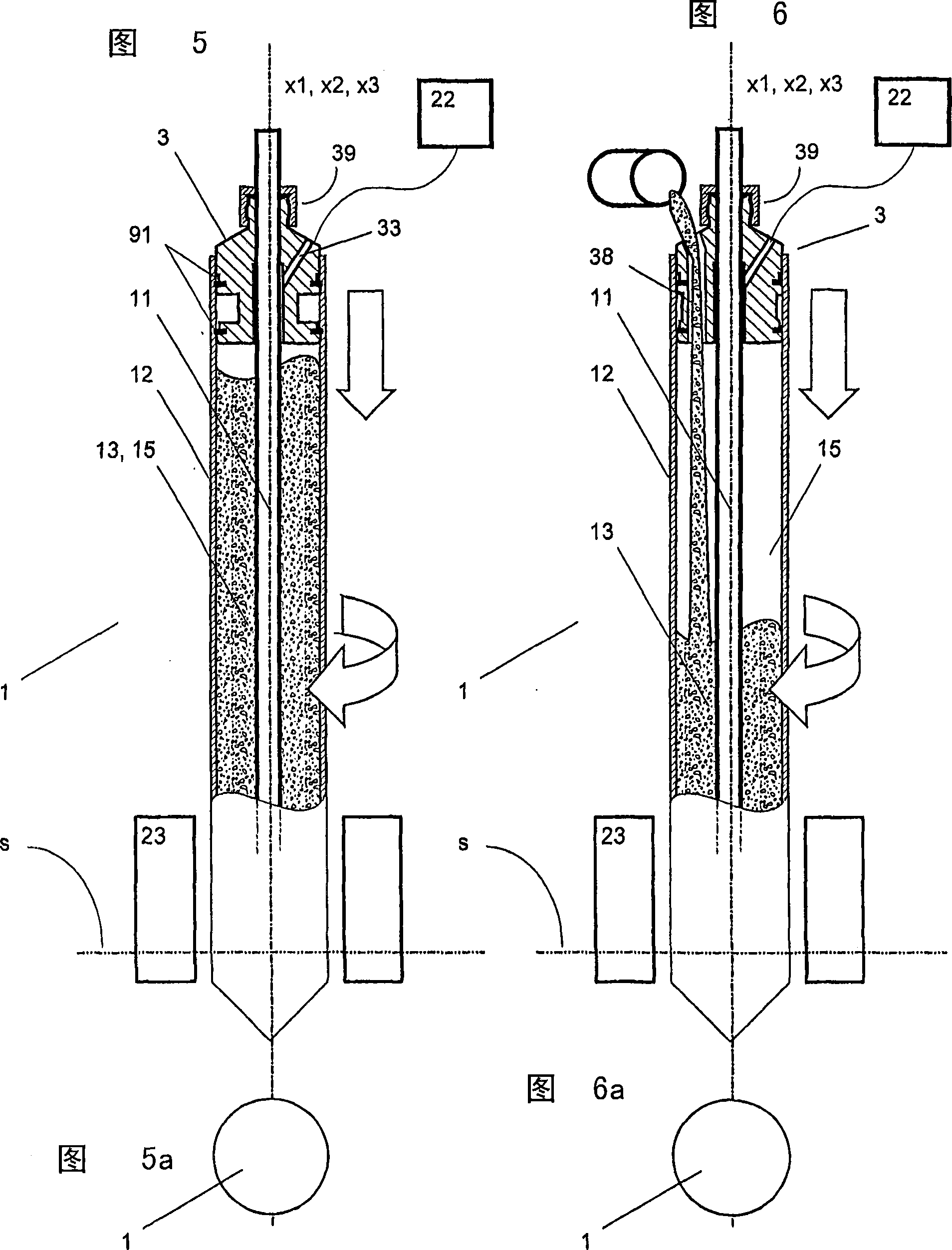

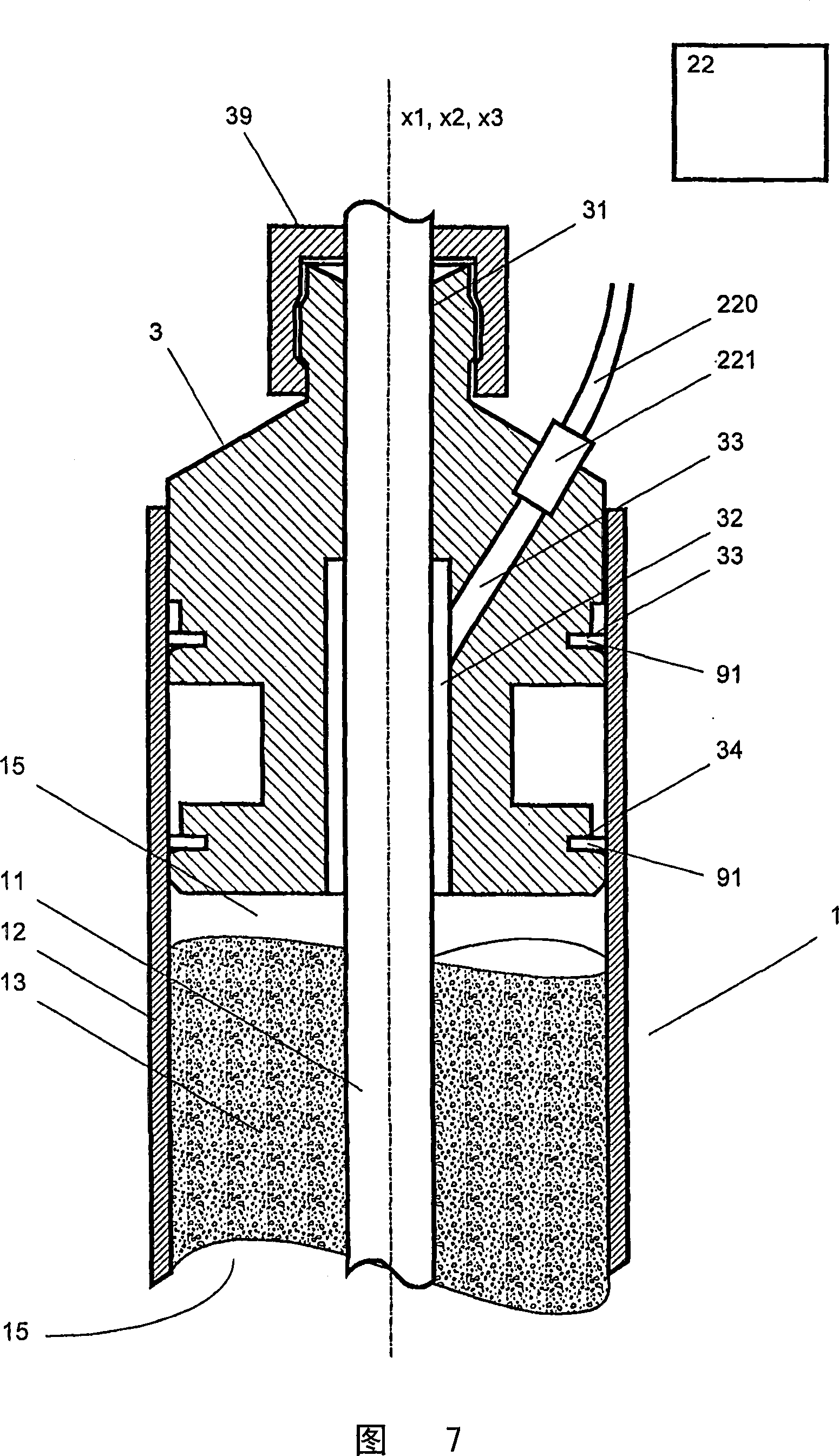

[0093] FIG. 1 shows a primary preform 11 with a first main axis x1 , an outer diameter d1 and an outer surface 111 . The manufacture of such a preform has already been described above.

[0094] FIG. 2 shows a thin-walled silica tube 12 having a first major axis x2 , an inner diameter d2 , an outer diameter d20 and an inner surface 120 . A thin-walled silica tube 12 comprising a conical shell 125 at its lower end is used as overcladding tube 12 according to the method of the invention. Such silica tubes are available from a number of manufacturers.

[0095] Figure 3 shows the primary preform 11 secured in a centrally inserted position within an overcladding tube 12, wherein said first and second main axes x1, x2 are substantially aligned with each other.

[0096] The diameter d20 of the circular wall of the outer cladding tube 12 is, for example, 10 times smaller than its inner diameter d2. However, the ratio of diameter d2 / d20 can be as high as 50 or more. The ratio d2 / d1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com