Driving system and driving device for yarn carrier of spinning machine

A driving device and a technology for textile machinery, which are applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, etc., can solve the problems of reducing wiring space, reducing the number of control signal transmission lines, and complicated wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

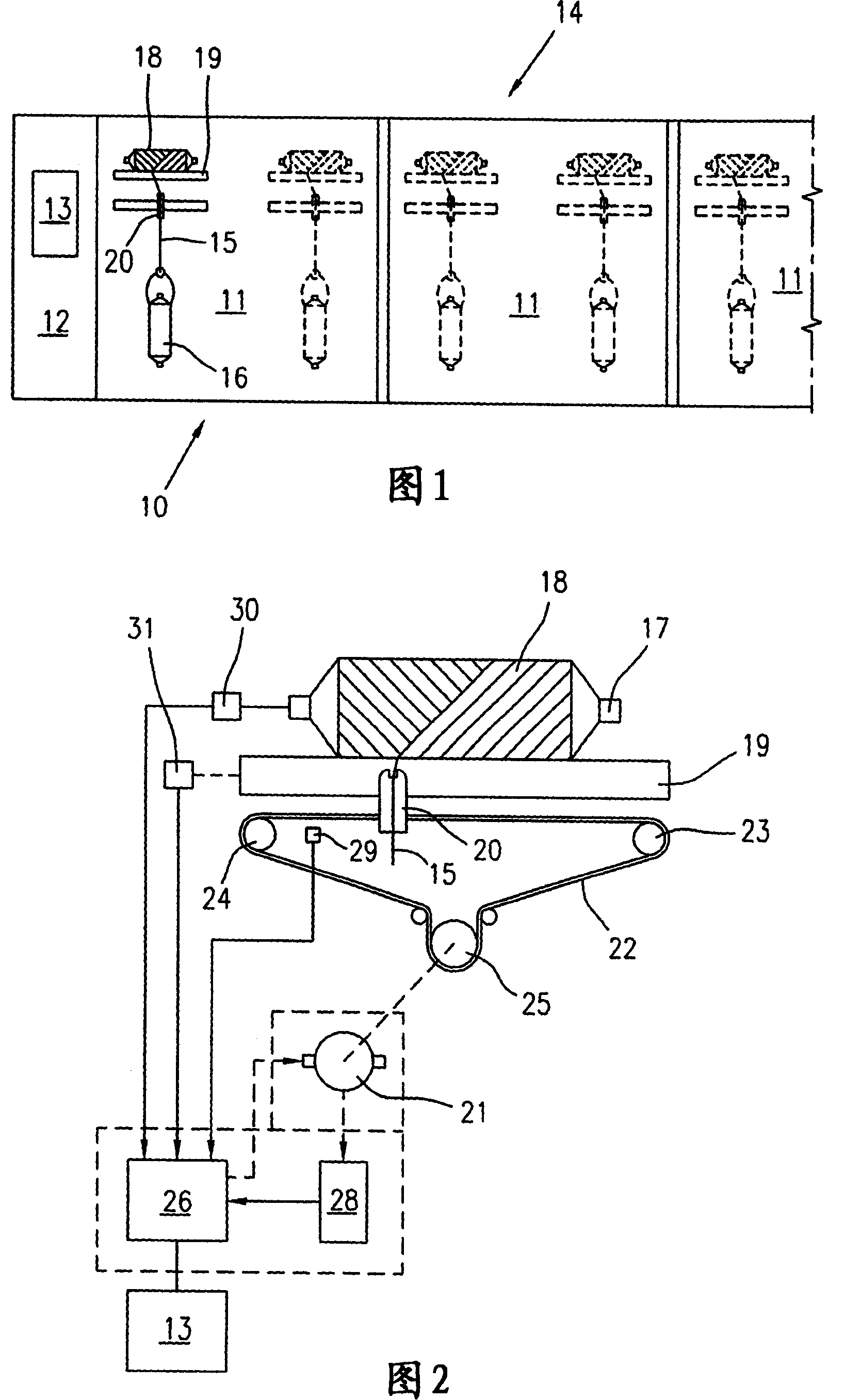

[0029] figure 1 Indicates a part of a textile machine, such as a winder, equipped with an integrated drive and control system for yarn guides as described in this invention.

[0030] As shown in the figure, the machine (10) includes a plurality of side-by-side combination units (11), and one end (12) of the machine is equipped with an electronic master control device (13), which controls each station (14) of the whole machine.

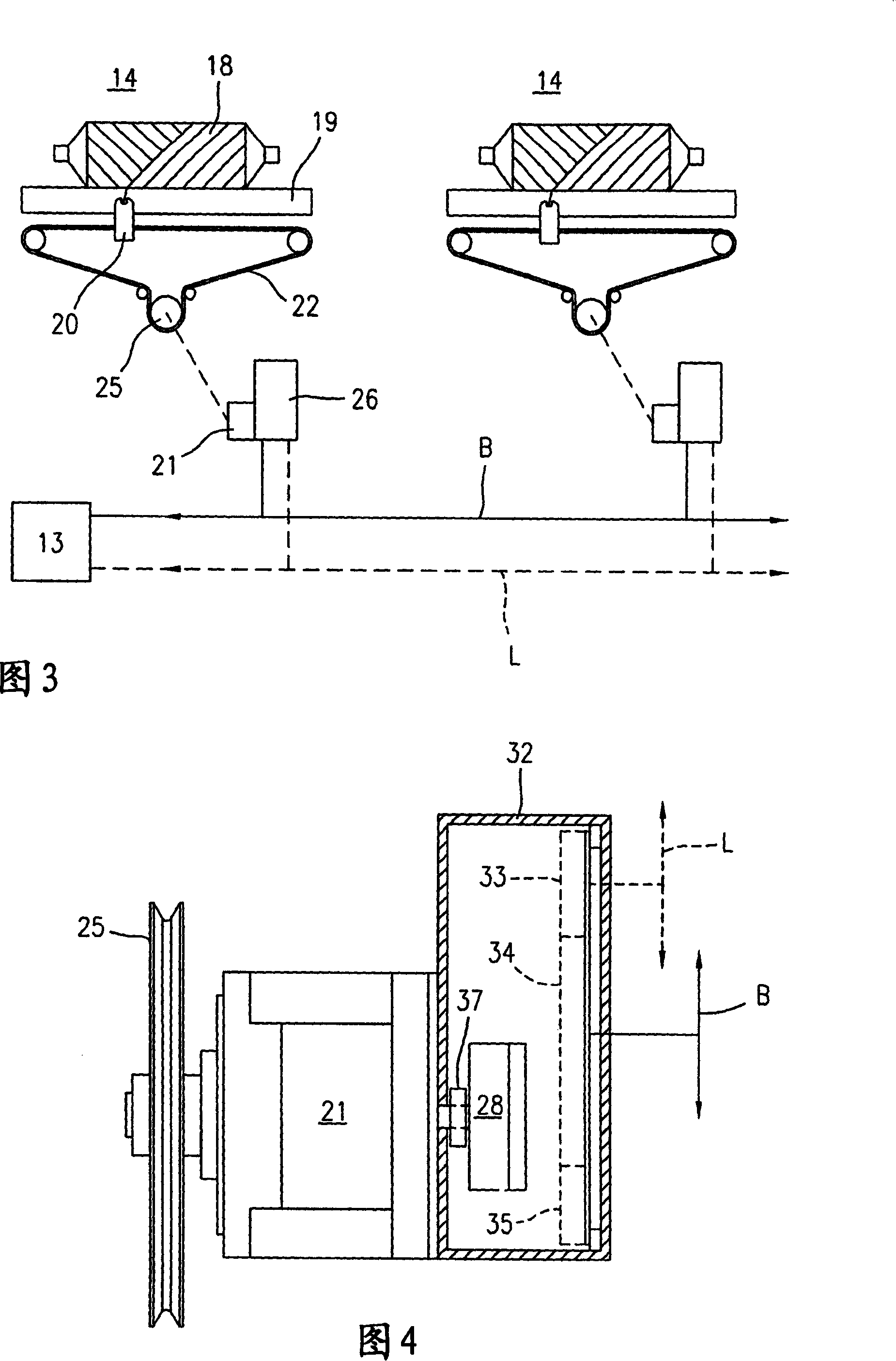

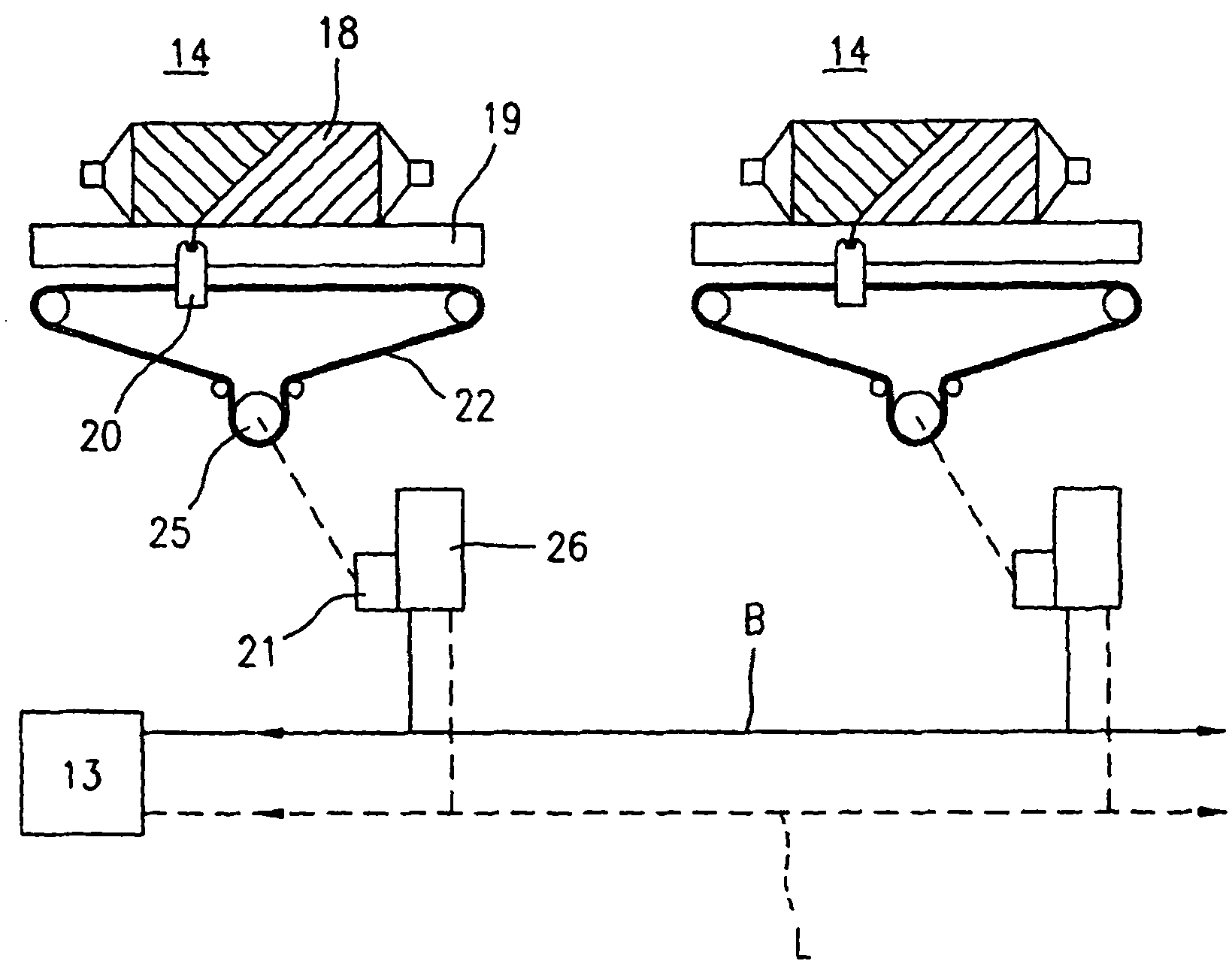

[0031] as indicated figure 1 ,example figure 2 and example image 3 As shown, in each station (14), the yarn (15) is wound from the bobbin (16) onto the bobbin (17) to form the bobbin (18). A direct control device (30) with a speed transmitter - or a pulling roller (19) - drives the bobbin to rotate around its own axis,

[0032] The yarn guide (20) reciprocates along the set working stroke to guide the yarn (15) to be wound onto the bobbin (18).

[0033] The yarn guide (20) can be connected with the control motor (21) in any mechanical transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com