Connector for transfer heavy load

A coupling device, heavy load technology, applied in the direction of coupling, key connection, connecting components, etc., can solve the problems of shortening the service life of the spline, increasing the pressing force, etc., achieving good reliability and eliminating gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

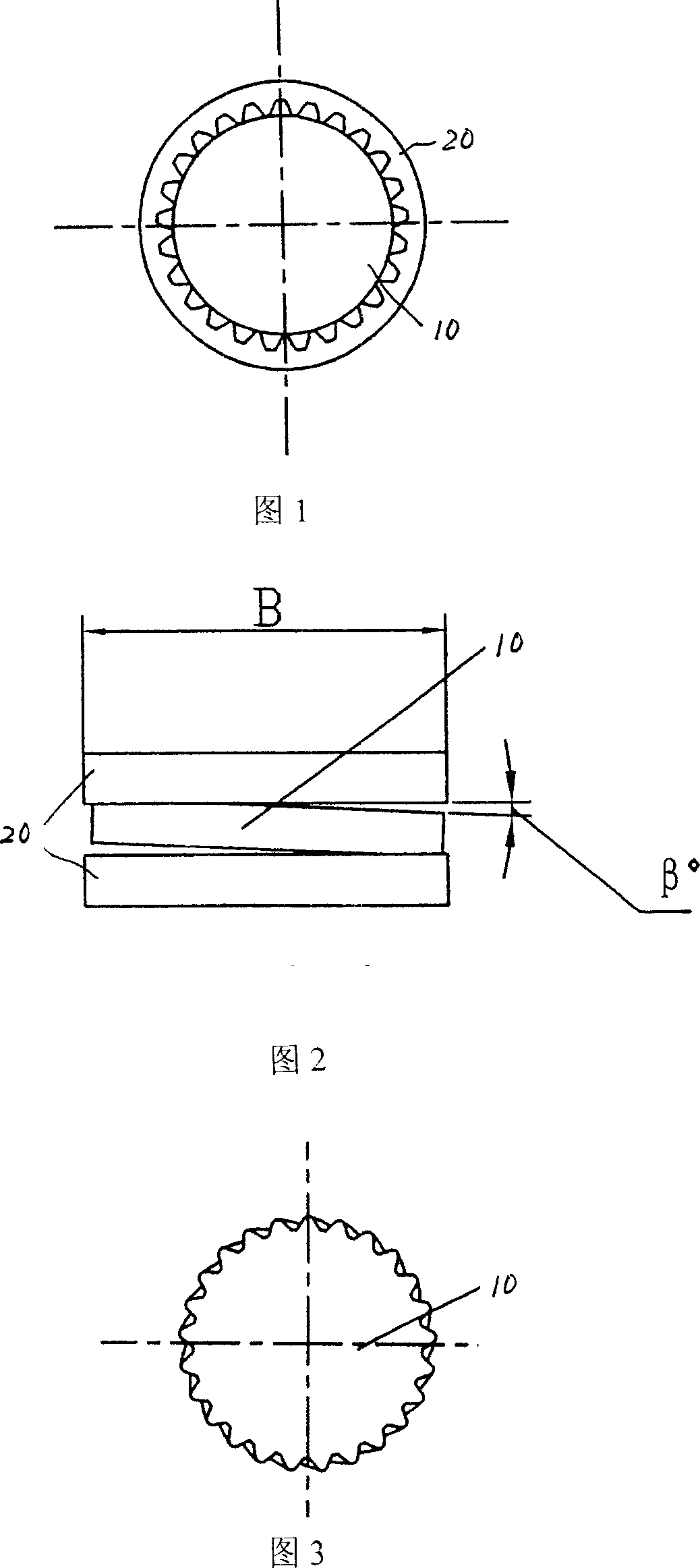

[0009] The coupling device for transferring heavy loads of the present invention includes inner and outer splines 10, 20, one of which is a straight spline, and the other is a small-angle helical spline.

[0010] The internal spline 10 is a helical spline.

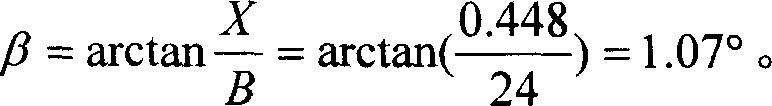

[0011] The helix angle of the spline is a function of the interference amount and the tooth width, that is to say, the helix angle can be determined according to the interference amount, and the calculation formula is as follows:

[0012] β = arctan X B

[0013] β: is the helix angle

[0014] X: To increase the amount of interference through the helix angle

[0015] When this method is used to connect, the spline fit mostly adopts clearance fit.

[0016] Large bevel gears are used in the transfer case and the rear axle of the car. The torque transmitted by the bevel gear to the shaft can be as high as 2000N*M. It must be connected by bolts or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com