Double work position steel bar cold bending test machine

A cold bending test and double-station technology, which is applied in the direction of applying stable bending force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of large manpower, long time, complicated equipment and difficult operation, etc., and improve work efficiency , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

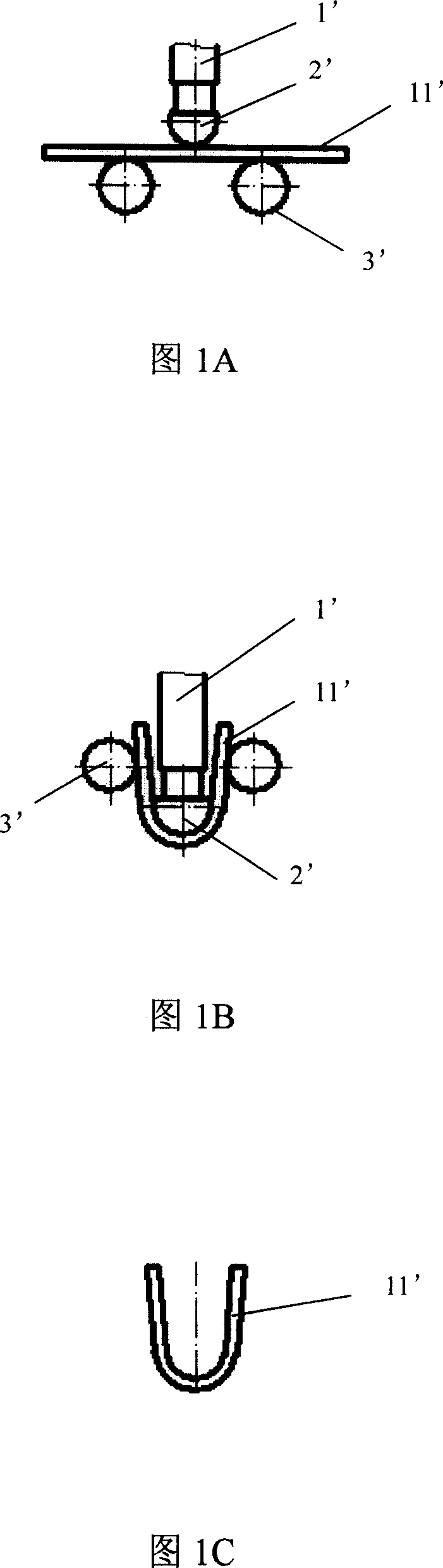

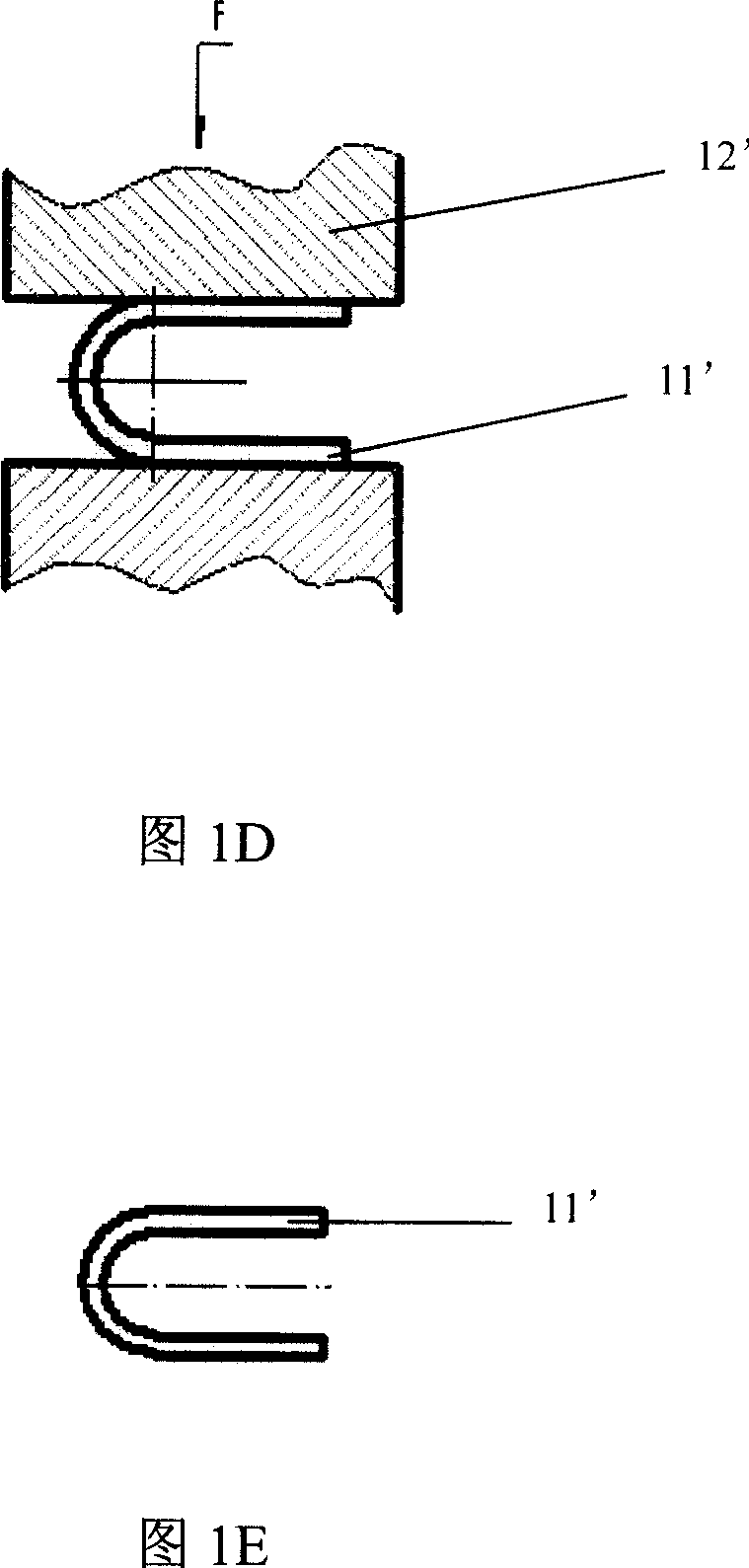

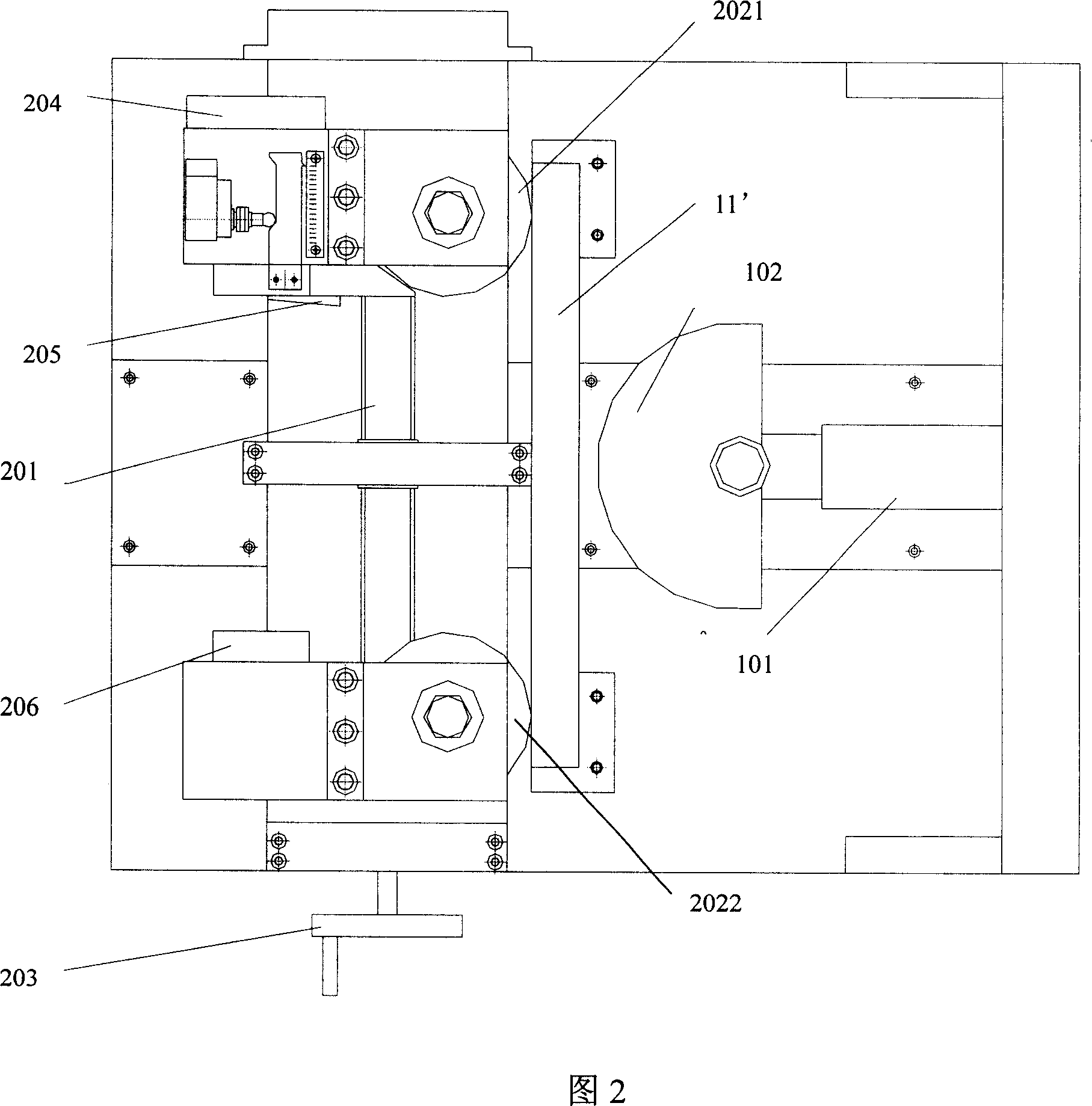

[0029] As shown in Figures 2 to 4, a double-station steel bar cold bending test machine provided by the present invention includes a force applying device and a force bearing device;

[0030] The force applying device includes a main cylinder piston rod 101 and a bend 102 installed at the top end of the main cylinder piston rod, and the force bearing device includes an adjustable support device and an interference loading device;

[0031] The piston rod 101 of the main oil cylinder can drive the bending center 102 to move back and forth;

[0032] There are several standards for the diameter of the bending core 102, which can be changed according to the different requirements of the diameter of the sample 11';

[0033] The adjustable supporting device includes a lead screw 201 and supporting rollers 2021 and 2022 installed at both ends of the lead screw 201. Further, one end of the lead screw 201 is also connected with a handle 203, and the handle 203 is shaken to drive the lead sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com