Device for realizing light beam automatic shaping using shape changing lens

A deformable mirror, beam technology, applied in optics, optical components, instruments, etc., to achieve the effect of large dynamic travel range, small nonlinear lag, and correction of high-order aberrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

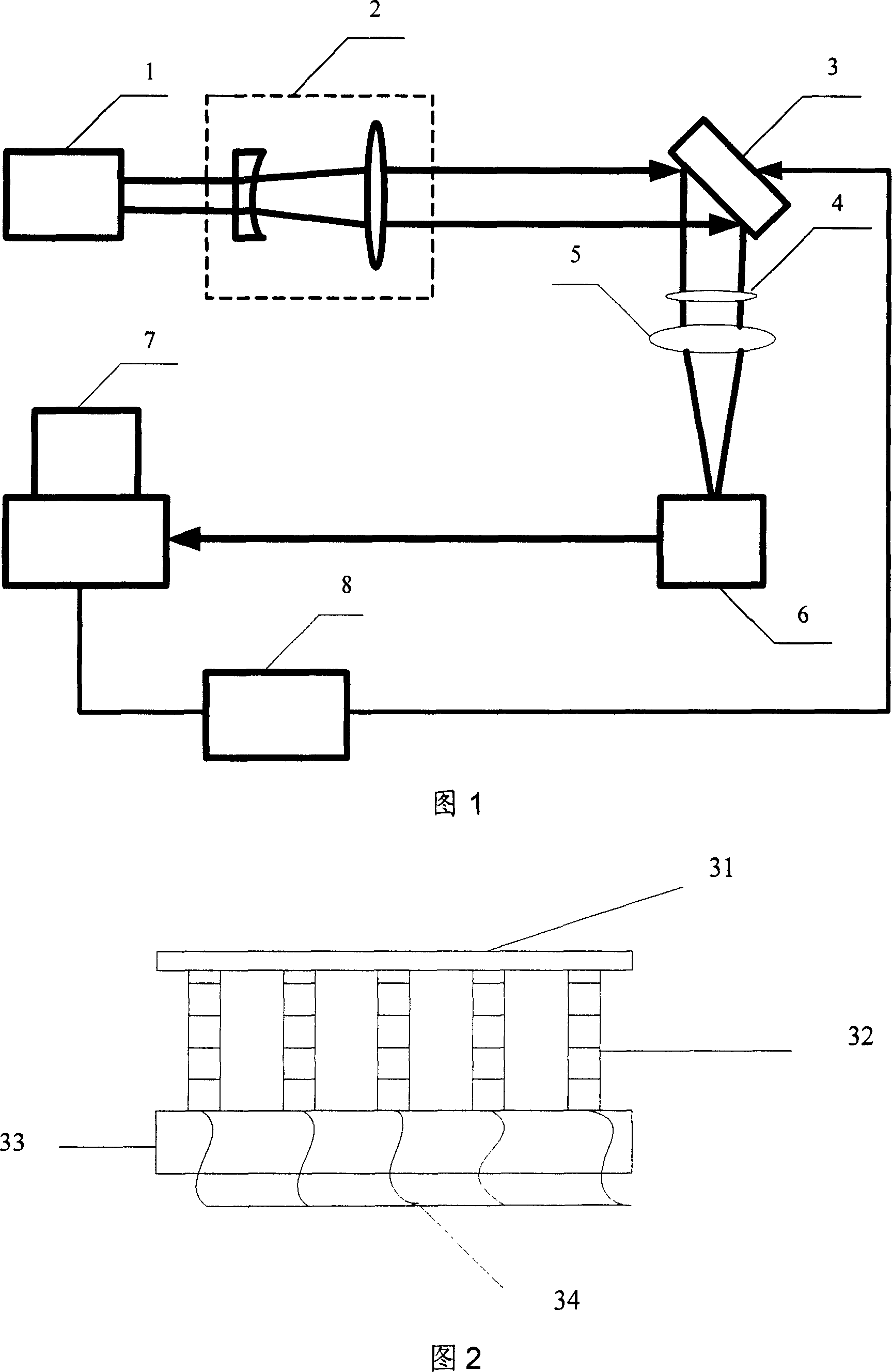

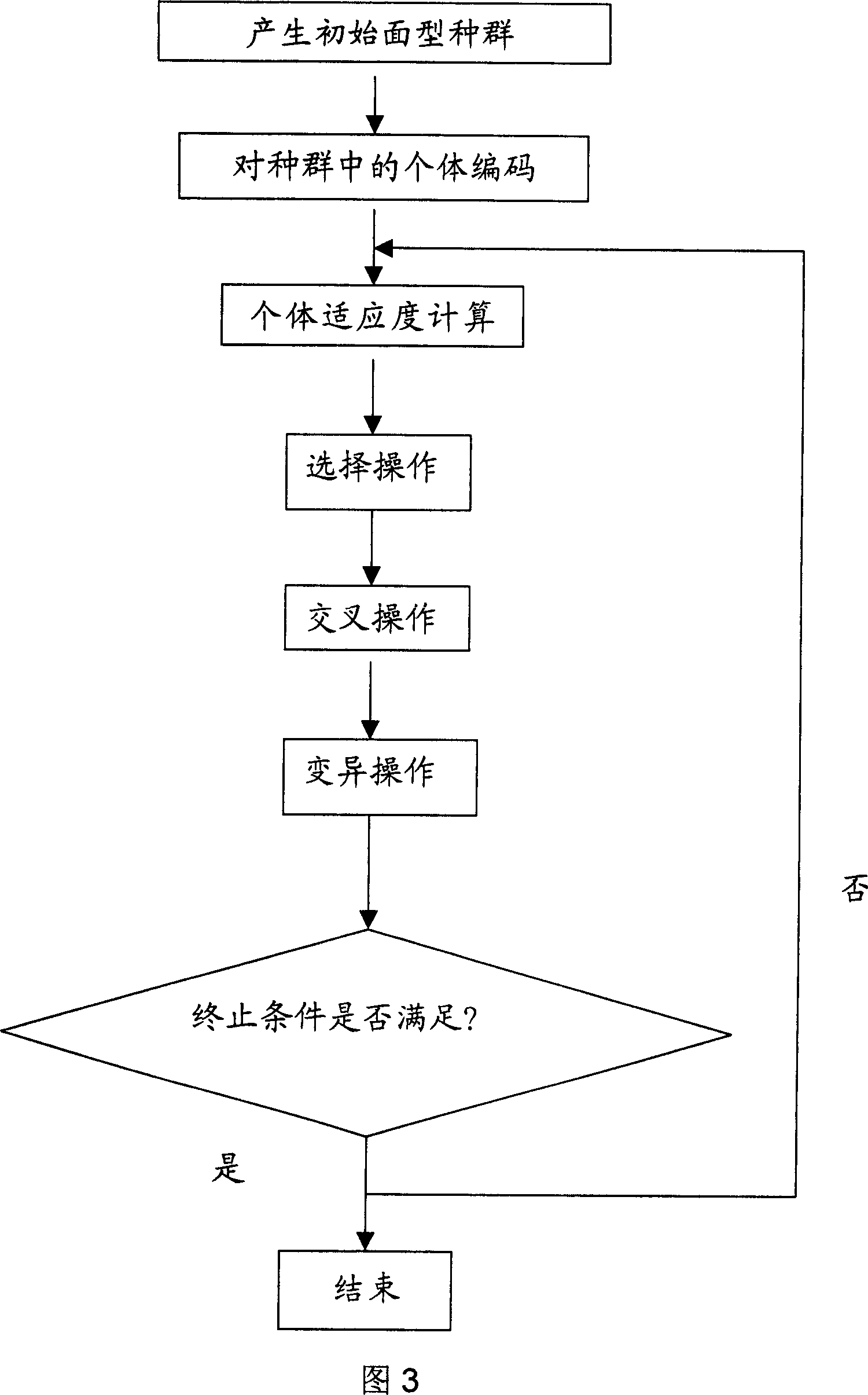

[0025] As shown in Figure 1, the device of the present invention that utilizes a deformable mirror to realize automatic beam shaping mainly includes a laser 1, a telescope 2, a deformable mirror 3, a variable density attenuation disk 4, a focusing lens 5, a CCD camera 6, a main control computer 7 and built-in other The internal image acquisition card, the control software based on genetic algorithm, the high-voltage amplifier 8 and the built-in D / A conversion card are composed. The output beam of the laser 1 is enlarged by the telescope 2 to match the aperture of the deformable mirror 3, and the beam is deformed. The mirror 3 is attenuated by the variable density attenuation disk 4 after reflection, then is incident on the focusing lens 5, and is converged on the target surface of the CCD camera 6 on the focal plane. The light spot signal on the surface is collected, and the absolute difference operation is performed on the corresponding pixel by using this signal and the targe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com