Permanent magnet mechanism contactor with parallel magnetic path

A permanent magnet mechanism and contactor technology, applied in electromagnetic relays, electromagnetic relay details, circuits, etc., can solve the problems of reducing electromagnetic force, failure to achieve voltage-loss breaking, cost-consuming, etc., and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

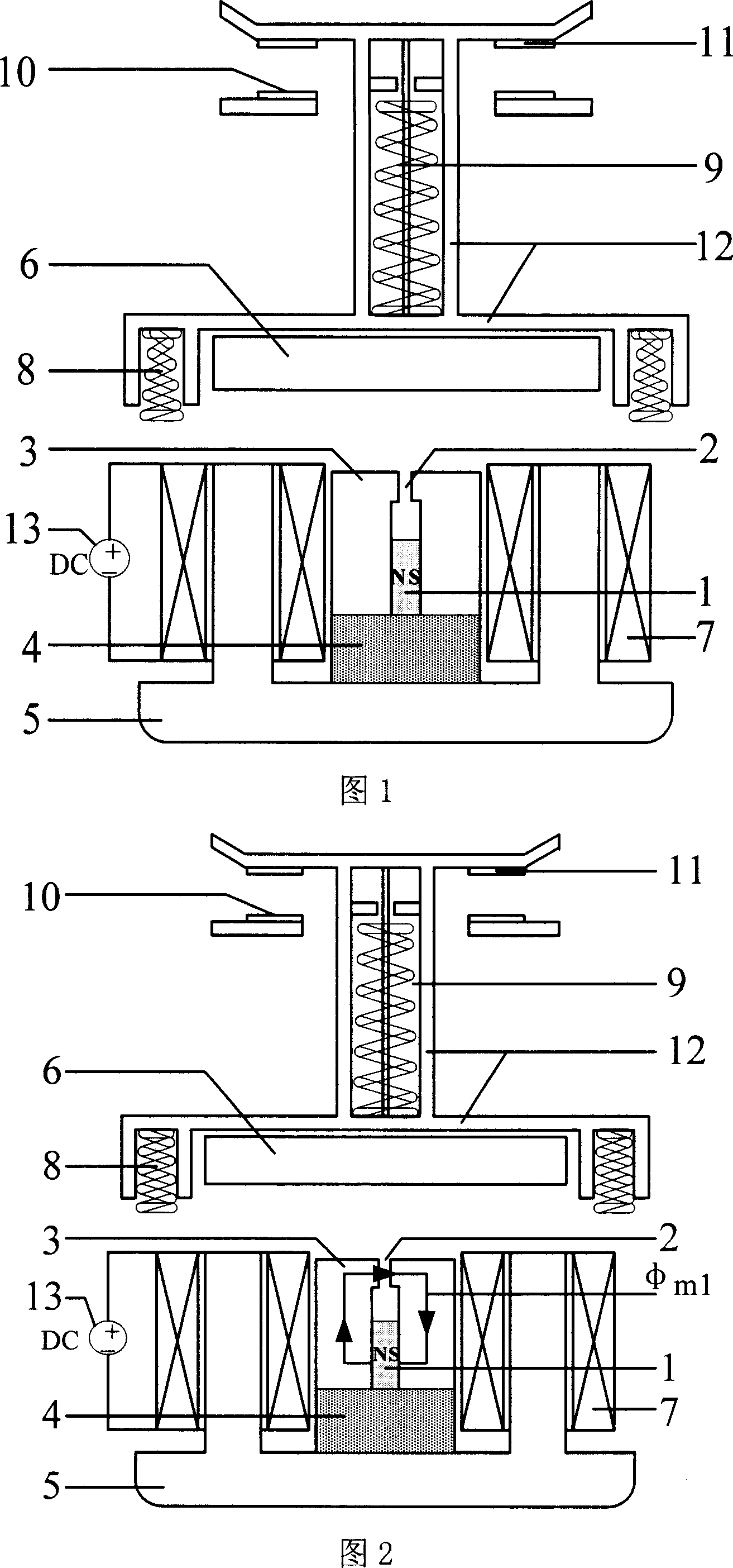

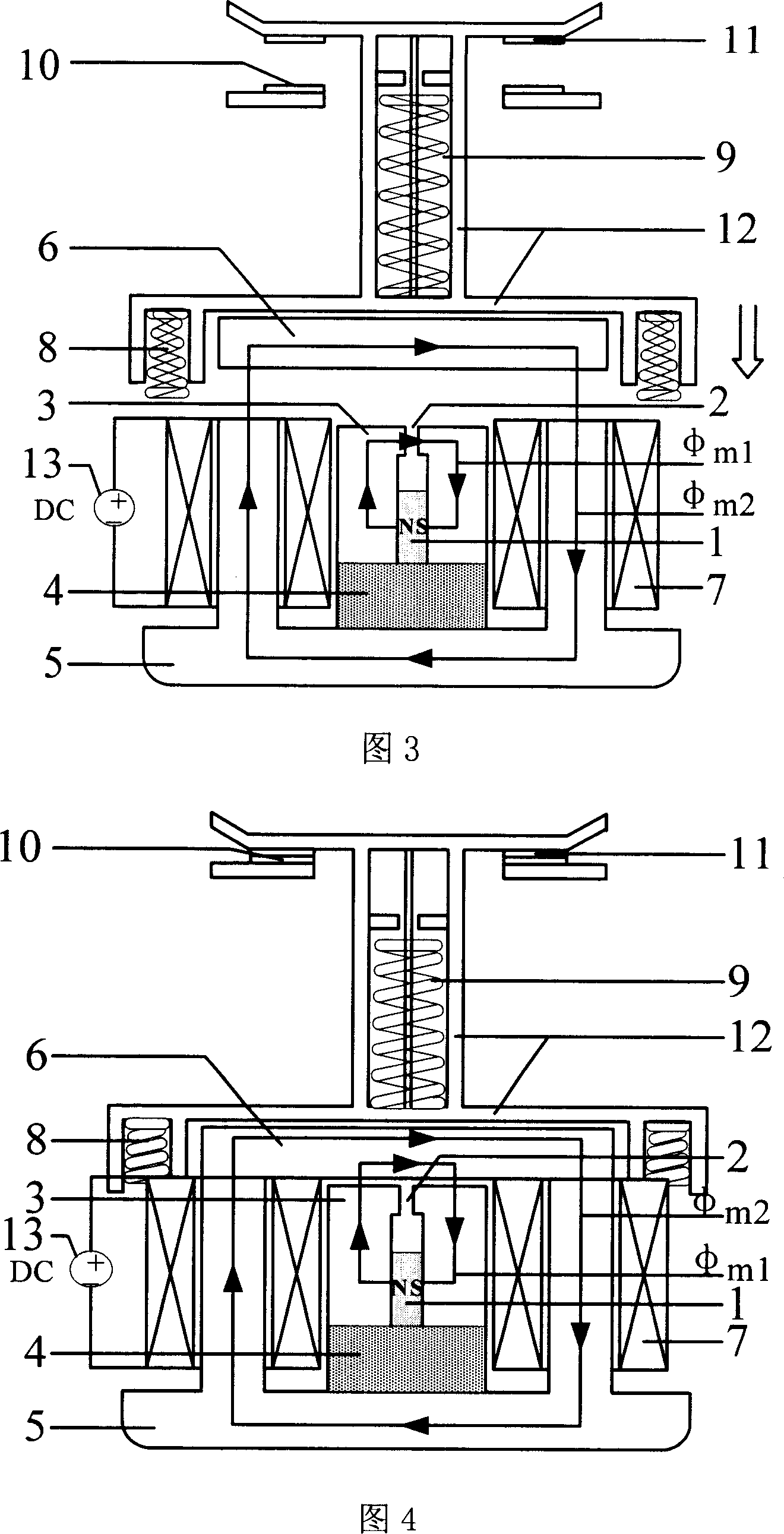

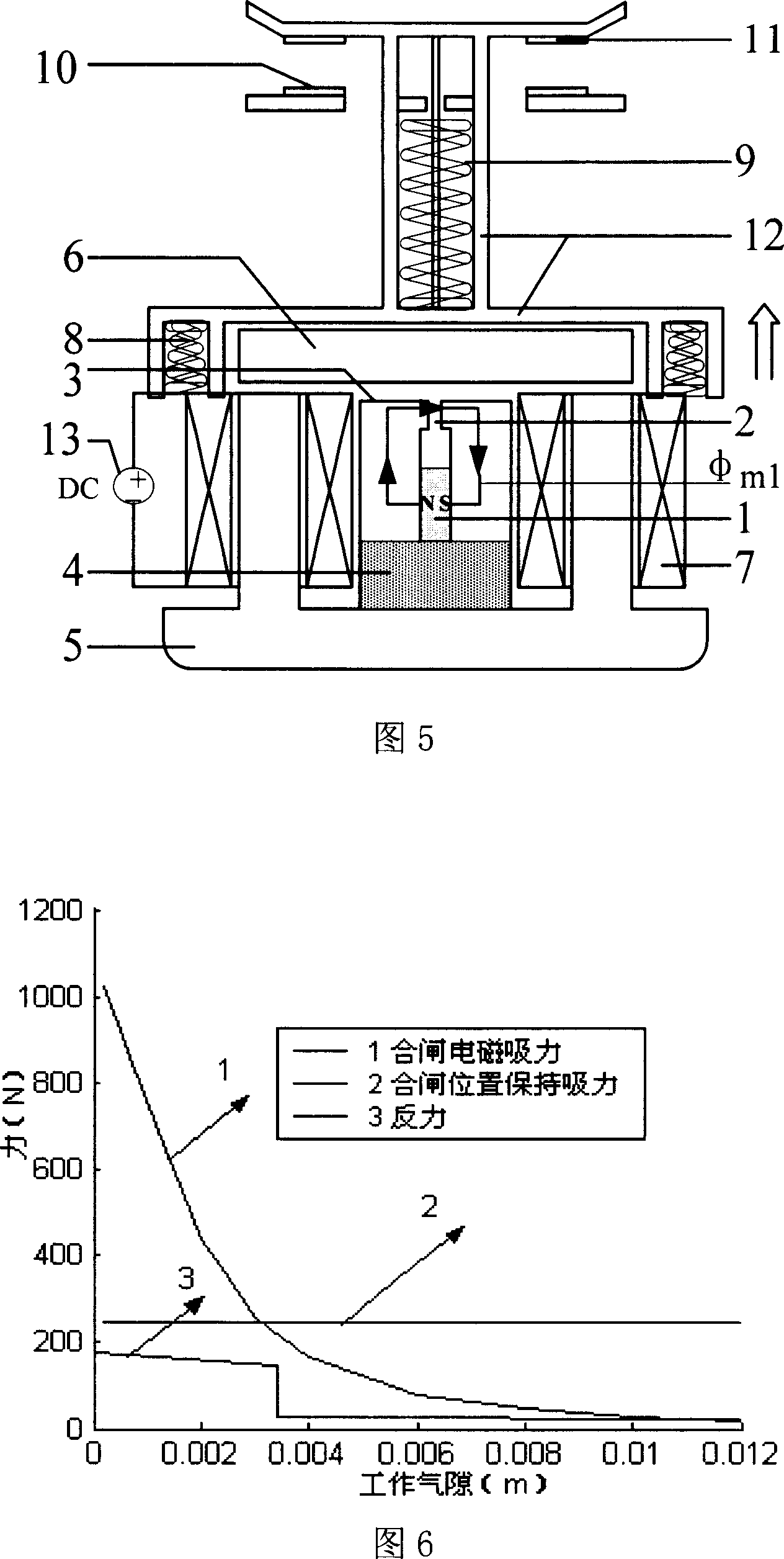

[0037] 1. The overall idea of the technical solution

[0038] Reducing the working energy and power consumption of contactors and improving the working reliability of contactors have always been the important goals of contactor research. So far, neither the traditional electromagnetic contactor nor the existing permanent magnet contactor has satisfactorily solved this proposition. The design concept of the present invention is to propose a new permanent magnet mechanism contactor with a parallel magnetic circuit to realize the energy saving of the permanent magnet mechanism contactor and the function of voltage loss protection without the need for a voltage loss protection device.

[0039] 1) A new permanent magnet mechanism contactor with a parallel magnetic circuit:

[0040] At present, many types of permanent magnet mechanism contactors for energy saving have been developed, but because the previous energy-saving permanent magnet mechanism contactors have no pull-in and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com