Gas wall electrode side connection phase shift storage and its producing method

A manufacturing method and phase change technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, circuits, etc., can solve problems such as power consumption, increase in parasitic resistance, component uniformity and reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

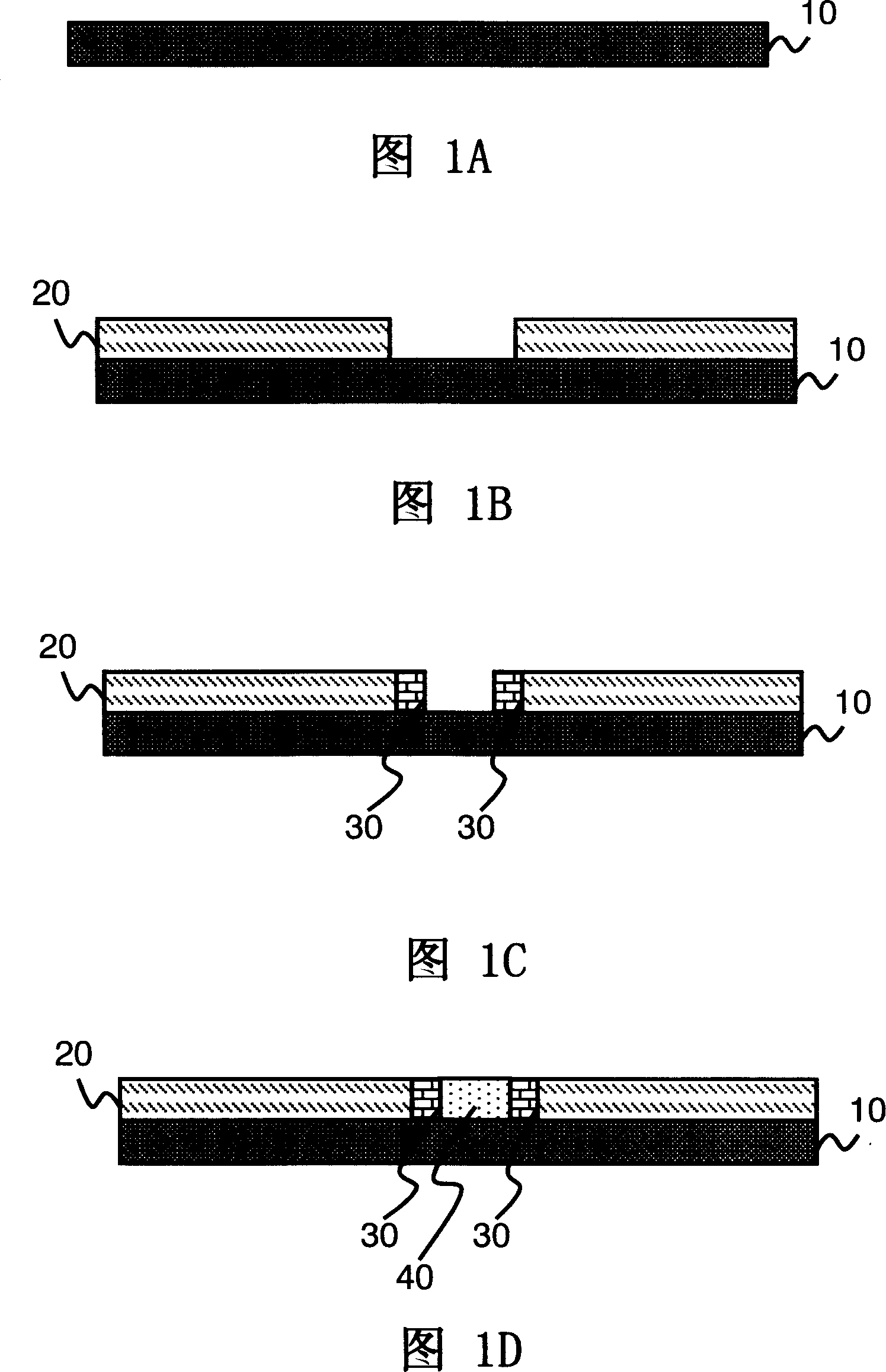

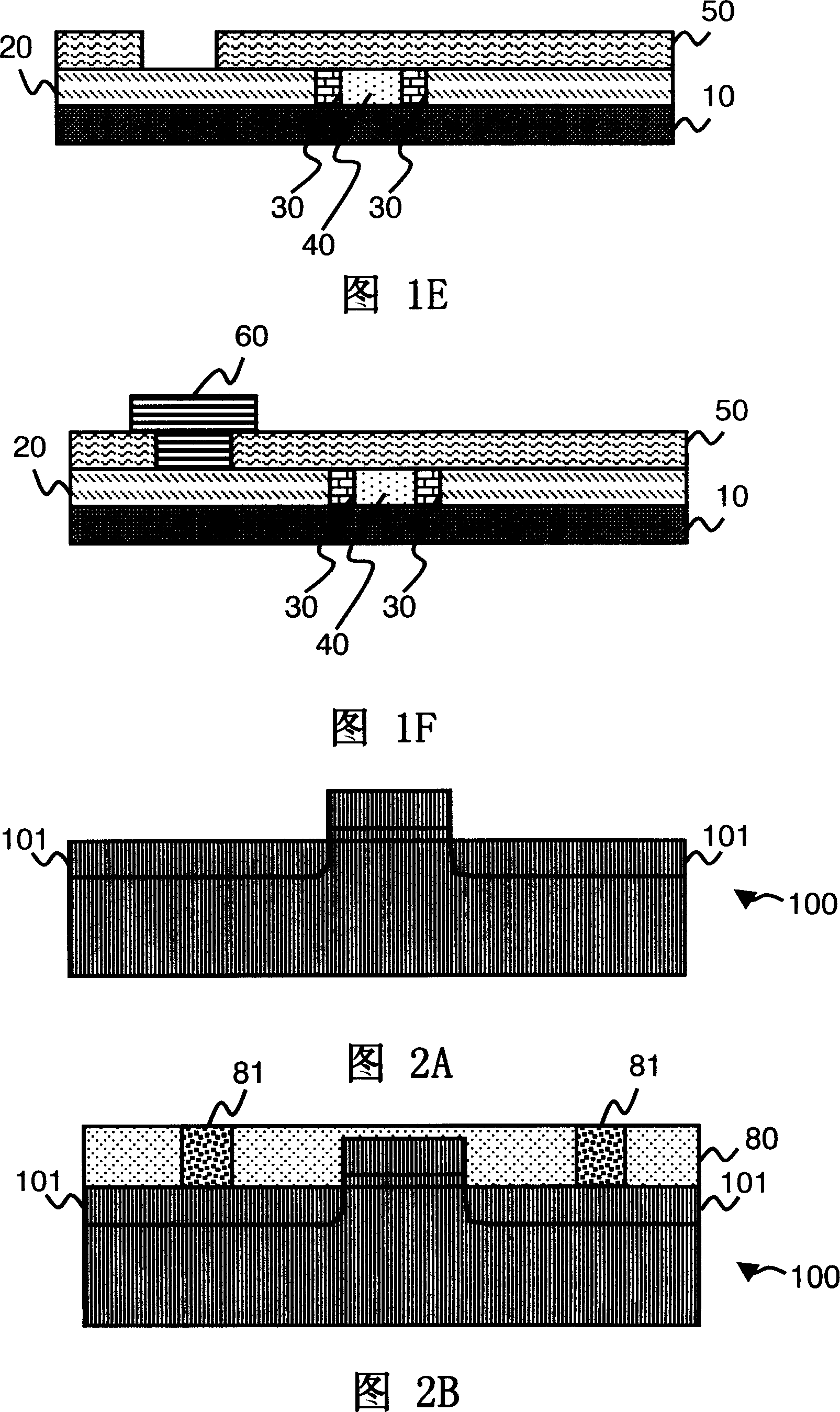

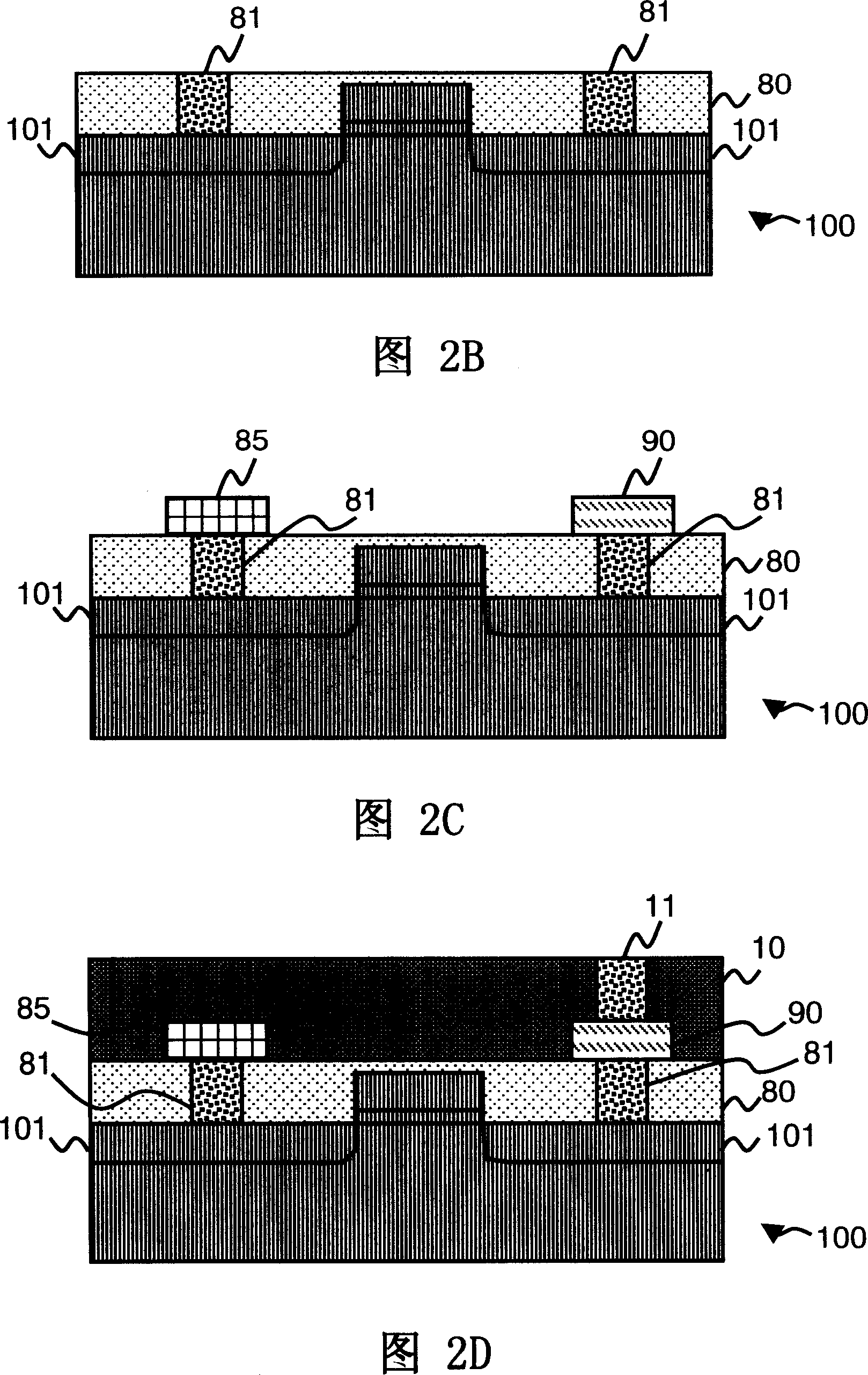

[0037] In the known phase change memory, the conductive region and the phase change material layer 40 are stacked on each other, the phase change material layer 40 is parallel to the surface of the substrate, and one or more channels pass through the insulating layer to expose the conductive region. The area of the channel is used to determine the electrical contact area between the conductive region and the phase change material layer 40 , and the plane of the contact region is parallel to the substrate. The minimum size of the channel (i.e. the minimum contact area) is mainly determined by the photolithography process, and the area of the channel will determine the operating current flowing vertically into the phase change material layer 40, which is to determine whether to set or reset the phase change material layer 40. Therefore, in the known practice, the operating current of the phase change memory is mainly limited by the capability of the photolithography process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com