Composite technique for preparing ammonia, methanol and carbon monoxide

A composite process, carbon monoxide technology, applied in the direction of carbon monoxide, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of waste of chemical raw materials and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

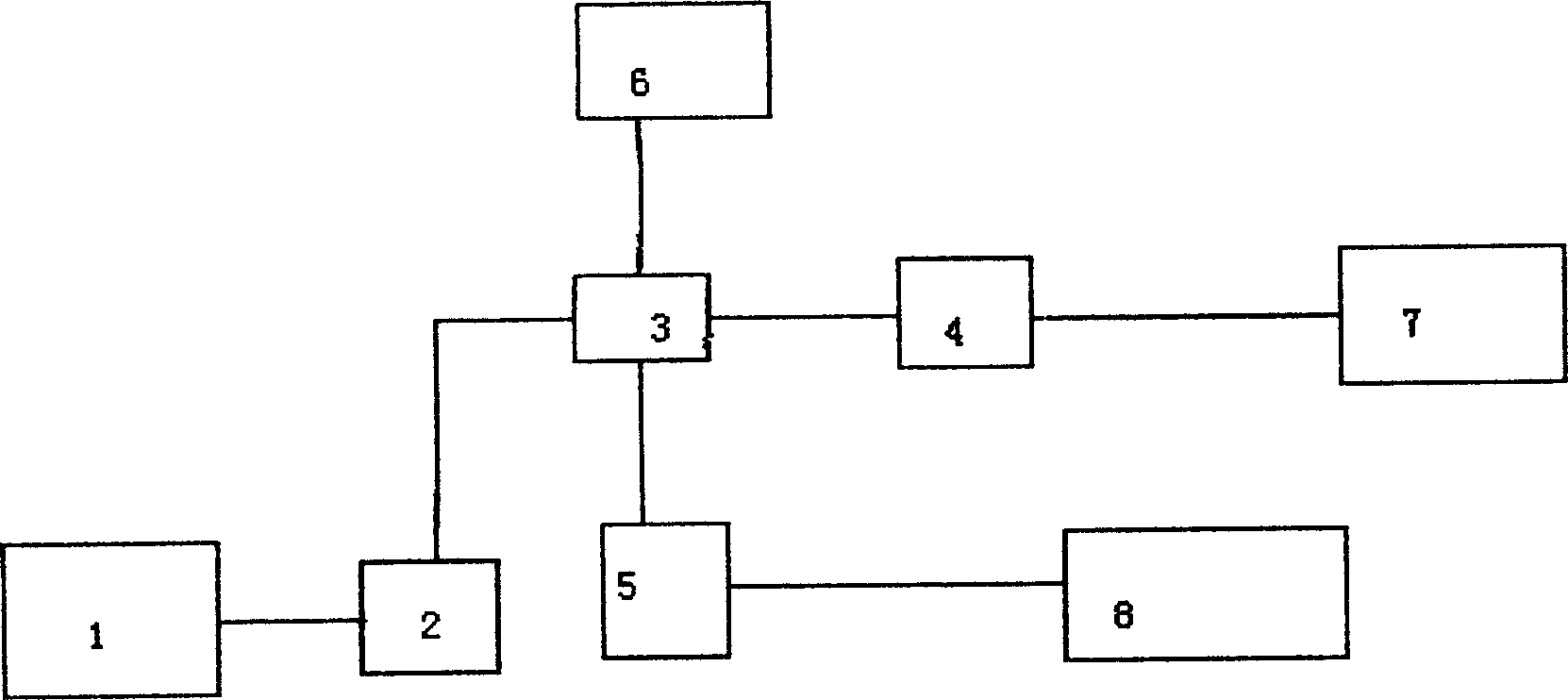

[0034] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0035] The present invention provides a composite process for producing raw materials of ammonia, methanol and carbon monoxide, which adopts the following process steps: 1. the water gas produced by the water gas generator 1 is imported into the converter, and its volume percentage is composed as follows:

[0036] Composition %VOL

[0037] h 2 32.50~36.57

[0038] CO 47.37~51.52

[0039] CO 2 12.38~16.43

[0040] COS+H 2 S 0.77~1.93

[0041] N 2 0.24~0.61

[0042] CH 4 +Ar 0.11~0.23

[0043] 2. Carry out the methanol washing of the aforementioned water gas produced in the methanol washing tank 3 to remove impurities such as hydrogen sulfide and carbon dioxide therein;

[0044] ③ According to the requirements of the hydroxylation process, the one-way water gas washed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com