Semiconductor element with semiconductor component embedded into a plastic housing

A technology for structural components and plastic housings, applied in the fields of semiconductor/solid-state device parts, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of high welding temperature of 260 ° C, improve reliability and prevent the spread of cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

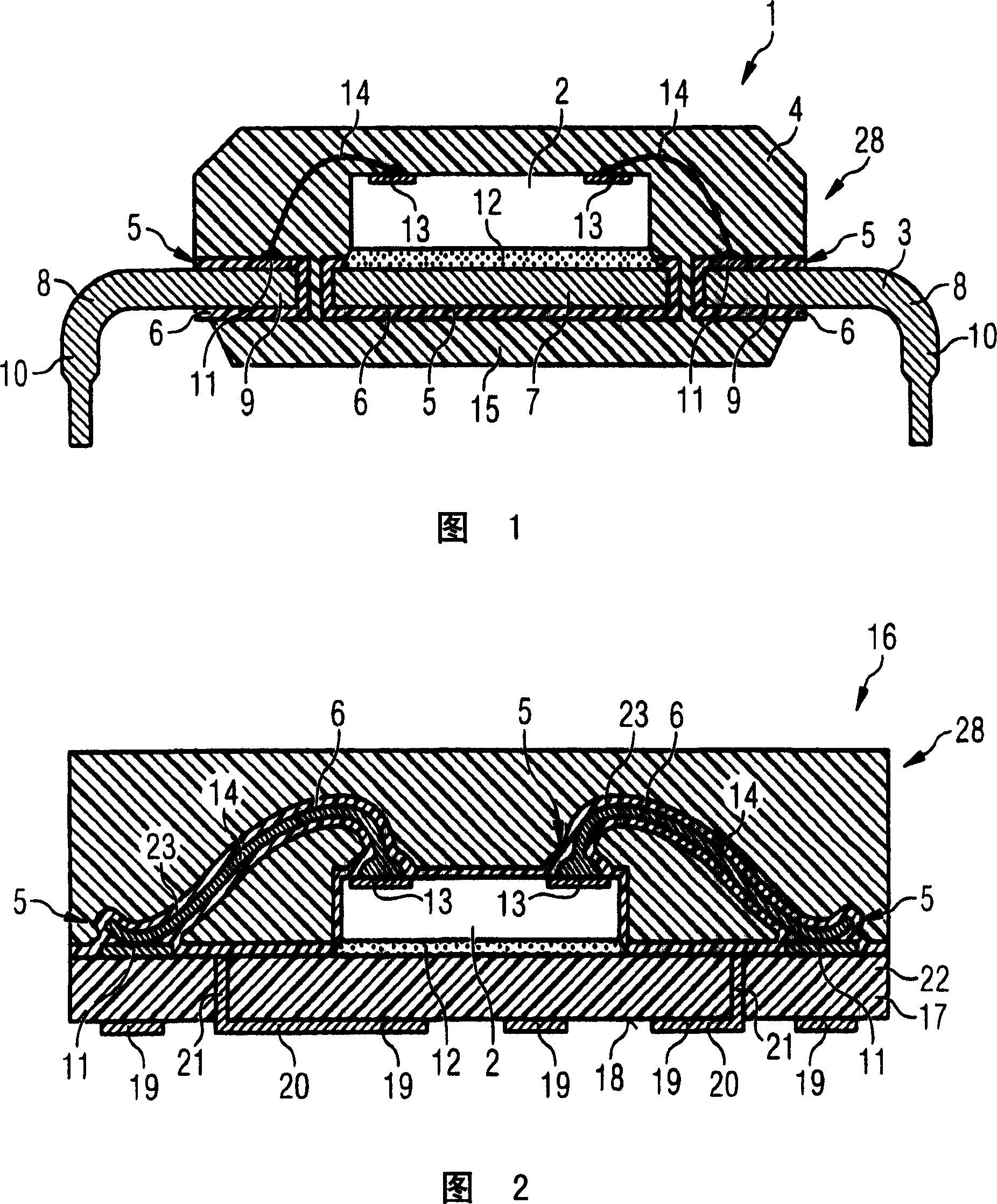

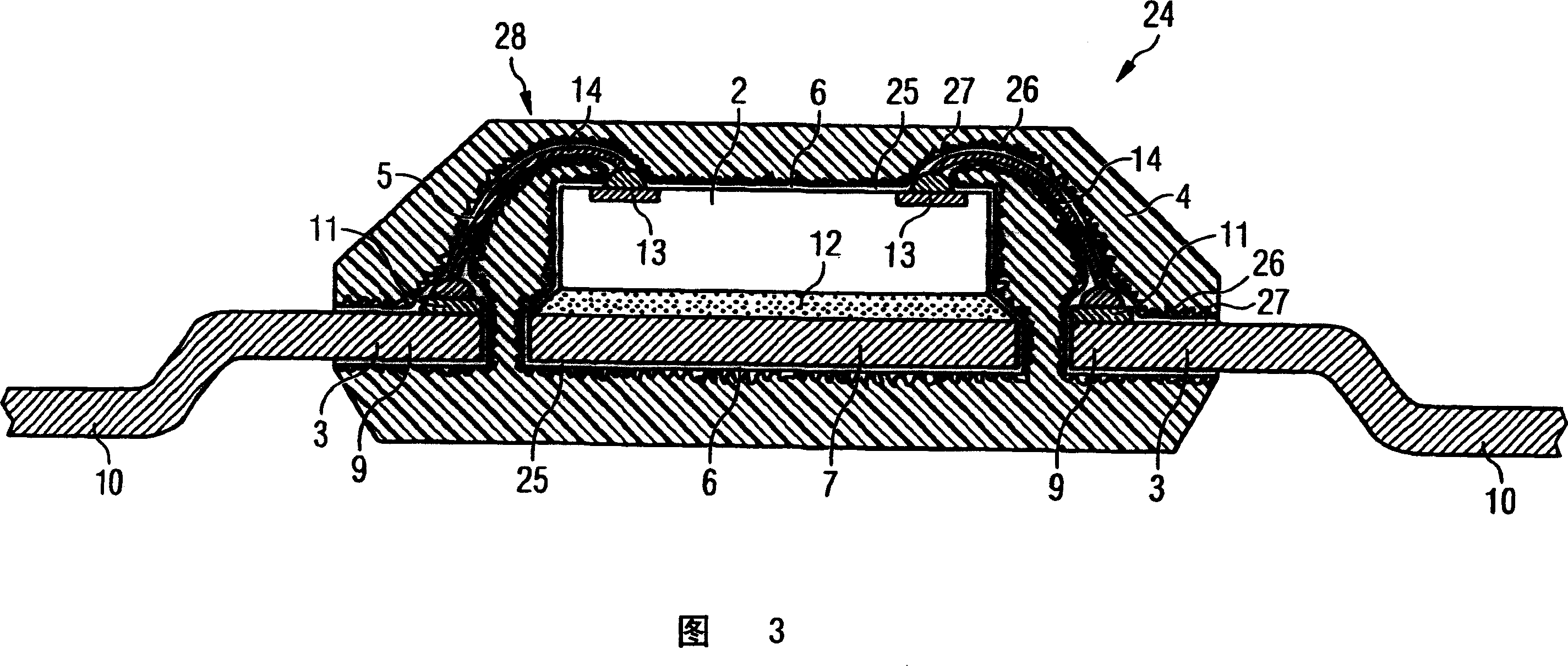

[0050] FIG. 1 shows a cross-sectional view of a semiconductor component 1 with a semiconductor chip 2 and a flat lead frame 3 . The region of the flat lead frame 3 which is embedded in the plastic housing 4 is coated with a buffer layer 5 . The buffer layer 5 is made of a thermoplastic material 6 , which is polyamide 66 in this embodiment.

[0051] The flat lead frame plus 3 has a chip island 7 and a plurality of flat wires 8 surrounding the chip island 7 . Each flat conductor has an inner region 9 embedded in the plastic housing 4 of the component 1 and an outer region 10 located outside the plastic housing 4 . The outer region 10 of the flat conductor 8 defines the external contacts of the semiconductor component, with which the semiconductor component 1 can be mounted on a printed circuit board. The inner region 9 of each flat conductor 8 has an inner contact surface 11 . The flat leadframe 3 has Cu and the inner contact surface 11 has a Ni / NiP layer.

[0052] The inert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com