Laser resonance cavity of the combined full reflection mirror with the right-angle interval and external taper

A technology of laser resonator and total reflection mirror, which is applied in the field of laser resonator, can solve the problems of lower efficiency of resonator, limited compression, difficulty in resonator manufacturing, etc. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

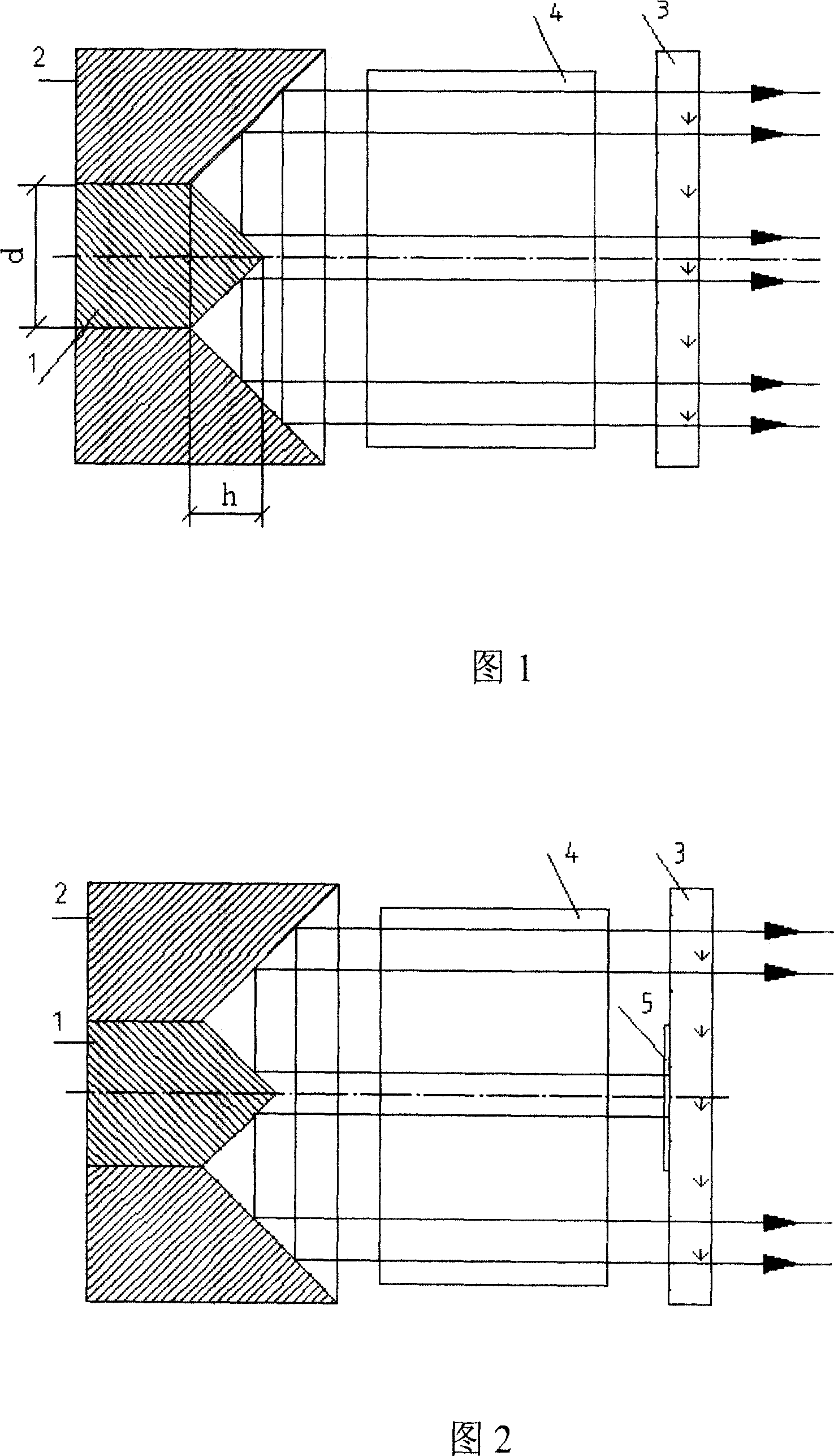

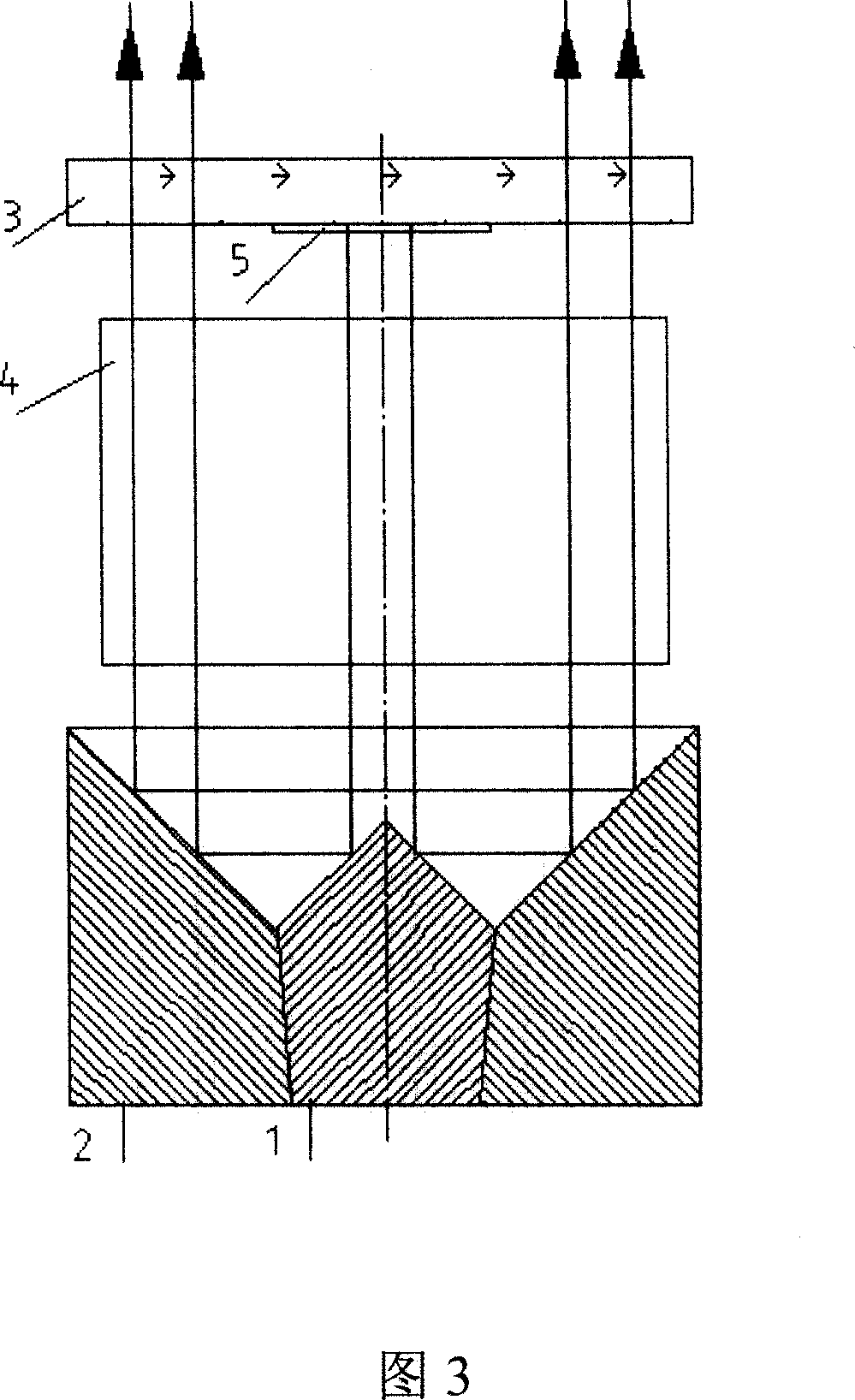

[0019] As shown in Figure 1, a right-angle inner and outer cone combined total mirror laser resonator, including a total mirror, a flat output mirror 3 and a laser working medium 4. The total mirror is a right-angle outer cone mirror 1 and a right-angle inner cone The combination of the surface mirror 2, the outer cone surface of the right-angle outer cone mirror 1 and the inner cone surface of the right-angle inner cone mirror 2 are reflecting surfaces, the right-angle outer cone mirror 1 and the right-angle inner cone mirror 2 The central axes coincide, and the height h of the conical surface of the right-angled outer conical reflector 1 is greater than zero and smaller than the height of the right-angled inner conical reflector 2.

[0020] The vertex of the right-angle outer conical mirror 1 is located on the optical axis of the laser cavity, and its central axis coincides with the optical axis.

[0021] The right-angle outer conical reflector 1 and the right-angle inner conica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com