Building up diffractive optics by structured glass coating

A structured and component technology, applied in the field of optical components, can solve the problems of high cost, time-consuming, low etching rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

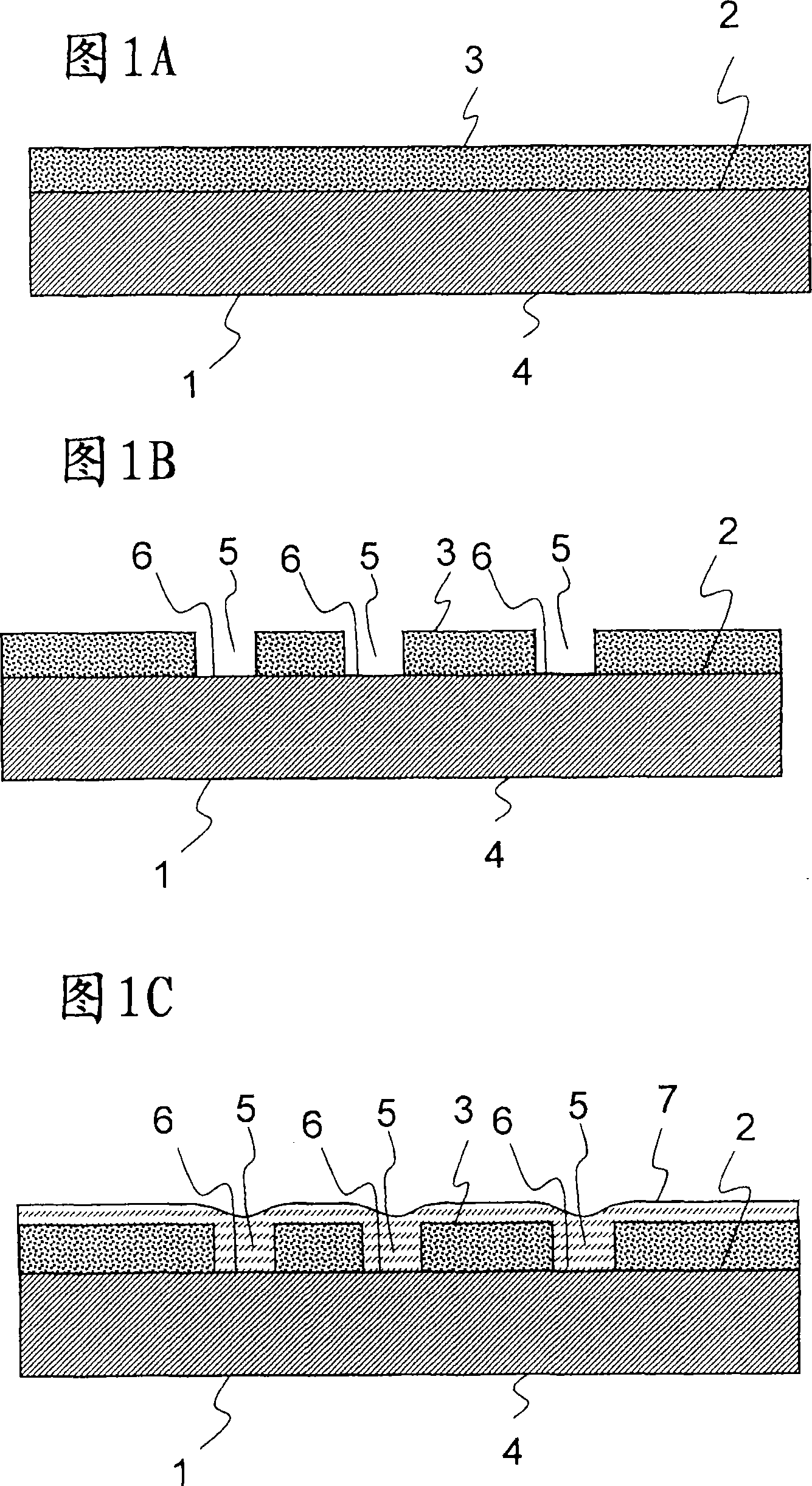

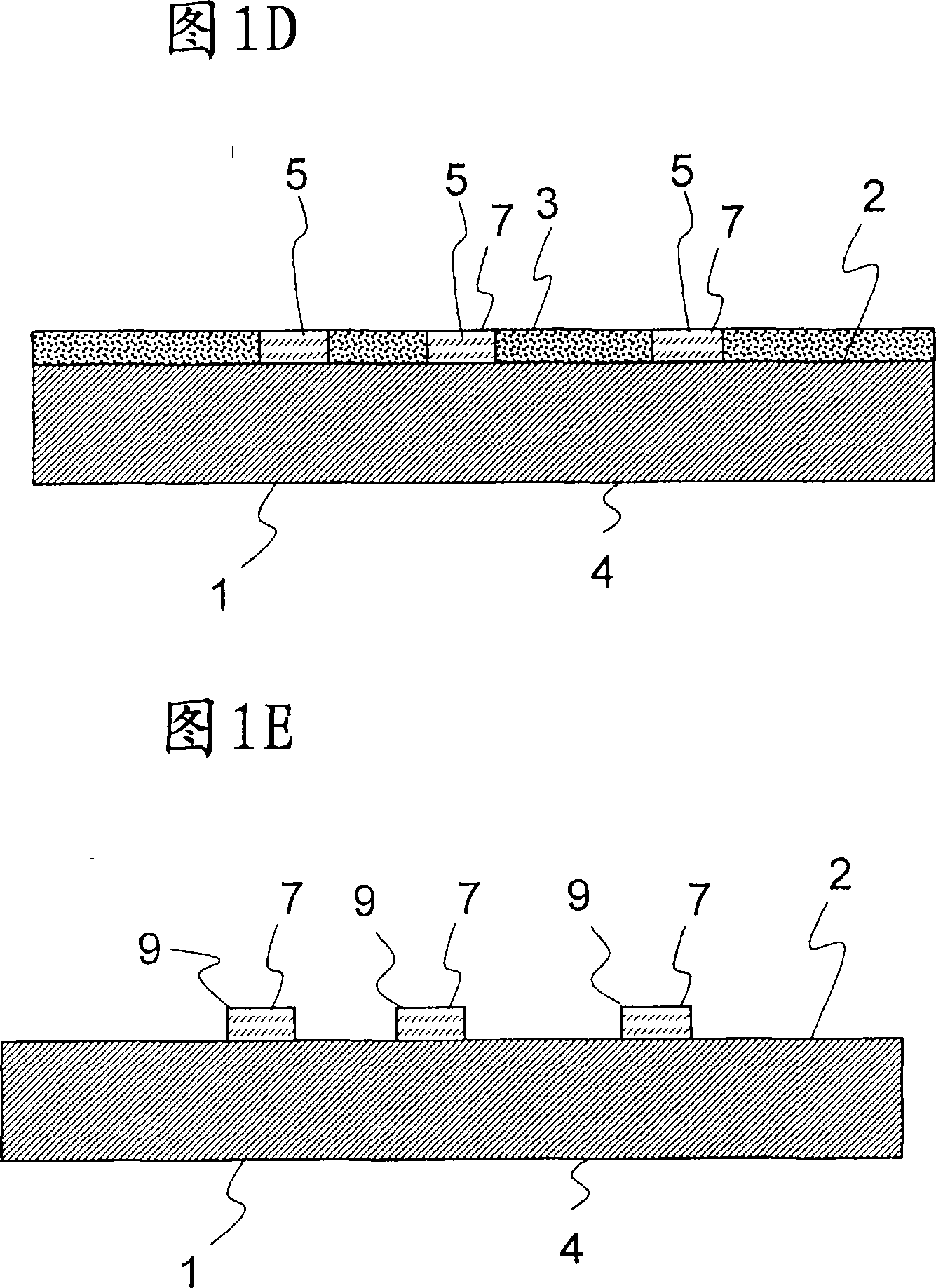

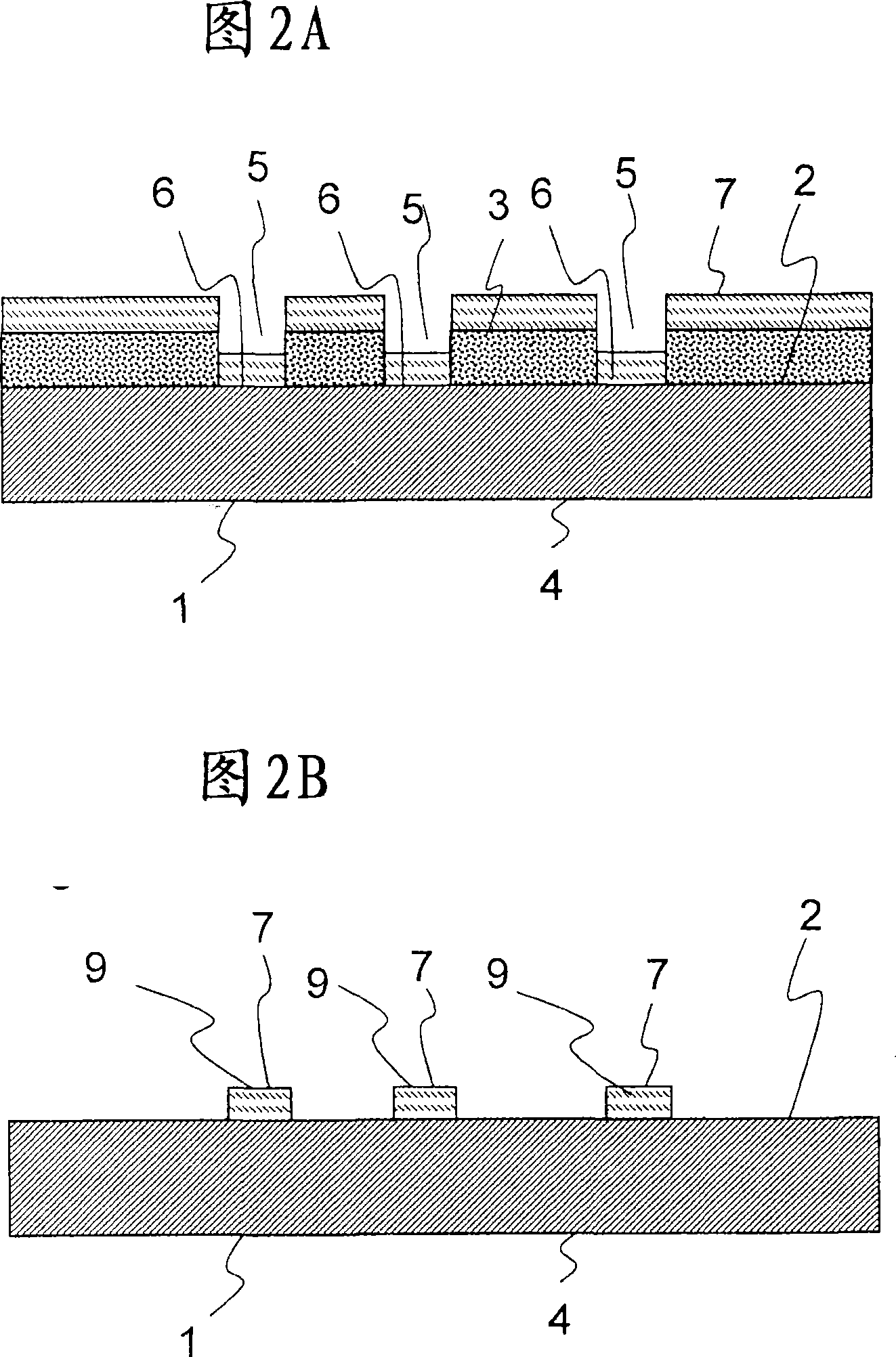

[0067] The following first discusses Figures 1A to 1E, which illustrate, by way of cross-sectional views, the process steps involved in fabricating a structured substrate according to a first embodiment of the present invention. To produce a structured coating, first a first coating 3 is applied to the surface 2 of the substrate 1 to be coated, as shown in FIG. 1A . Preferably, substrate 1 is connected to other substrates in the die pack. Preferably, the first coating layer 3 is formed of a photoresist layer. The substrate comprises at least one material selected from the group consisting of glass, ceramics, semiconductor materials, especially silicon, semiconductor compounds, metals, metal alloys, plastics, or combinations thereof.

[0068] Figure 1B shows a cross-sectional view of the substrate after another process step. In this step, structuring has been introduced into the first coating 3 . These structurings result in a negative structuring 5 which in plan view is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com