Electrooptical device and electronic apparatus

a technology of electronic equipment and optical components, applied in the field of optical components, can solve the problems of reducing the lifetime and display performance of the electrooptical device, difficult to provide a large-sized semiconductor sensor between the display region and the signal output circuit, and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Specific Configuration of Electrooptical Device 100

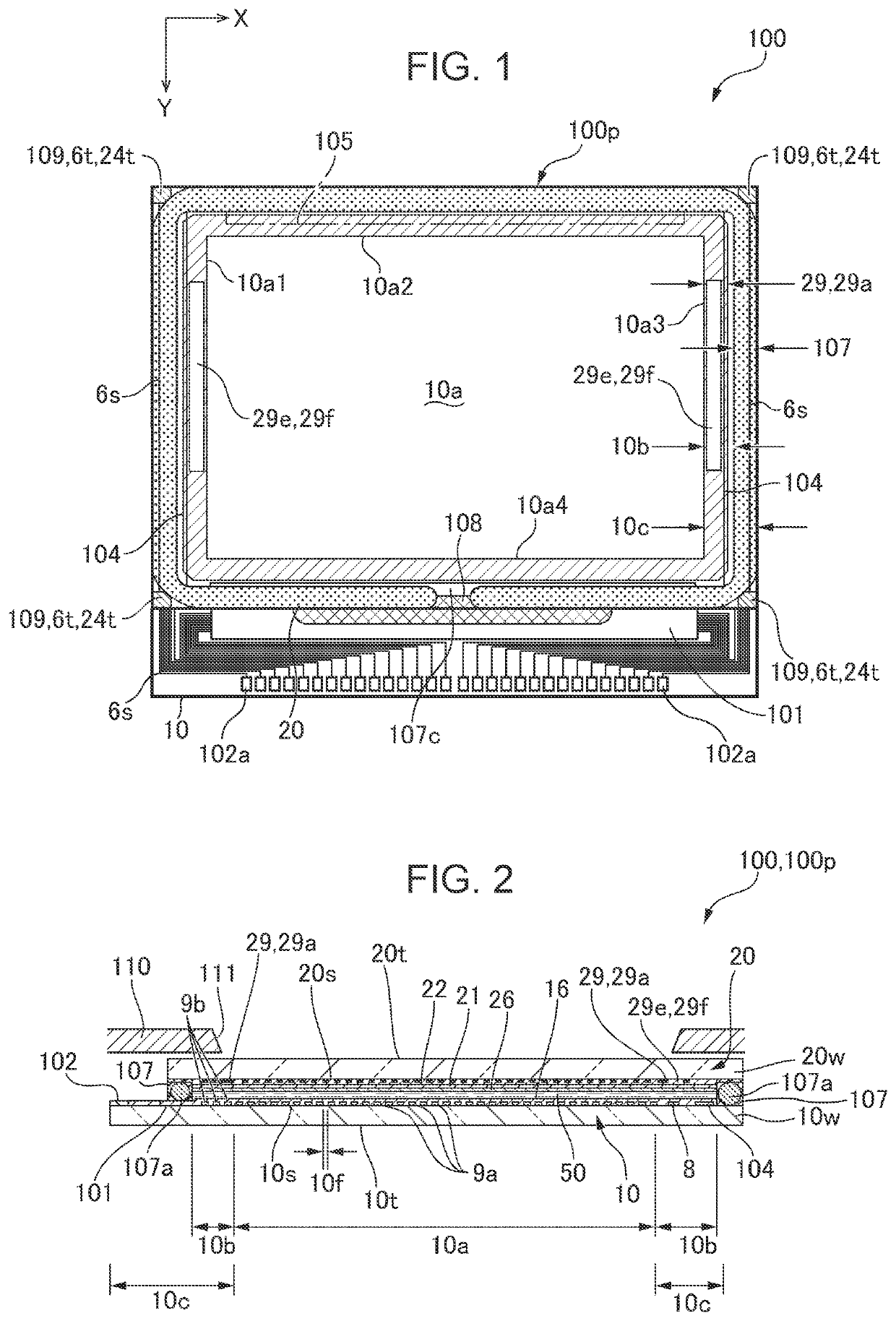

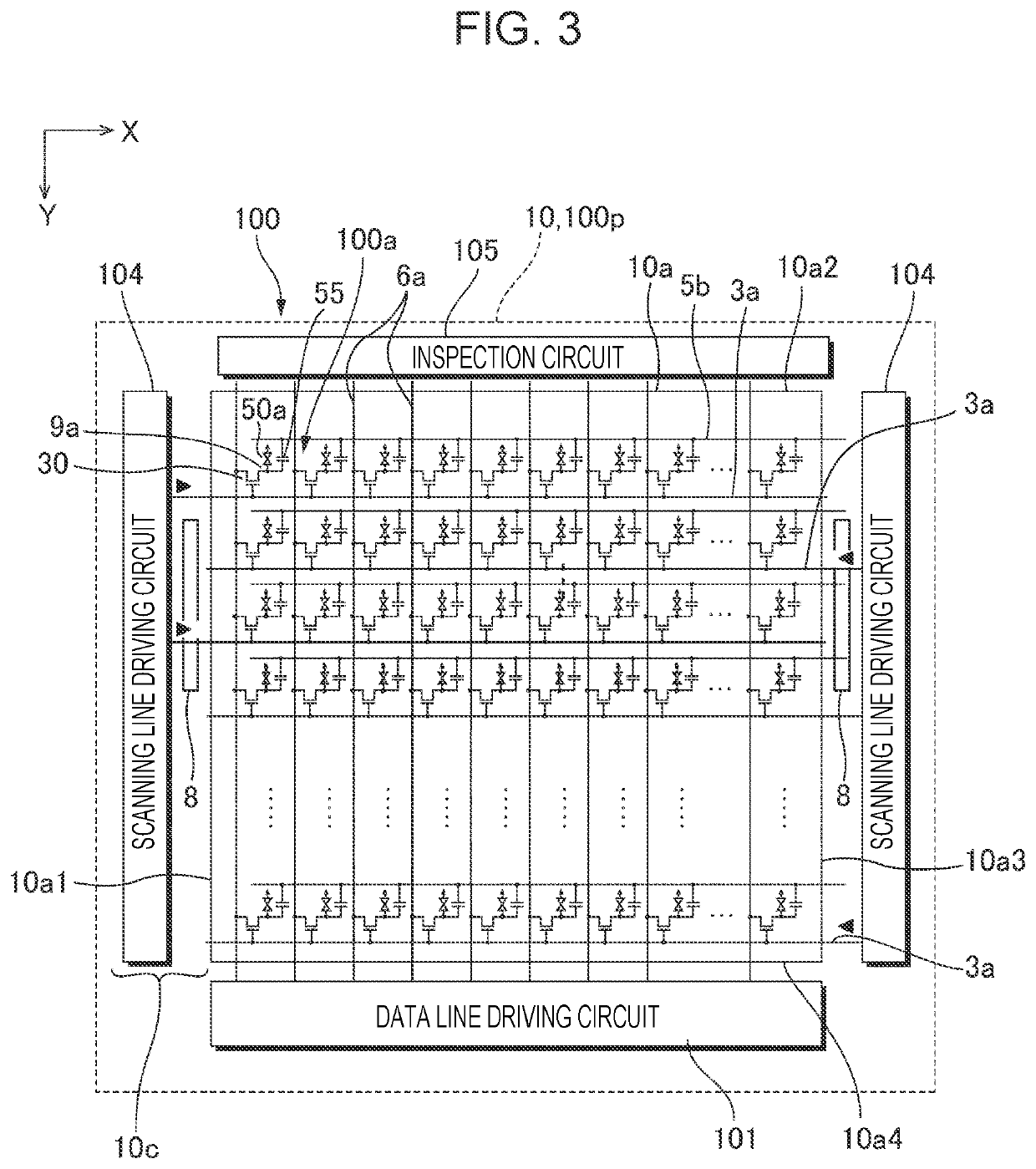

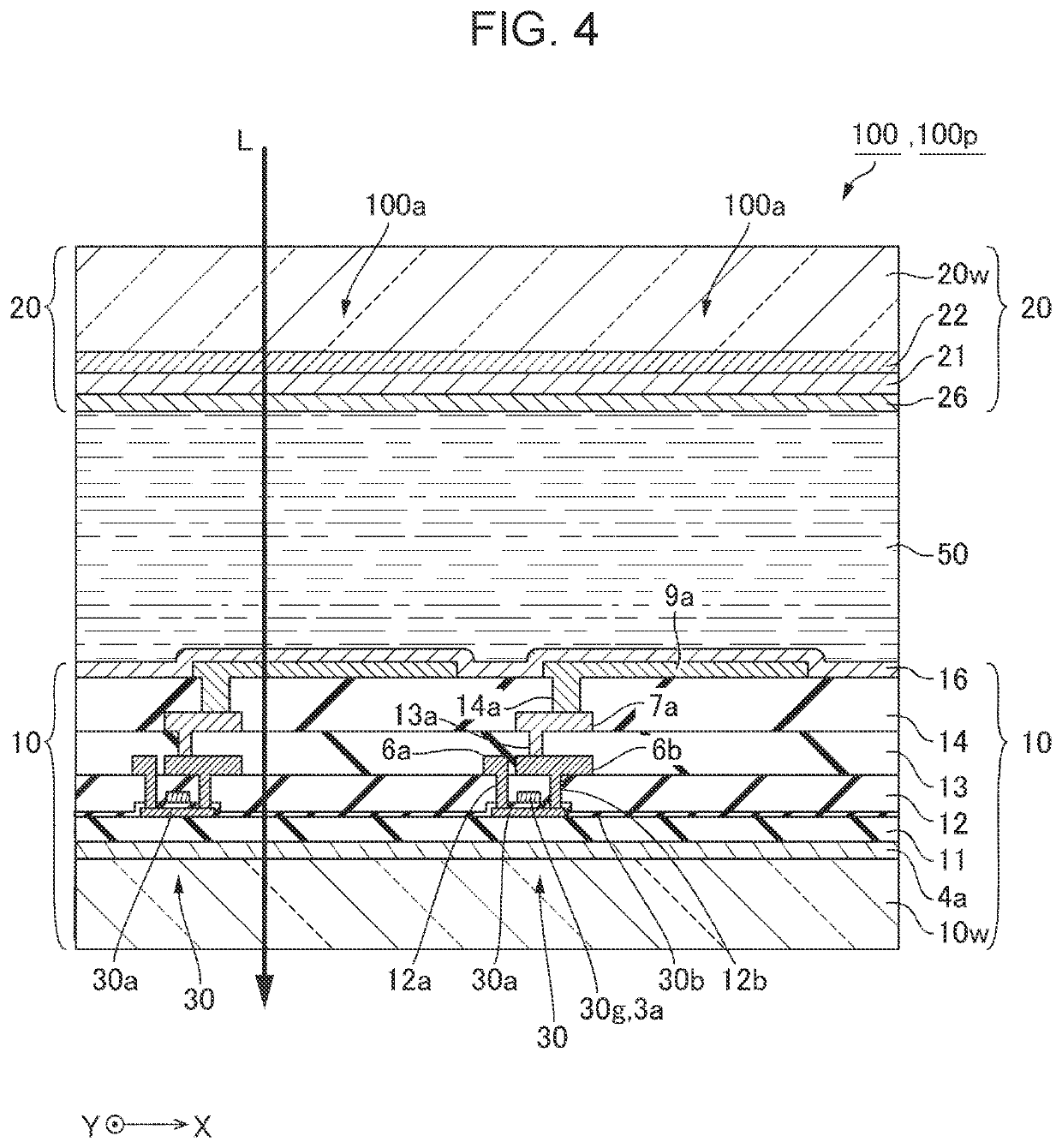

[0039]FIG. 1 is a plan view illustrating a configuration example of an electrooptical device 100 according to a first embodiment of the invention. FIG. 2 is an explanatory view schematically illustrating a section of the electrooptical device 100 illustrated in FIG. 1. The electrooptical device 100 illustrated in FIGS. 1 and 2 is a liquid crystal device, and includes a liquid crystal panel 100p. In the electrooptical device 100, a first substrate 10 and a second substrate 20 are bonded to each other by a sealing member 107 via a predetermined gap, and the sealing member 107 is provided in a frame shape along an outer edge of the second substrate 20. The sealing member 107 is an adhesive made of a photo-curable resin, a thermosetting resin, or the like, and a gap material 107a such as a glass fiber or a glass bead for keeping a distance between both substrates to a predetermined value is blended into the sealing member 107. In the li...

second embodiment

[0068]FIG. 10 is an explanatory diagram schematically illustrating a planar configuration of the semiconductor sensor 8 formed in the electrooptical device 100 according to a second embodiment of the invention. The basic configuration of the present embodiment and embodiments to be described is the same as that of the first embodiment. Thus, common portions are denoted by the same reference numerals, and a detailed description thereof will be omitted.

[0069]In the first embodiment, although the six diode elements 8b are connected to each other in series, as illustrated in FIG. 10, in the semiconductor sensor 8 (diode temperature sensor 8a) according to the present embodiment, five diode elements 8b are connected to each other in series. In addition, the scanning lines 3a linearly extend in the first direction X between the scanning line driving circuit 104 and the first side 10a1 of the display region 10a, and the sensor semiconductor layer 30s is formed between the scanning lines 3a...

third embodiment

[0070]FIG. 11 is an explanatory diagram schematically illustrating a planar configuration of the semiconductor sensor 8 formed in the electrooptical device 100 according to a third embodiment of the invention. As illustrated in FIG. 11, in the semiconductor sensor 8 (diode temperature sensor 8a) according to the present embodiment, three diode elements 8b are connected to each other in series. In addition, in a region between the scanning line driving circuit 104 and the first side 10a1 of the display region 10a, a part of the scanning line 3a is bent in the second direction Y, and then is linearly extended toward the display region 10a. In the present embodiment, the plurality of diode elements 8b are provided at a pitch of twice the wiring pitch Pa of the plurality of scanning lines 3a extending between the scanning line driving circuit 104 and the first side 10a1 of the display region 10a. Even in this case, a portion of the scanning line 3a is bent in the second direction Y, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrooptical | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com