Devices for surface finishing of parts

a technology for parts and surfaces, applied in the direction of grinding machines, edge grinding machines, manufacturing tools, etc., can solve the problems of lengthening working times, achieve the effect of avoiding negative effects on the working process, limiting adhesions during the working step, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

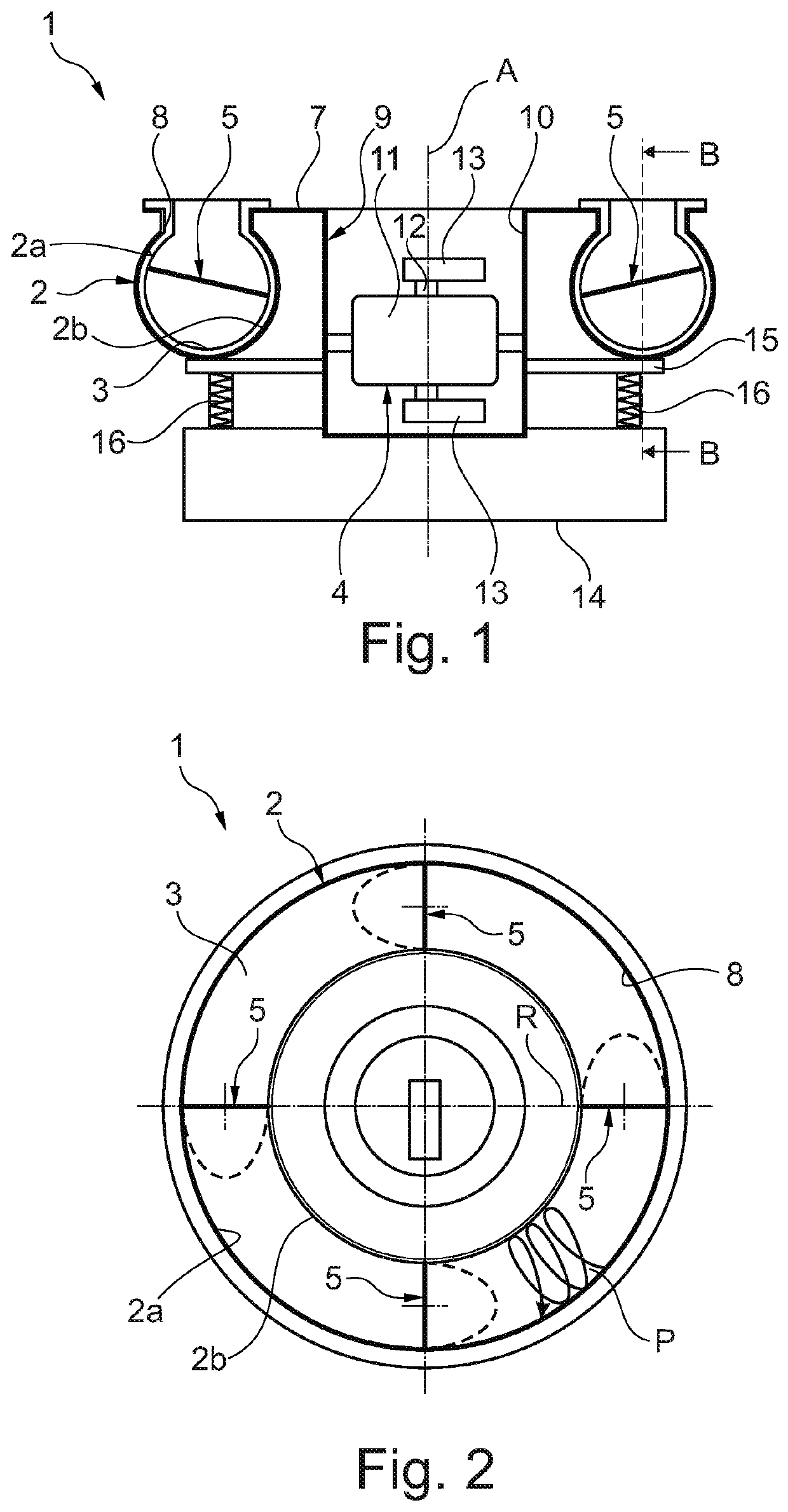

[0025]Referring to the enclosed figures, a device for surface finishing of parts according to the present invention is indicated by 1.

[0026]Referring in particular to FIG. 1, the device 1 comprises a base 14, adapted to be laid on and / or fixed to a fixed external surface, for example a floor. A movable platform 15 is arranged on the base 14, in particular it is linked thereto by means of a plurality of elastic shock absorbers 16. Such shock absorbers 16 are made in a way known to the person skilled in the art, and comprise for instance some springs.

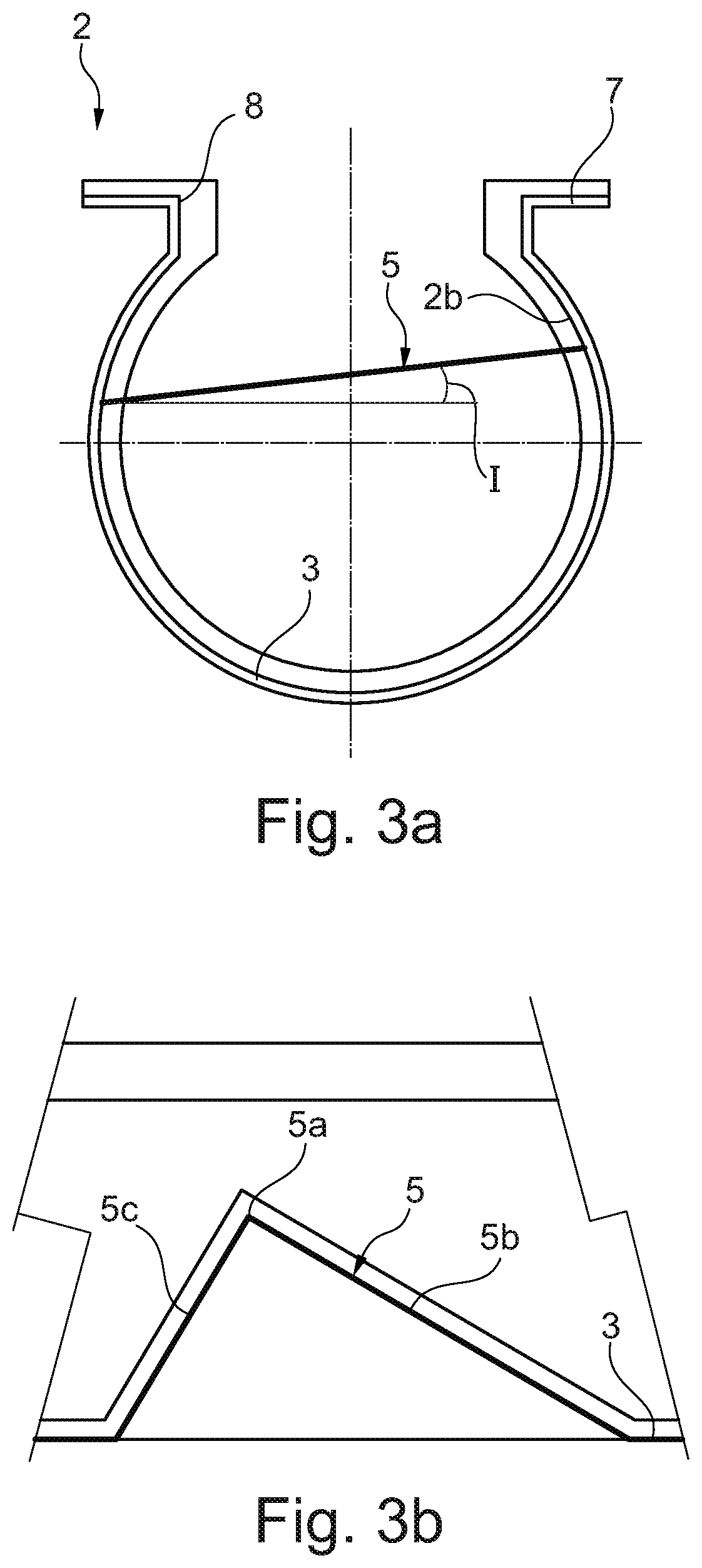

[0027]The device 1 comprises an annular container 2, having a central axis “A” and a bottom surface 3. In particular, the container 2 is fixed to the above-mentioned movable platform 15. Such container 2 is adapted to receive one or more parts to be treated. To this end, the container 2 is configured to receive a plurality of working media. In the background of the present invention, “medium” means a solid element adapted to react with ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com