Apparatus and method for manufacturing a semiconductor package

a semiconductor and packaging technology, applied in the field of apparatus and method for manufacturing flipchip semiconductor packages, can solve the problems of reducing difficulty in completely filling the gap between the semiconductor reducing the rate at which the resin enters the gap between the chip and the mount board, so as to improve the grade and quality of the semiconductor devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

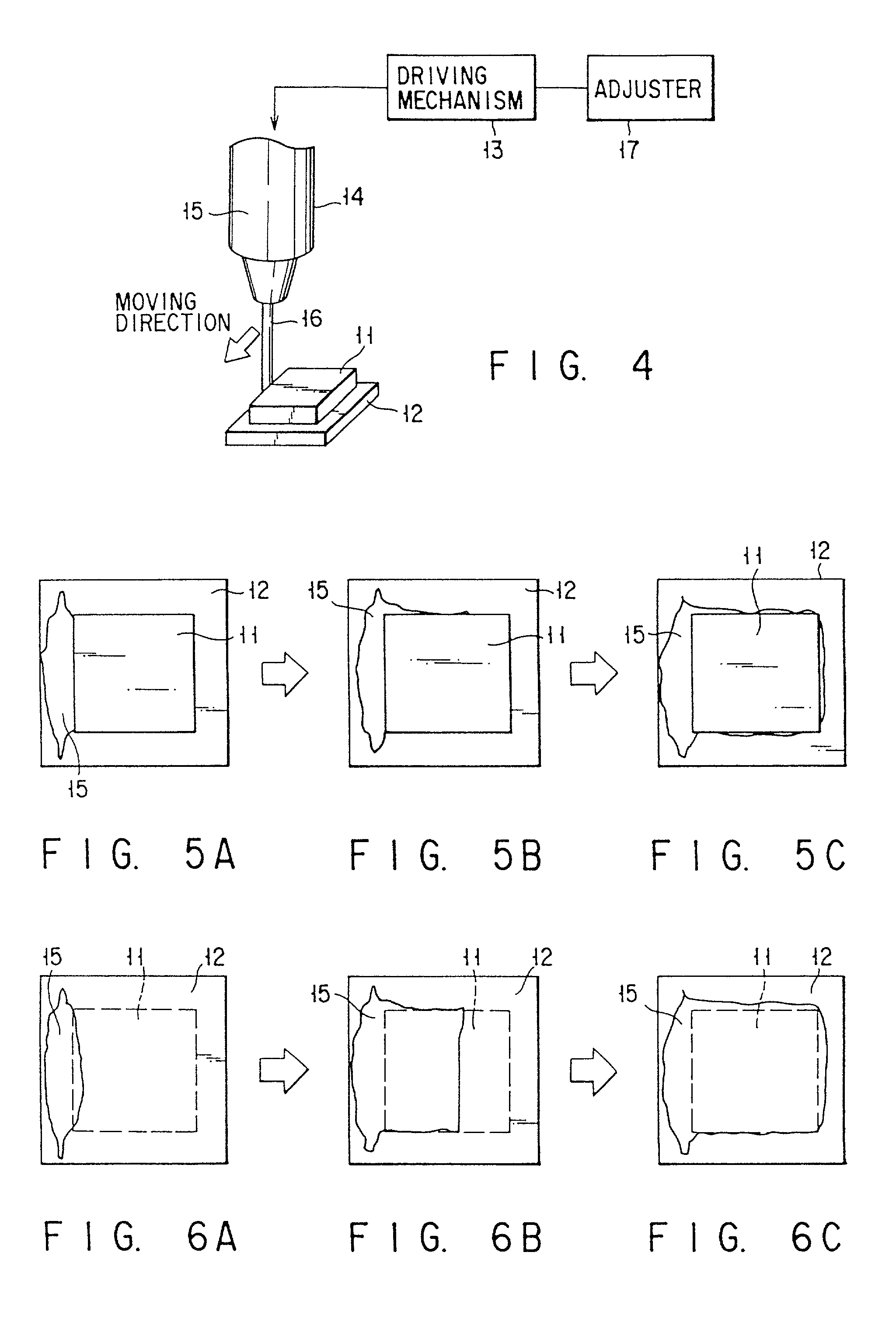

23. FIG. 4 shows a method for manufacturing a semiconductor package according to the present invention. A semiconductor chip 11 is mounted on a mount board 12 by a flip-chip connection, and then a driving mechanism 13 moves a syringe 14 along one side of the semiconductor chip (in the direction indicated by the arrow in the figure). In more detail, the semiconductor chip 11 is provided with electrode pads that are arranged along the periphery of the chip. Wiring pads are arranged on the surface of the mount board 12 at positions corresponding to the electrode pads of the semiconductor chip 11, and are connected to the electrode pads via metal bumps (e.g., solder bumps). The wiring pads are led out of the bottom surface of the mount board 12 via through-holes and are connected to external pads that are arranged, for example, in a matrix on the reverse surface of the mount board. The mount board is typically formed with materials such as epoxy resin, alumina (Al.sub.2O.sub.3), aluminu...

fifth embodiment

36. Similar to the fifth embodiment, the viscosity of the resin flowing through the gap is partially varied by controlling the temperature distribution of the mount board so that the portions of the mount board corresponding to the end portions of the semiconductor chip are at a lower temperature than the portion of the mount board corresponding to a central portion of the chip. Thus, as the resin is supplied to the mount board (e.g., by a multi-nozzle 65 having a nozzle support body 63 and nozzles 64 with the same diameter), the viscosity of the resin near the central portion of the chip is reduced so that the rate at which the resin flows through the gap near the central portion of the chip is higher than the rate at which the resin flows near the peripheral portions of the chip (see equations 1 and 2). Accordingly, the heater block and adjacent radiator plates allow the resin to completely fill the gap so that a high-grade, high-quality semiconductor device is produced.

37. In the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com