Packaging and dispensing device including a vacuum-filled container, and a method of manufacture

a technology of packaging and dispensing device and vacuum-filled container, which is applied in the direction of liquid handling, packaged goods type, instruments, etc., can solve the problems of device complexity, deformation of the discharge channel of the dispenser endpiece, and deformation of the discharge channel, so as to increase the number of ways in which the pump can be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

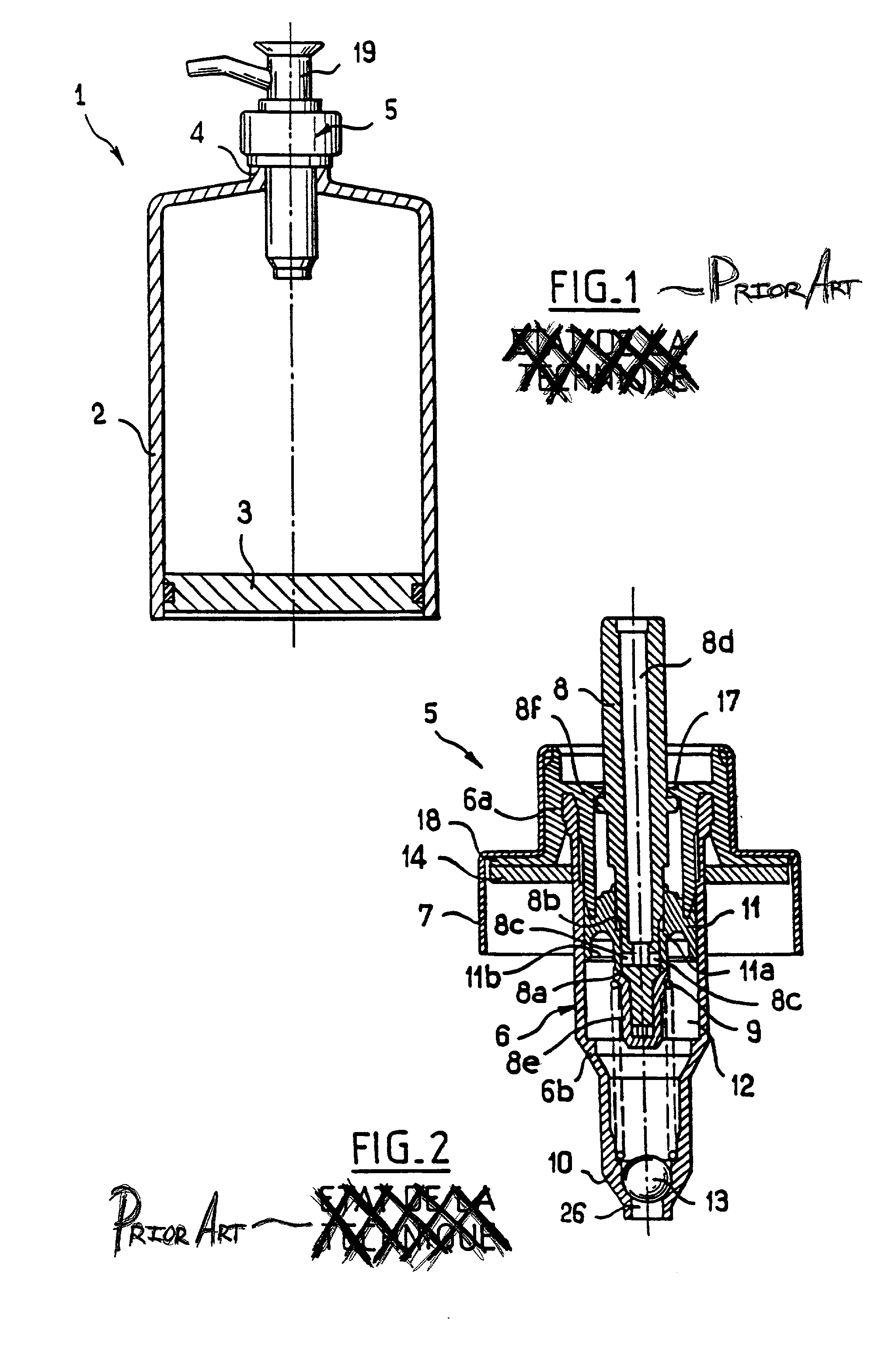

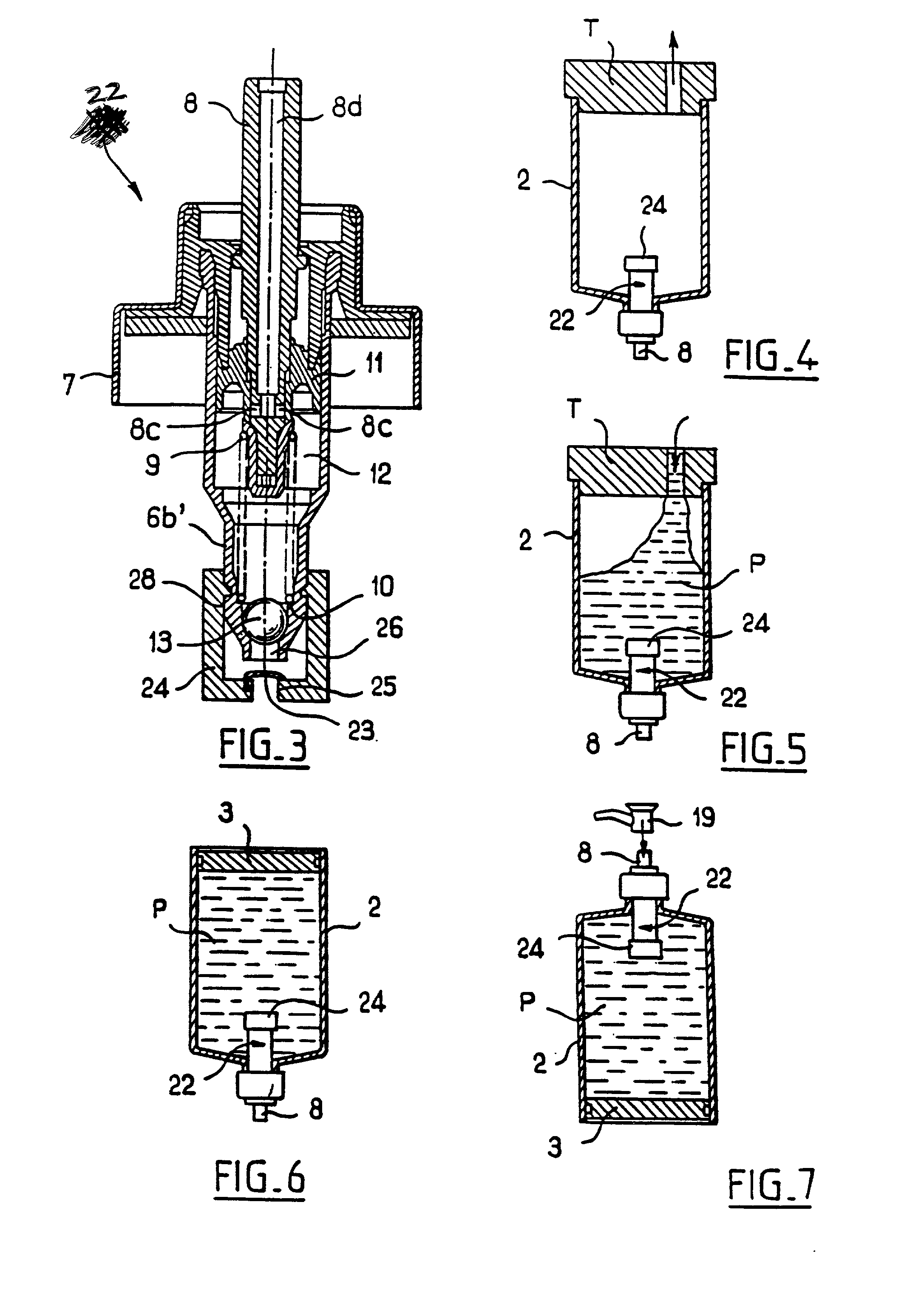

[0049] FIG. 1 shows a prior art packaging and dispensing device 1.

[0050] The device 1 comprises a container constituted by a cylindrical-walled container 2 fitted with a moving bottom constituted by a piston 3 that slides in sealed manner inside the wall 2.

[0051] The container 2 has a neck 4 at its top end on which there is fixed a pump 5 which is shown in section in FIG. 2.

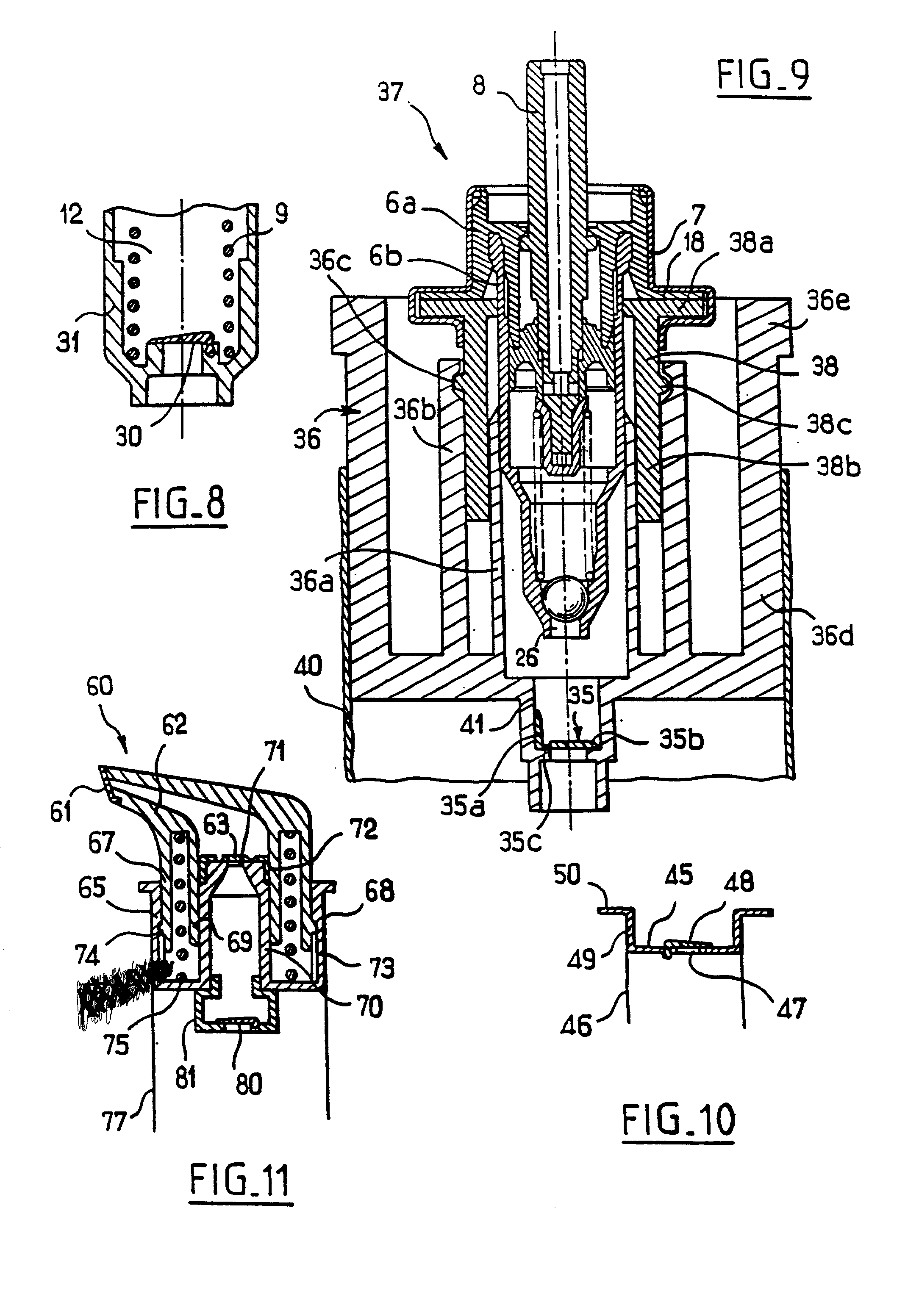

[0052] The pump 5 comprises a pump body 6 constituted by snap-fastening together a top portion 6a and a bottom portion 6b.

[0053] A control rod 8 is mounted so that its bottom portion slides inside the body 6 against the action of a return spring 9 that operates in compression, one end of the spring 9 bearing against a shoulder 10 at the bottom of the bottom portion 6b of the body 6, and its other end bearing against a shoulder 8a on an endpiece 8b fixed to the bottom end of the control rod 8.

[0054] The top portion 6a has a flange 18 serving to mount the pump 5 together with a sealing ring 14 situated beneath the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| vacuum | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com