Dryer-ironer with heated ironing cup and heat carrying fluid

a technology of ironing cup and heat carrying fluid, which is applied in the direction of ironing apparatus, washing machine, textiles and paper, etc., can solve the problems of heavy weight, expensive external facilities, and inability to carry heavy objects,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

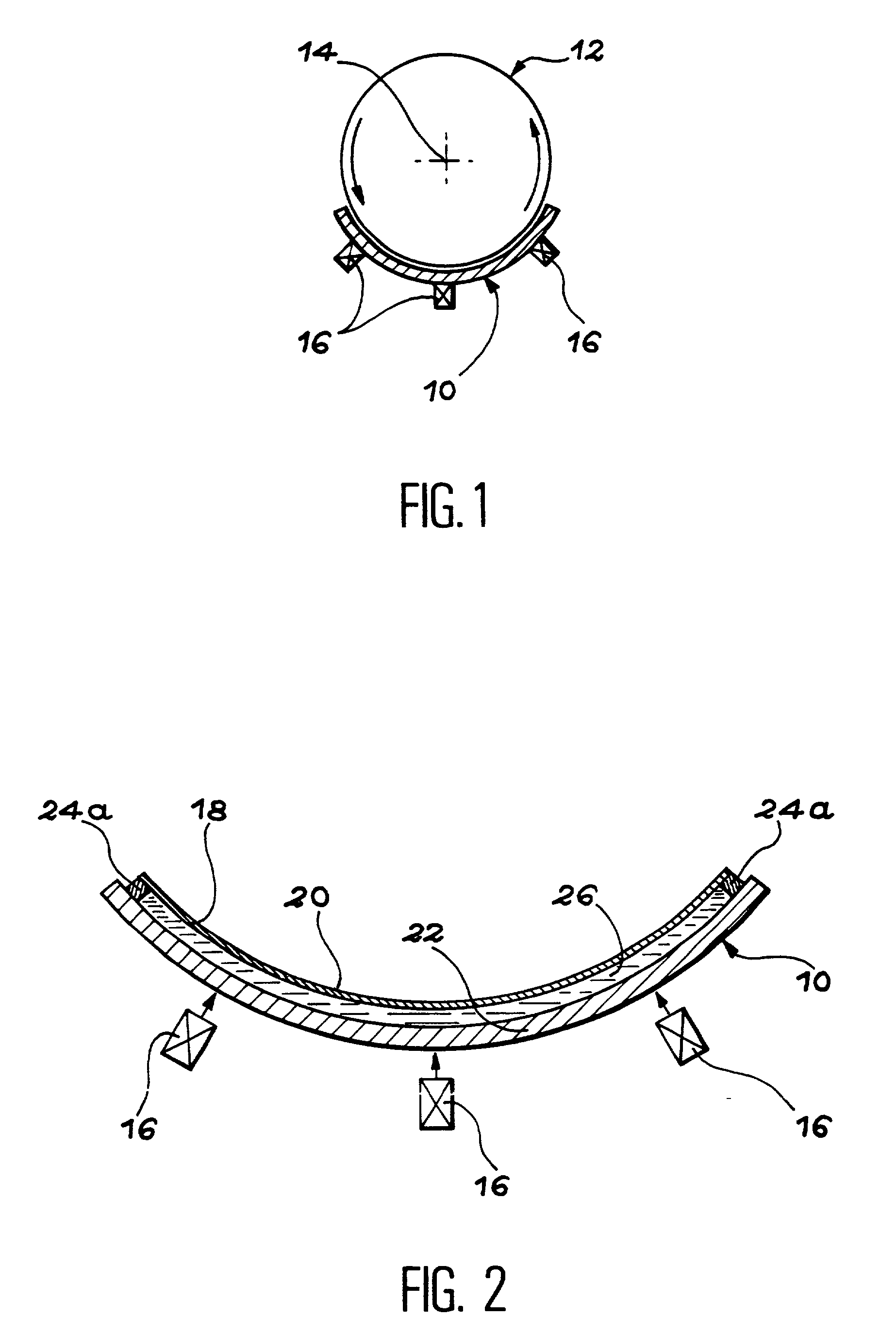

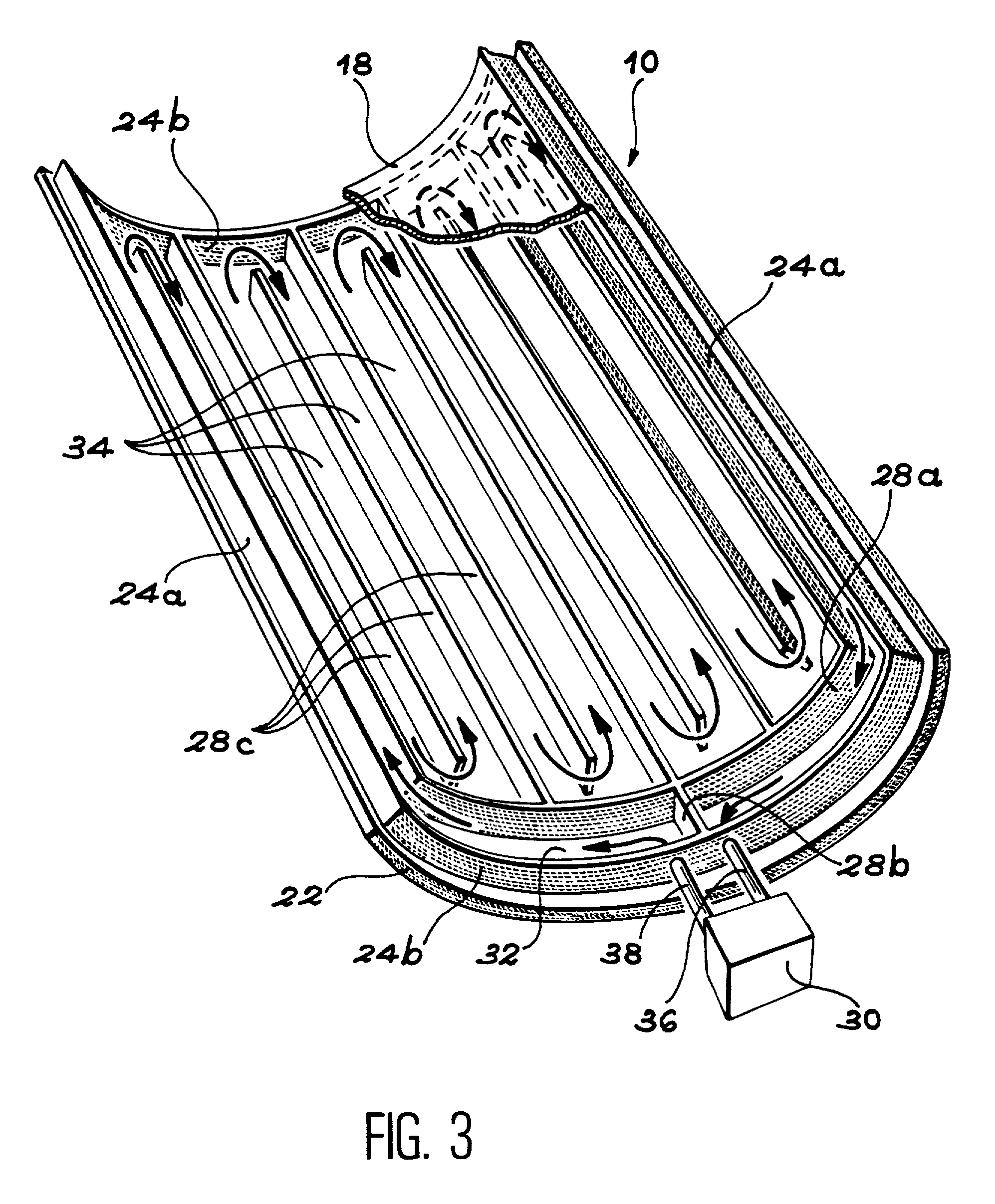

[0012] Specifically, the object of the invention is a dryer-ironer with heated cup, its original design allows it to benefit both from cost effectiveness and cost advantages specific to machines with integrated heating and from the advantages provided by uniform diffusion of heat on the entire length of the cup of machines which are heated through a heat carrying fluid.

[0013] According to the invention, this result is obtained by means of a dryer-ironer comprising an ironing cup in the shape of a cylindrical sector provided with an internal wall, able to come into contact with the laundry to be ironed, and means for heating said wall, characterized in that the cup further comprises an external wall which externally lines, at a distance, the internal wall, directly close to the heating means, so as to delimit with said internal wall, a closed chamber filled with a heat carrying fluid able to transfer heat produced by heating means to the internal wall, and stirring means able to gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com