Gas flow control device

a flow control and gas technology, applied in the direction of sealing/packing, instruments, borehole/well accessories, etc., can solve the problems of difficult to calculate the flow rate of gas past the valve, complicating any design or examination, and reducing the unsuitable effect, so as to reduce the unsuitable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

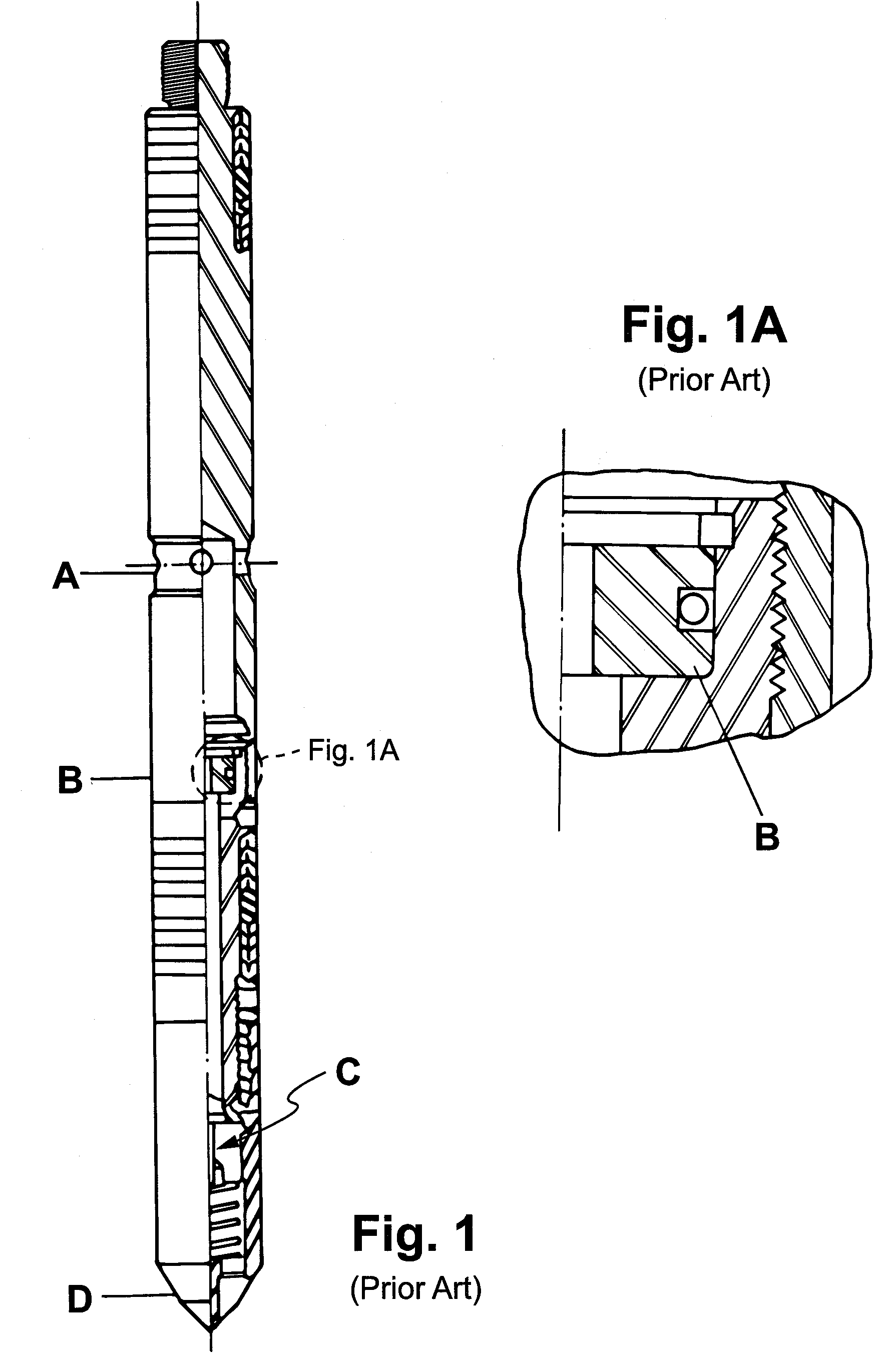

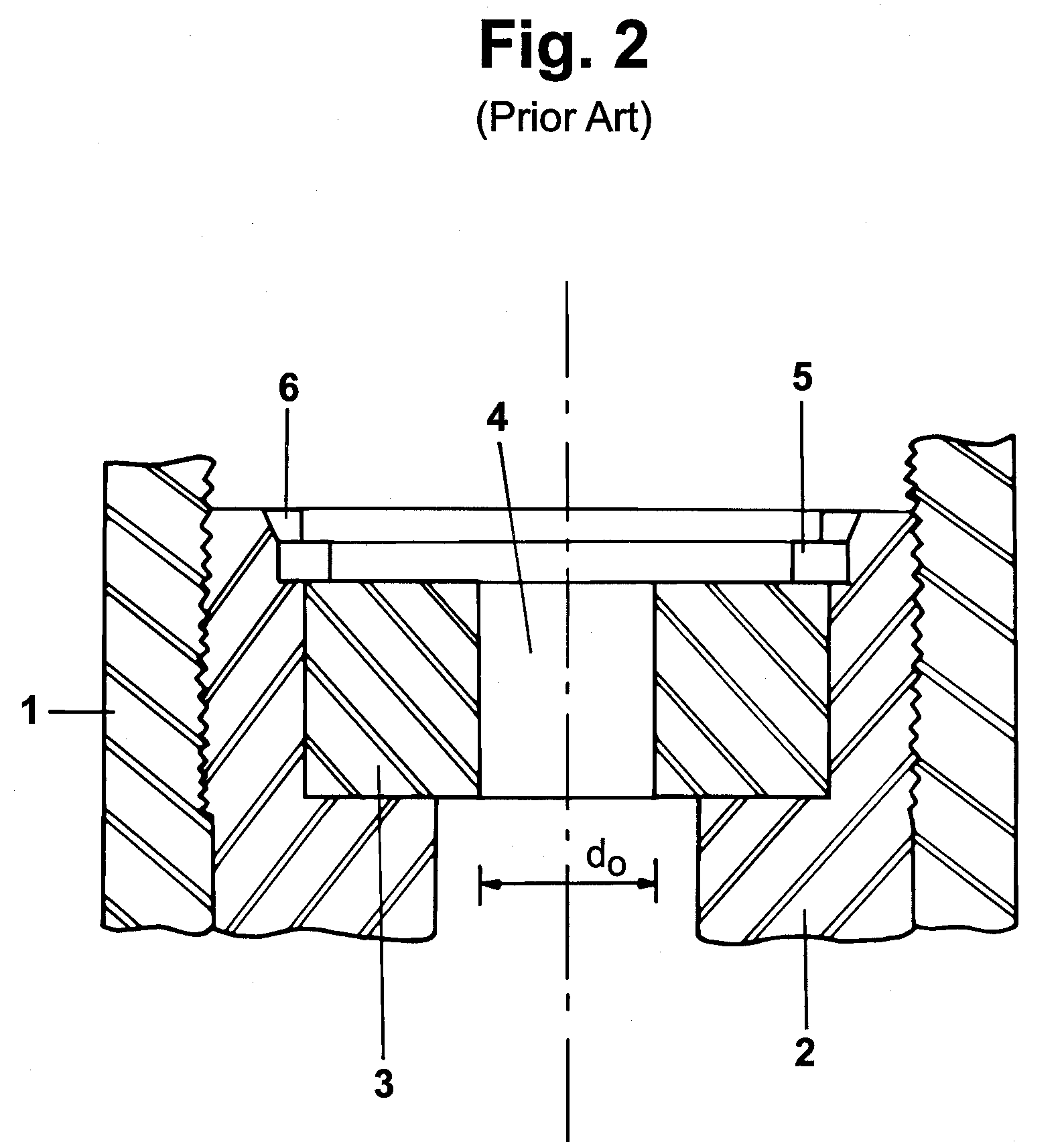

[0013] Figure 1 is a sketch of a gate valve type of gas-lift valve currently in use. In the Figure there is a point marked A where gas enters the valve, passes through the valve seat B (that is, the gate), passes check valve C and leaves out of nose D for the inside of the pipe, Figure 1 also shows a detailed view in section of the seat, shown as a sketch in Figure 2, in which the cylindrical body of valve 1 can be seen, the housing 2 for the seat, and the seat 3, the gate 4 and o ring 5.

[0014] It will be seen that seat 3 is just a disk in which a cylindrical hole of the wanted diameter has been drilled. Edges are, as a rule, sharp but they may also be slightly chamfered 6.

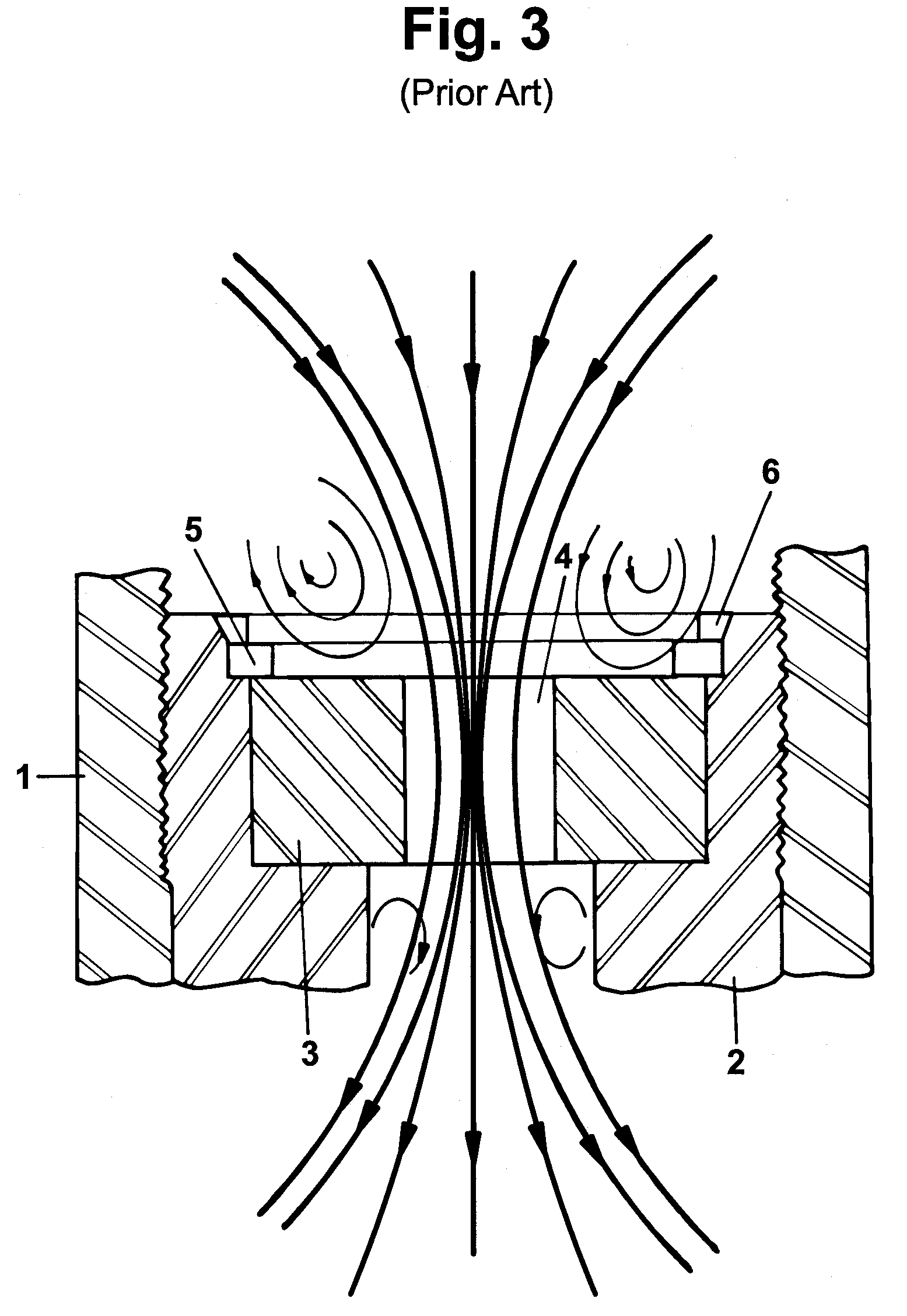

[0015] Figure 3 is a sketch of flow lines through the gate 4 as through seat 3. Sudden contracting and expanding causes swirls which bring about heavy load losses. Furthermore, the smallest area of flow does not take place along the the tight part (seat) but rather, further on, as a phenomenon known as "vena contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com