Drive system

a technology of drive system and drive shaft, which is applied in the direction of electric propulsion mounting, machine/engine, engine starter, etc., can solve the problems of affecting the functionality of electric motor, and achieve the effect of avoiding affecting the functionality of electric machines and transferring thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

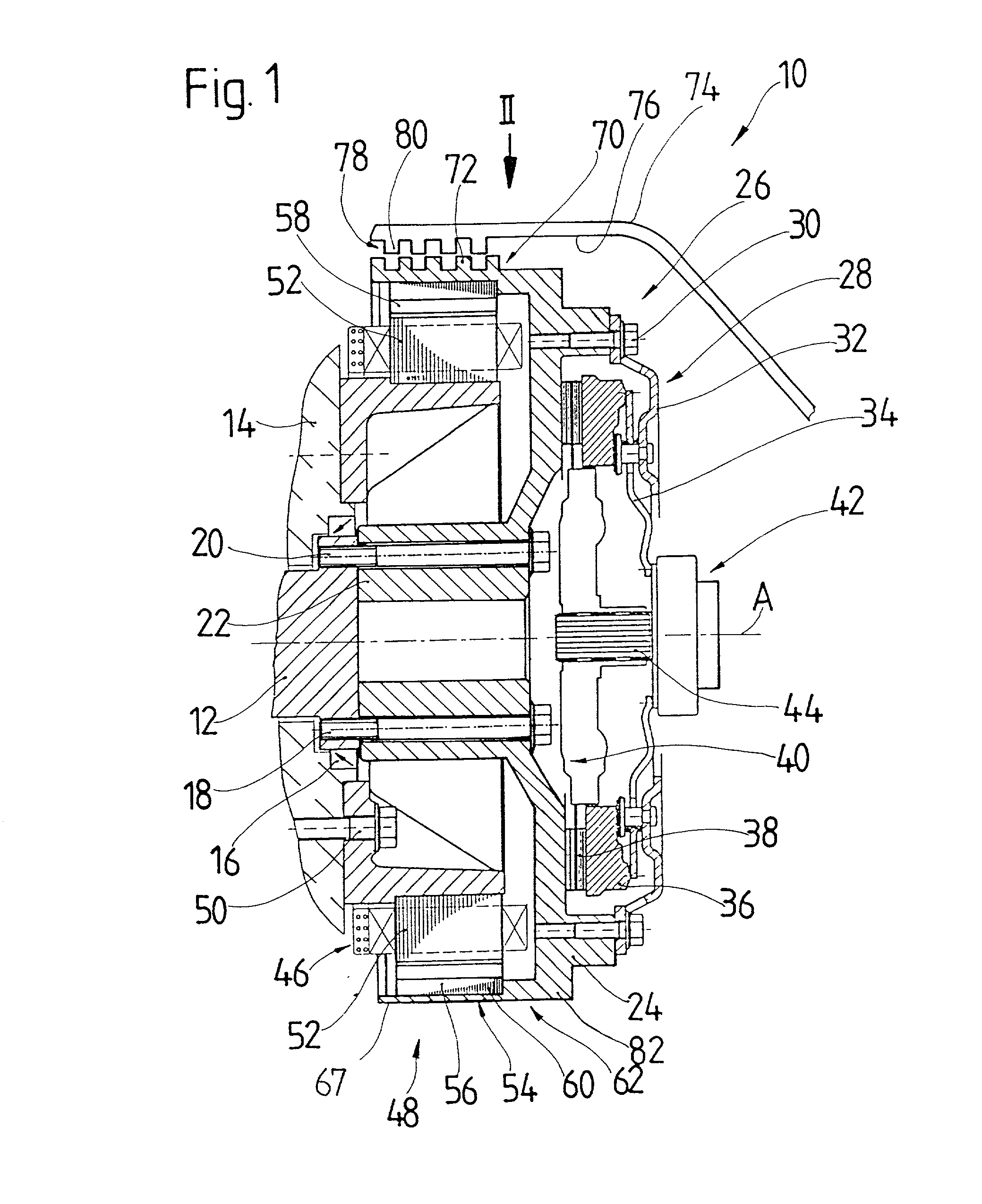

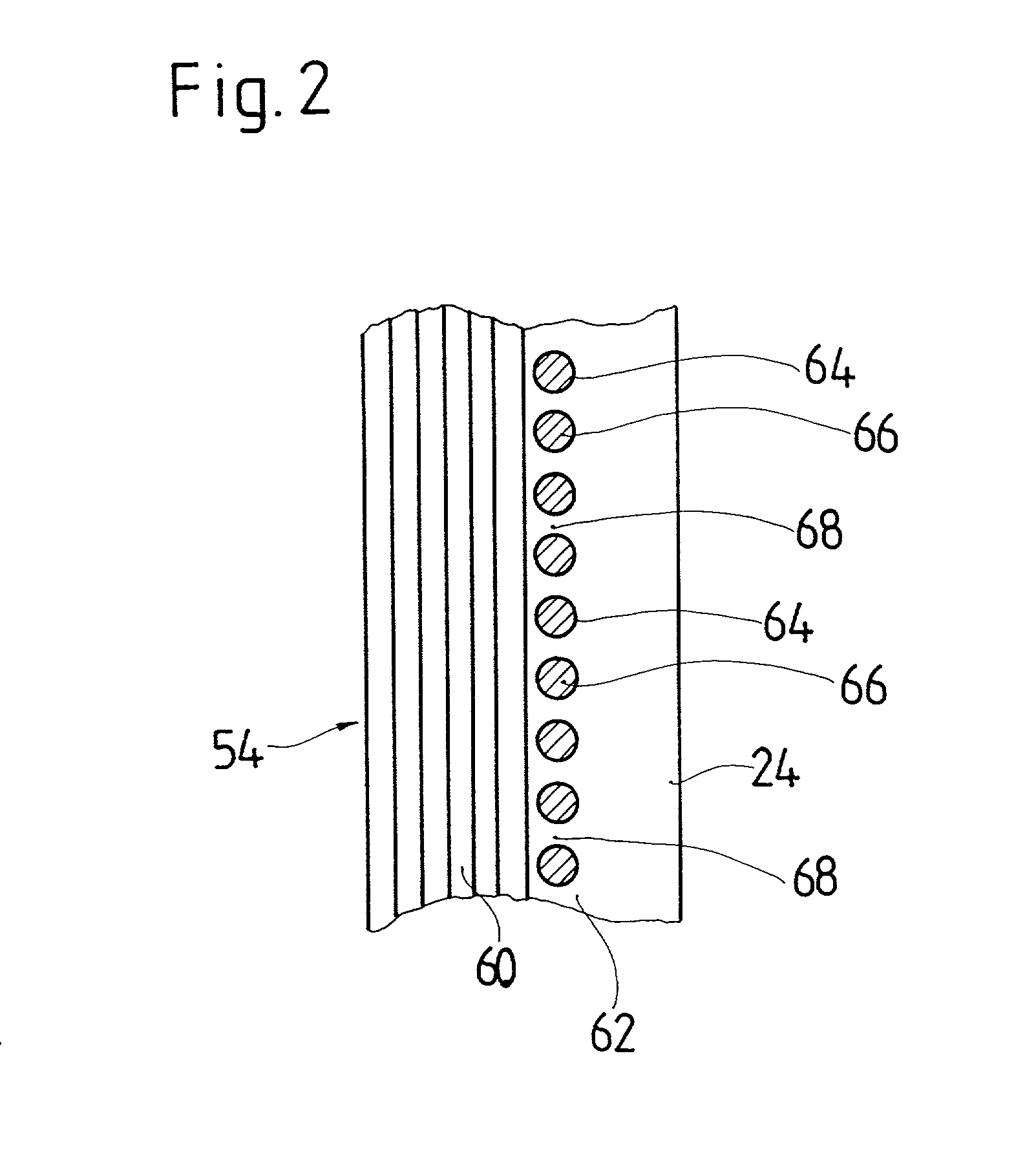

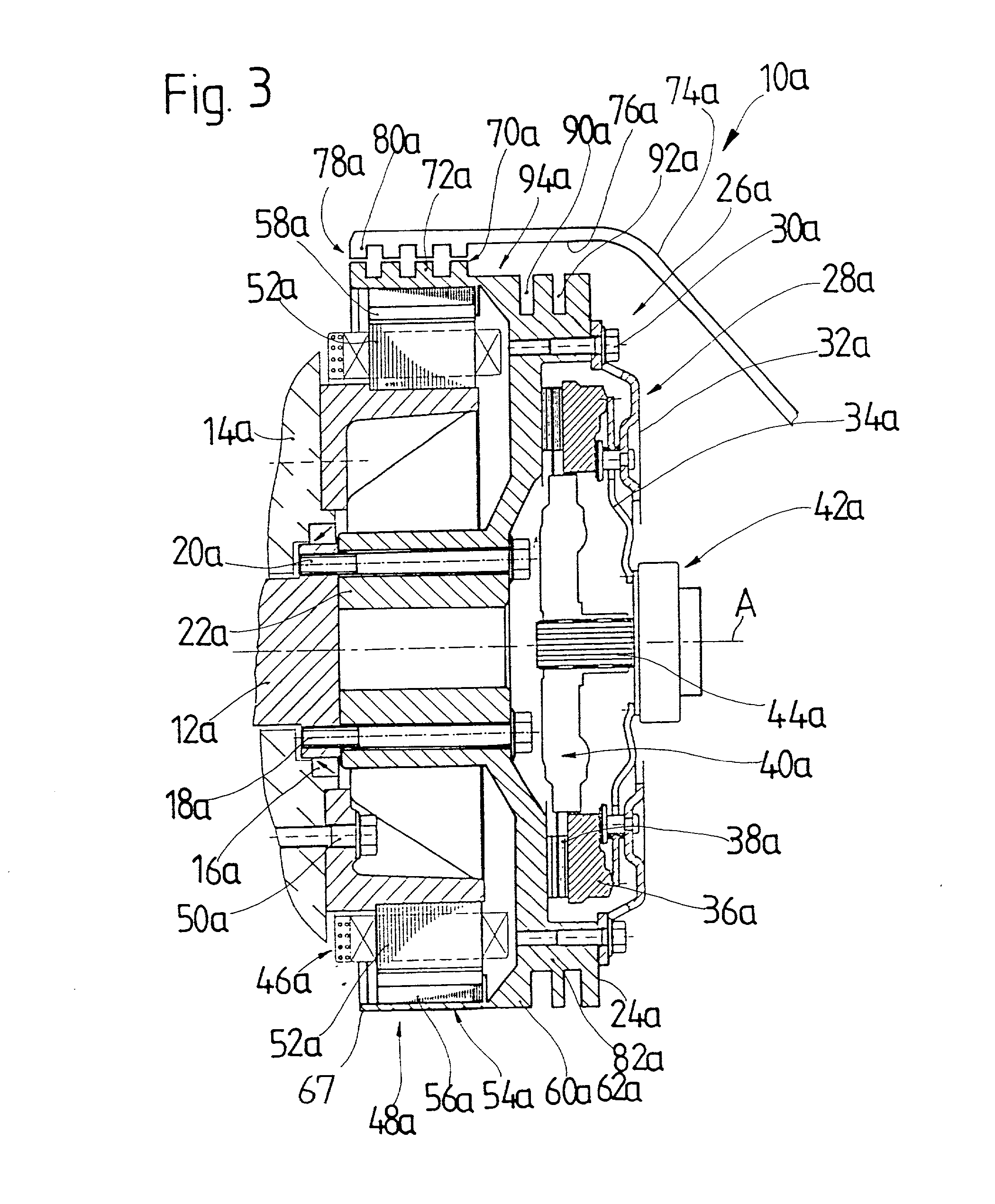

[0038] A drive system 10 according to an embodiment of the present invention is shown in FIG. 1. The drive system 10 comprises a drive shaft 12 which is rotatably mounted at the end in a crankcase 14 via a bearing 16. The drive shaft 12 may, for example, comprise a crankshaft of an internal combustion engine. A flywheel mass arrangement such as, for example, a flywheel 24 of a motor vehicle friction clutch 26 is connected in a rotationally secure fashion to a crankshaft flange 18 on the drive shaft 12 via a plurality of screw bolts 20 and a spacer element 22.

[0039] The motor vehicle friction clutch 26 comprises a pressure plate assembly 28 which includes a clutch housing 32 and a pressure plate 36 which is biased toward the flywheel 24 in the direction of an axis of rotation A under the biasing of an energy storage mechanism 34. A radially outer region of the clutch housing 32 is permanently connected by screw bolts 30 to the flywheel 24. The energy storage mechanism 34 may, for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com