Catalytic combustor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

[0037] [Embodiment]

[0038] Hereinafter, the catalytic combustor in accordance with the present invention will be explained in more detail based on several embodiments.

[0039] [Catalytic Combustor]

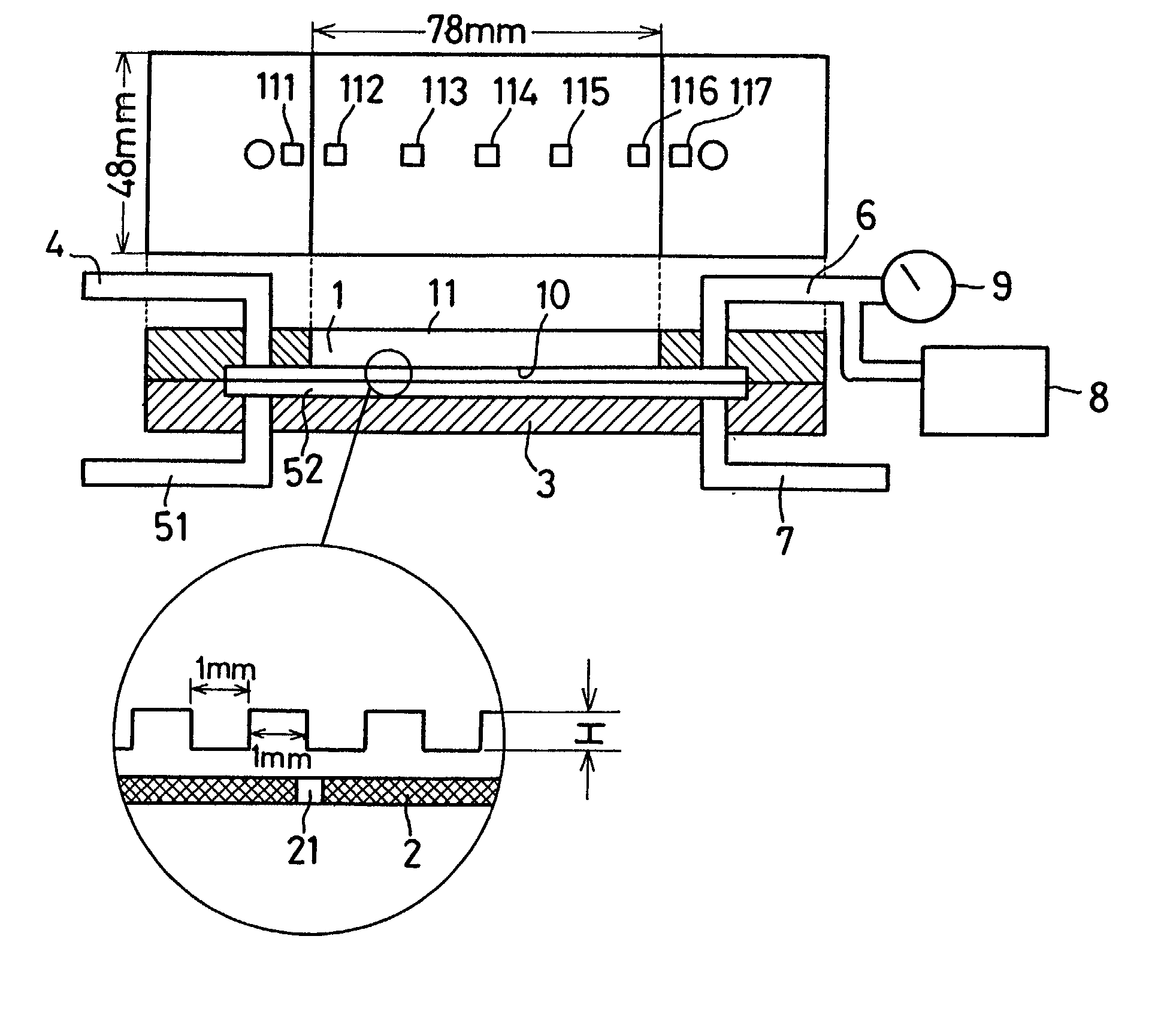

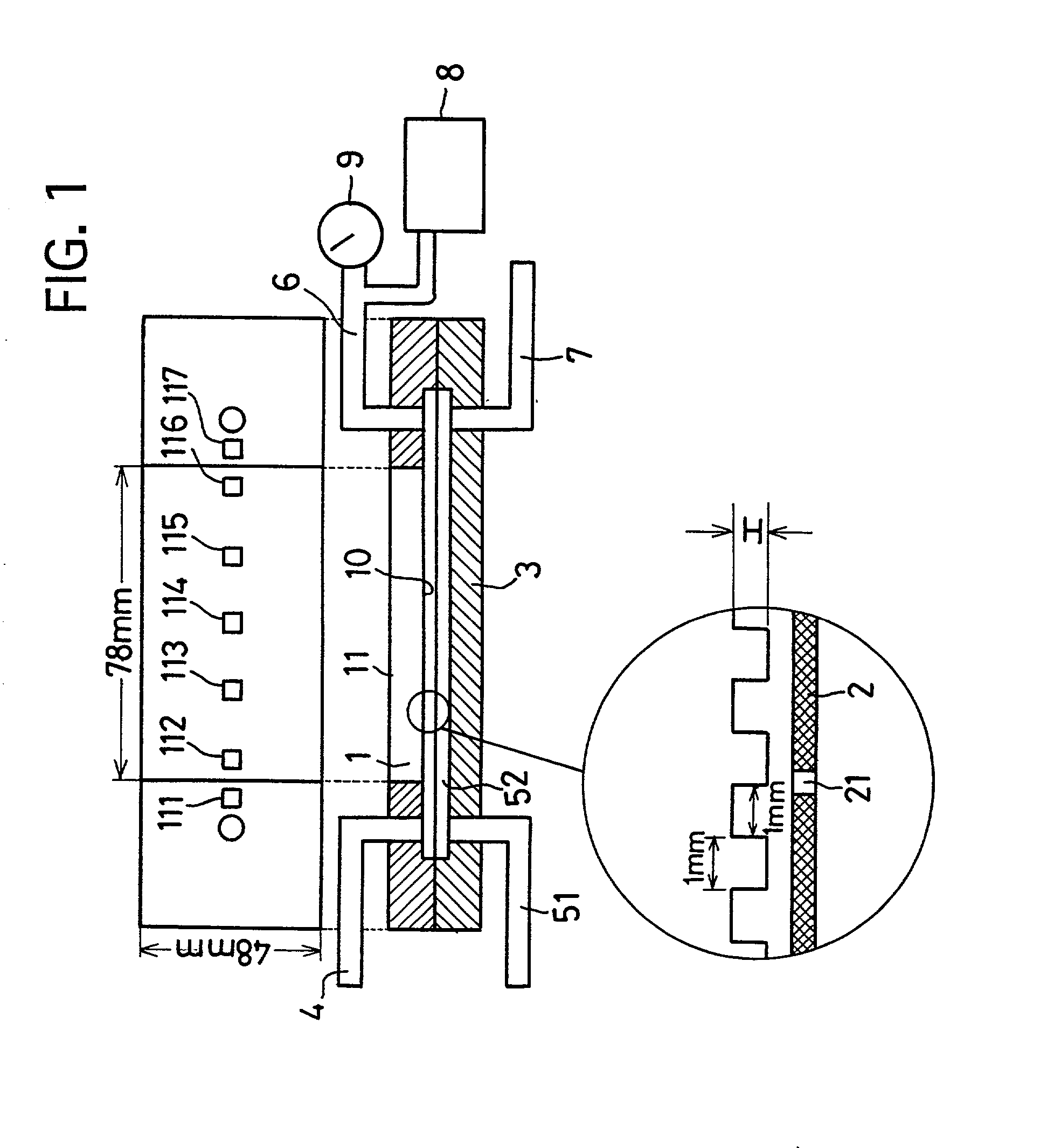

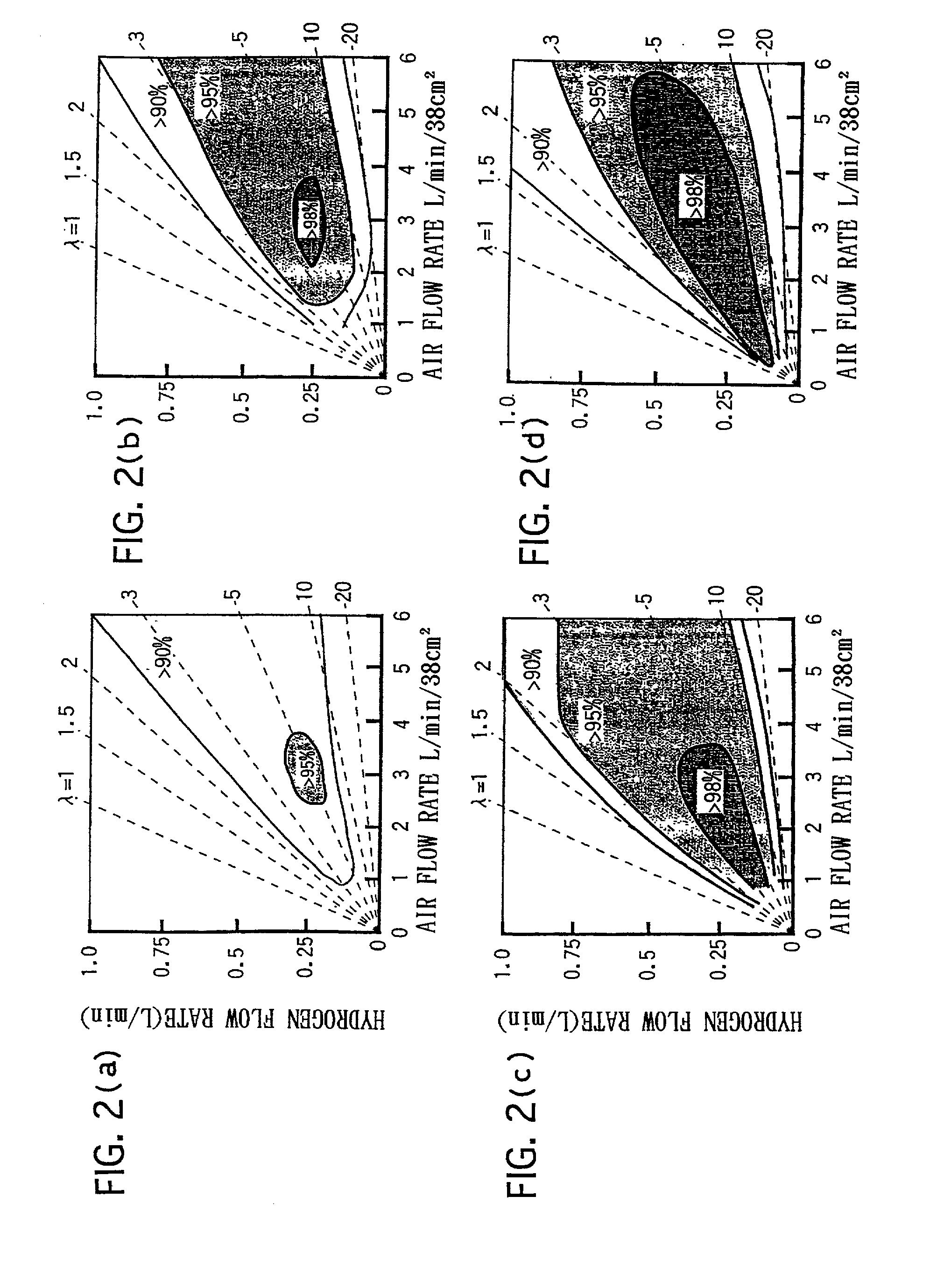

[0040] The catalytic combustor which was used in tests is schematically illustrated in FIG. 1. The catalytic combustor of the present embodiment includes a heat-conductive separator 1 which has projections and depressions in one part 10 (78 mm.times.49 mm) of a surface which faces a combustion chamber, a catalyst layer (not shown) which is supported on the part 10, a wall 2 which has supply ports 21 (opening diameter 0.3 mm, 12 ports) for supplying fuel toward the part 10, faces the heat-conductive separator 1, and defines the combustion chamber with the heat-conductive separator 1, a plate-like member 3 which is located to face the wall 2 on the opposite side of the combustion chamber and defines one part (52) of a fuel supply passage, an air supply passage 4 which is communicated with a sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com