Method for continuously monitoring chemical species and temperature in hot process gases

a technology applied in the field of continuous monitoring of chemical species and temperature in hot process gases, and continuously monitoring the concentration of reactants, can solve the problems of limiting the available monitoring methods to extractive sampling techniques, adding to the measurement delay, and slowing down the response time from approximately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Methods for monitoring important species in-situ in the gas phase with fast response times and high accuracy provides a means to regulate many industrial processes for maintaining optimum performance, where performance means global or local stoichiometry, gas temperature, particle density, and air entrainment estimates. Measuring and controlling these quantities provides a means for production quality control, pollutant reduction, and improved energy efficiency.

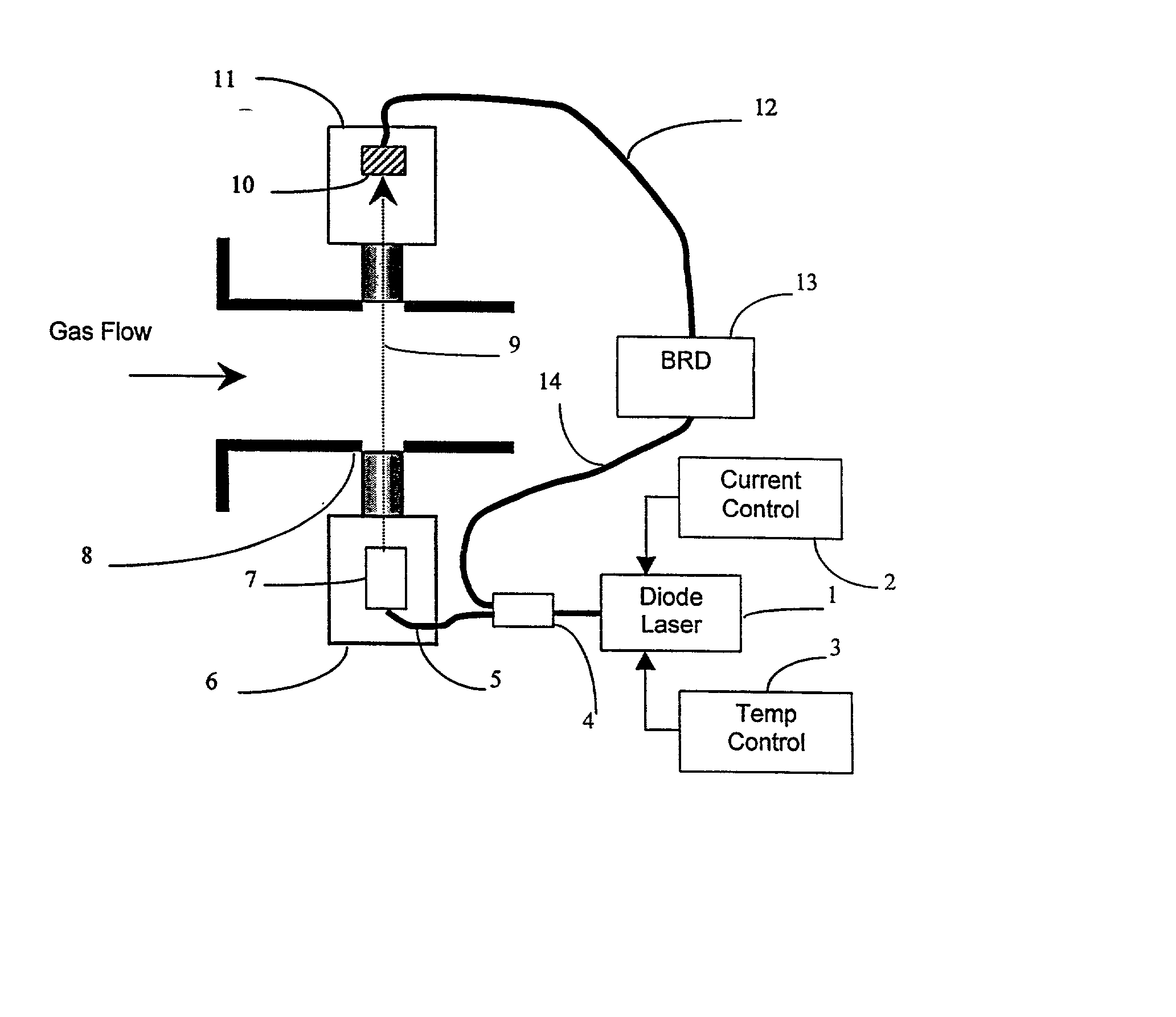

[0080] Implementation of the preferred monitoring method on a combustion process includes the following basic elements illustrated in FIG. 1. A single or multiple diode laser 1 is used in this embodiment. In the case of O.sub.2 monitoring the diode laser model 760DFB supplied by Sarnoff Corp. Princeton, N.J. is suitable. Each laser has a current controller 2 and temperature controller 3 for stability and wavelength tuning (such as available from Melles Griot, Carlsbad, Calif., model 56DLD403). The output of diode laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com