Automatic transmission fluids with improved anti-shudder properties

a technology of automatic transmission and anti-shudder, which is applied in the direction of lubricant composition, organic chemistry, fuels, etc., can solve the problems of unsatisfactory performance of old standards of performance previously met with approval, not all additives interact predictably or well with one another, and are one of the most expensive to diagnose, repair or repla

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

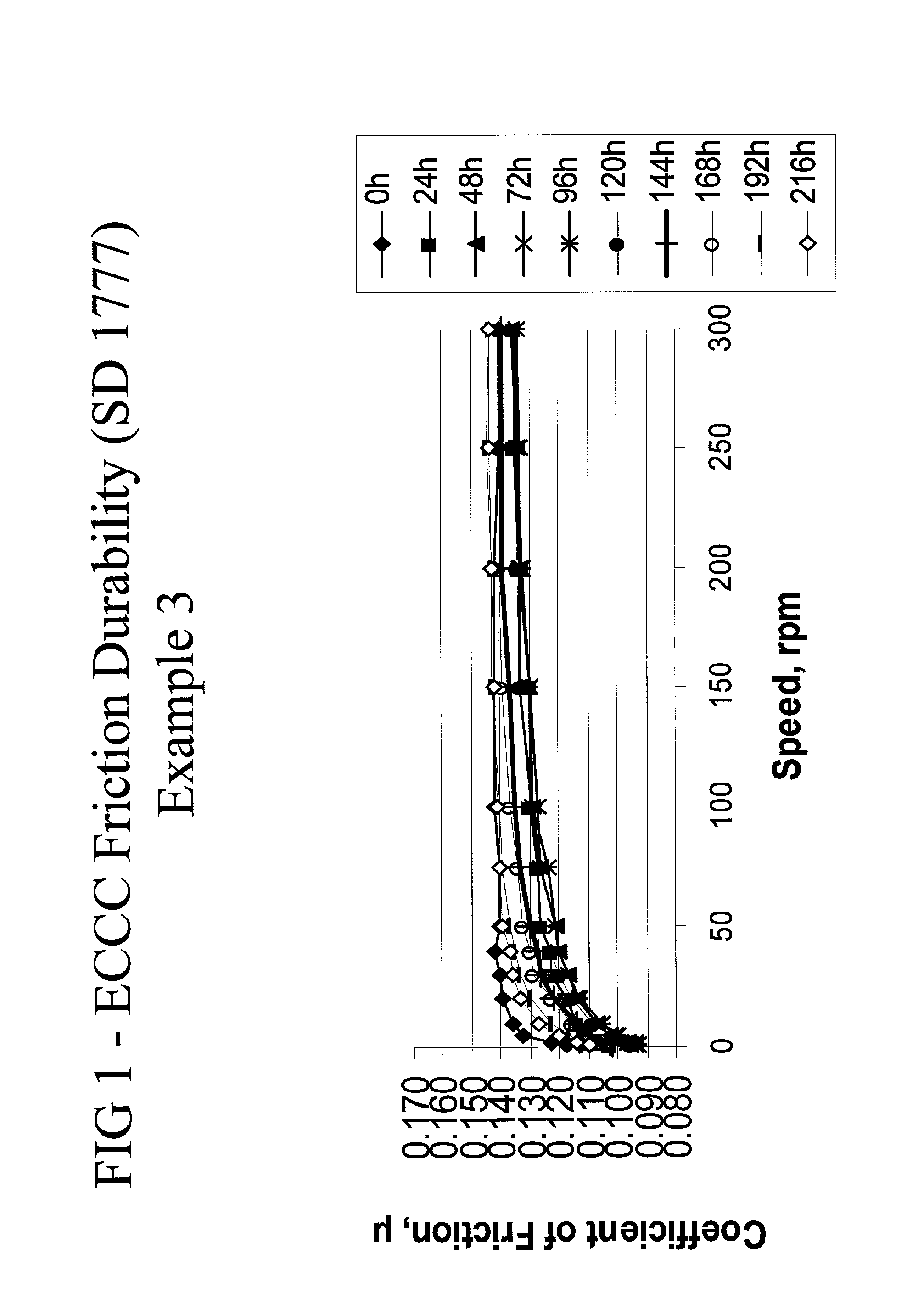

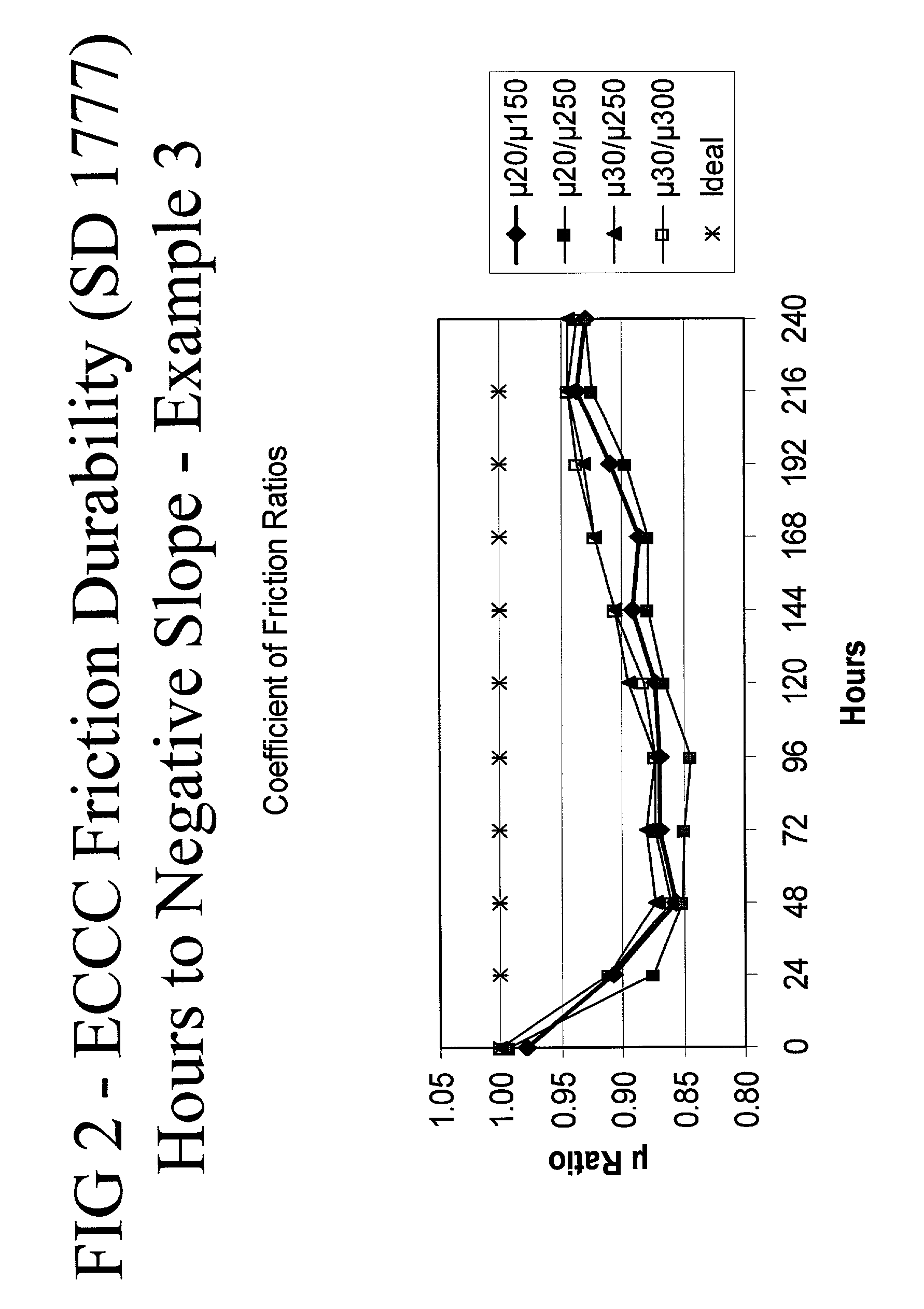

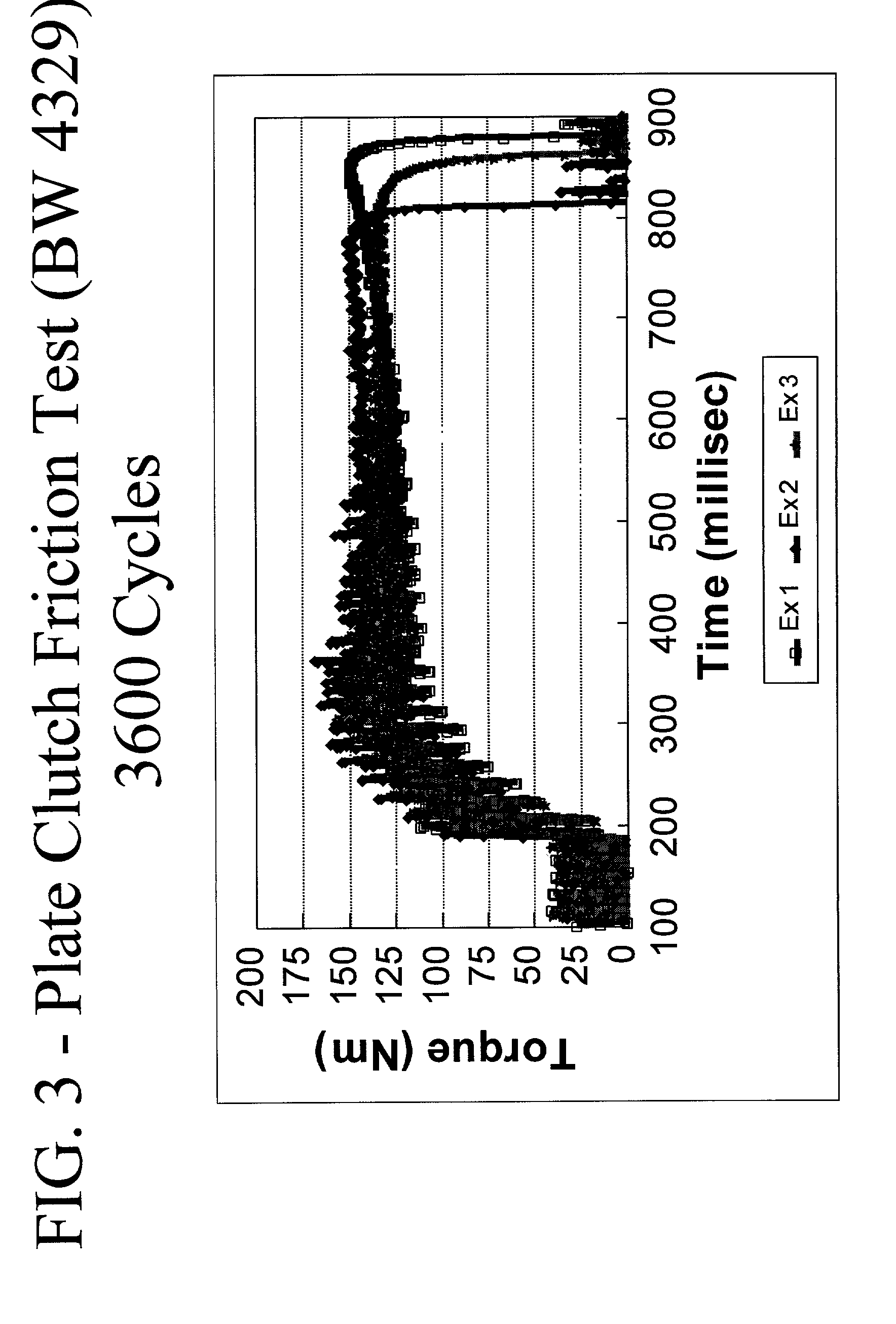

[0140] Illustrative compositions suitable for use in the practice of this invention are presented in the following Examples, wherein all parts and percentages are by weight unless specified otherwise.

[0141] The fluids prepared in the Examples were then subjected to testing under commonly known tests, including the low speed SAE #2 rig, under the conditions noted, and the GM plate clutch friction test (GM performance specification GM 6417 M, April 1997) run according to Dexron.RTM. III procedures. Briefly, this test involves engaging the clutch at the rate of four cycles per minute for 100 hours (i.e., 24,000 cycles) at 135 degrees C. The DEXRON.RTM. III Band Clutch Test limit for the mid-point torque is 185-220 Nm.

[0142] The GM Dexron III Cycling Test (GM-6297-M), revised April 1993; corresponding to the Ford Mercon V Friction Durability Test (Dexron 5 Specification 3.9, Revised Jul. 1, 1996 and Oct. 1, 1998 which sets limits on shift times for 20,000 shift cycles. Shifting from 1st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com