Wetcell device for inspection

a wet cell and lens technology, applied in the direction of measurement devices, structural/machine measurement, instruments, etc., can solve the problems of difficult to locate the lens, let alone inspect the lens, and achieve the effect of simple inspection system and without significant optical distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

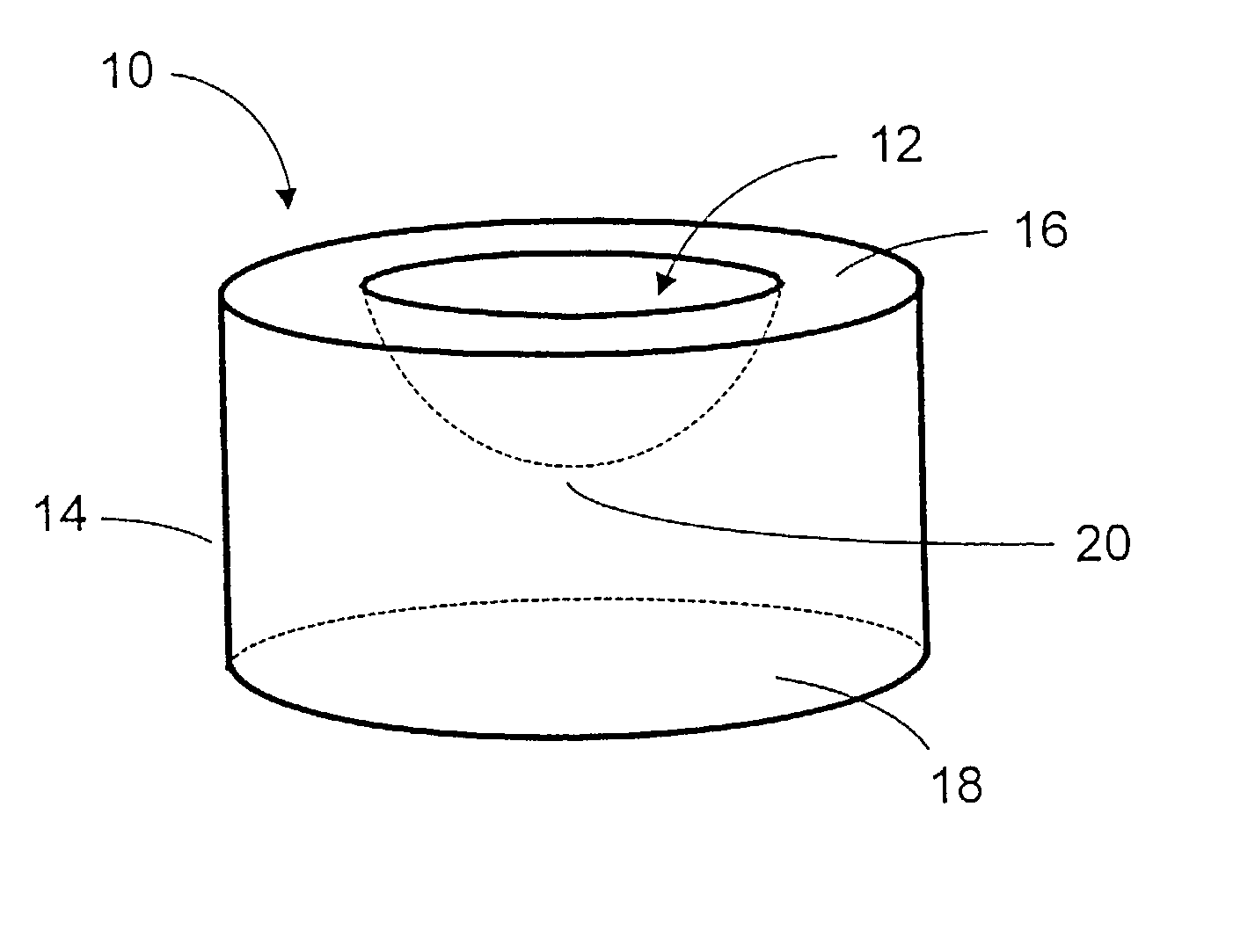

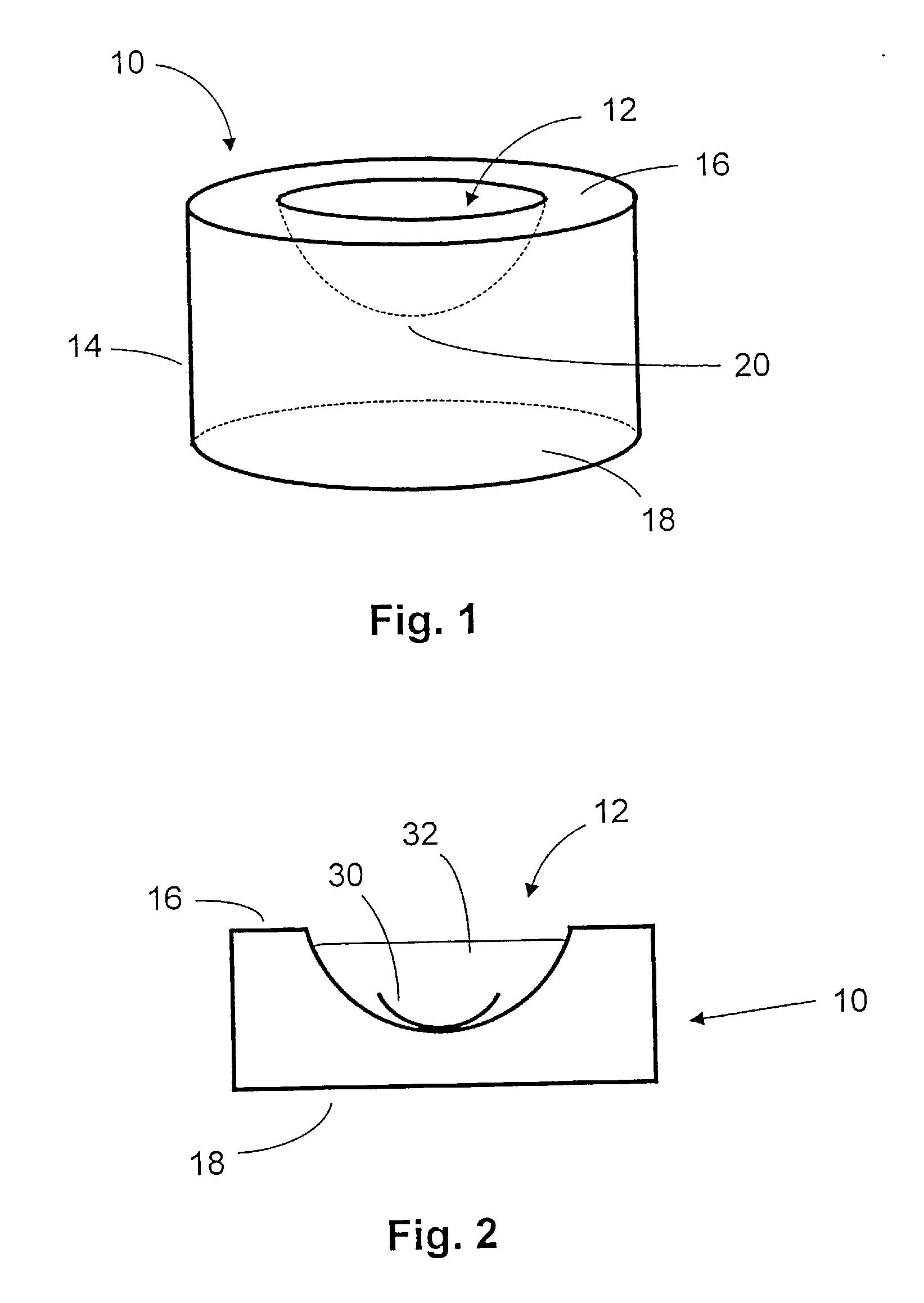

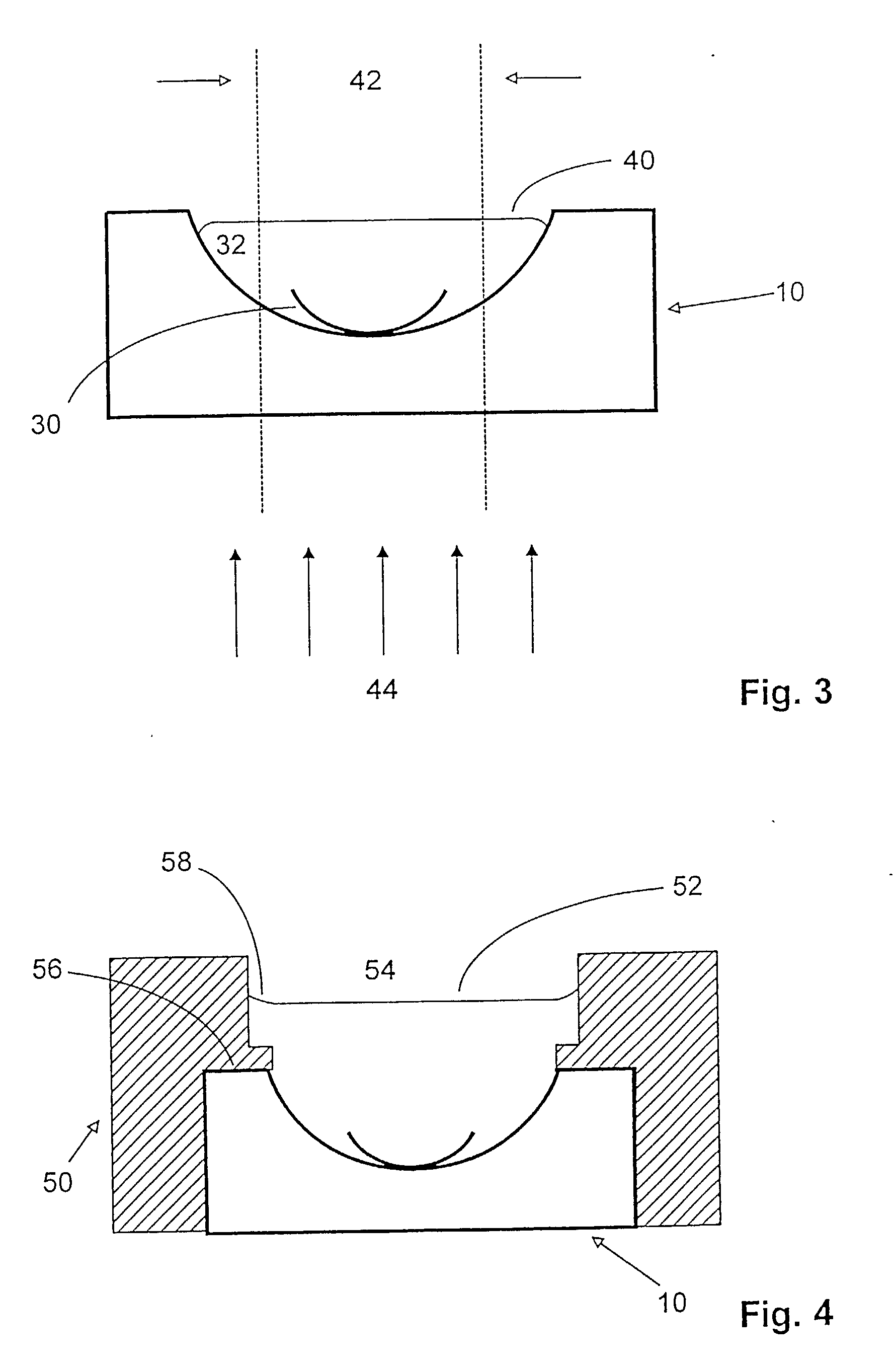

[0029] A reusable inspection cell is produced from quartz. A cylindrical quartz block, having a diameter of about 22.2 mm and a length of about 8 mm and having two parallel planar surfaces, is ground to have a hemispherical indentation of an about 11 mm radius. The apex of the indentation is about 2 mm above the bottom planar surface of the quartz cylinder. The indentation and the lower planar surface of the quartz block are polished to have an optical finish. The resulting inspection wetcell exhibits highly uniform optical properties over the indentation and is highly scratch resistant, making the wetcell highly suitable for inspecting hydrogel contact lenses. The indentation is filled with an isotonic sodium chloride saline solution, and a hydrogel contact lens having a diameter of about 14 mm and a front curve radius of about 9 mm is placed in the indentation. The hydrogel lens consistently settles to the center of the indentation, and the high scratch resistance of quartz makes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com