Method of manufacturing electro-magnetic wave shielding yarn

a technology of electromagnetic wave shielding and manufacturing method, which is applied in the direction of yarn, textiles and paper, can solve the problem that applying this method to natural fibers cannot guarantee the durability against laundering, and achieve the effect of good shielding materials, perfect solid color, and sufficient shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

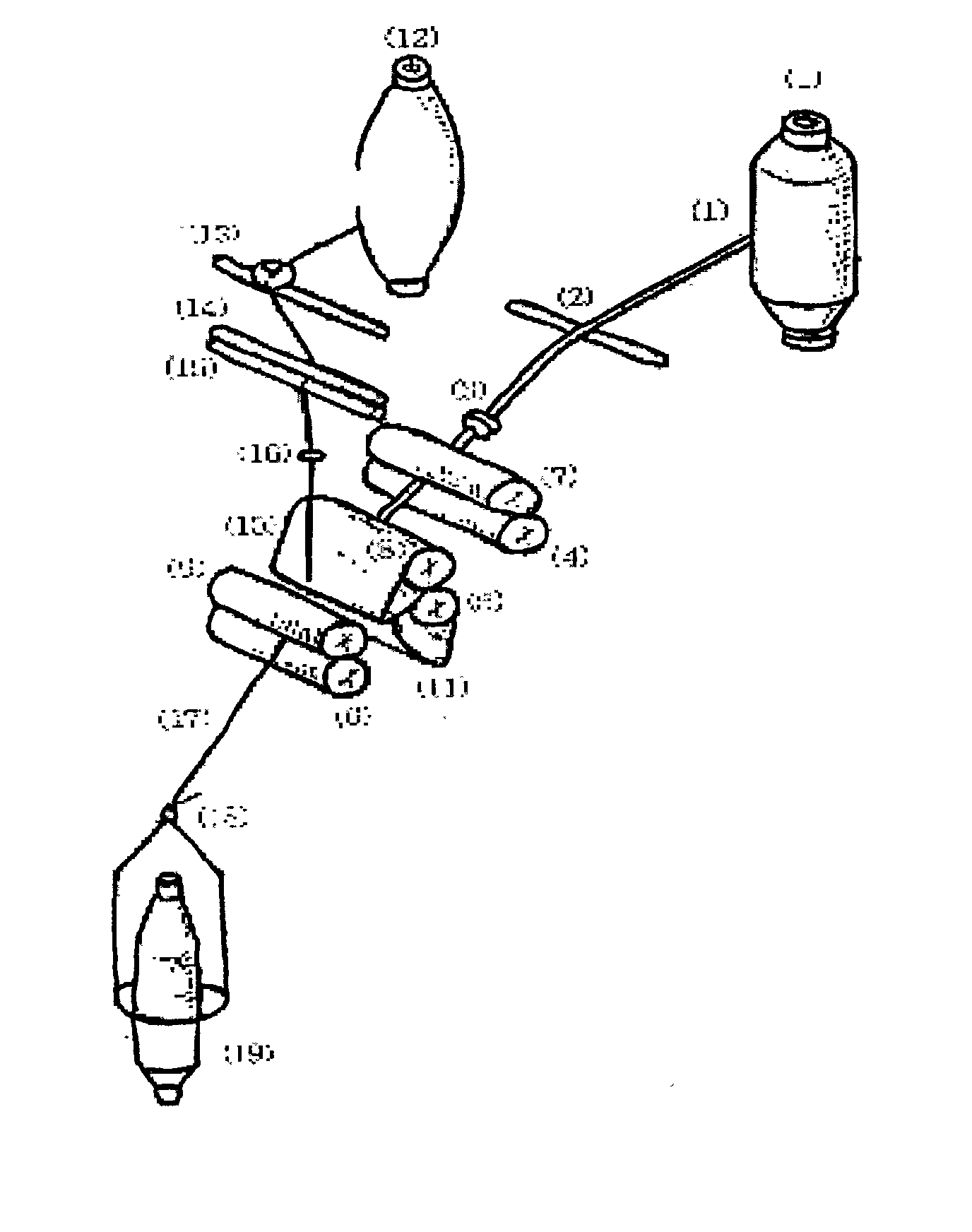

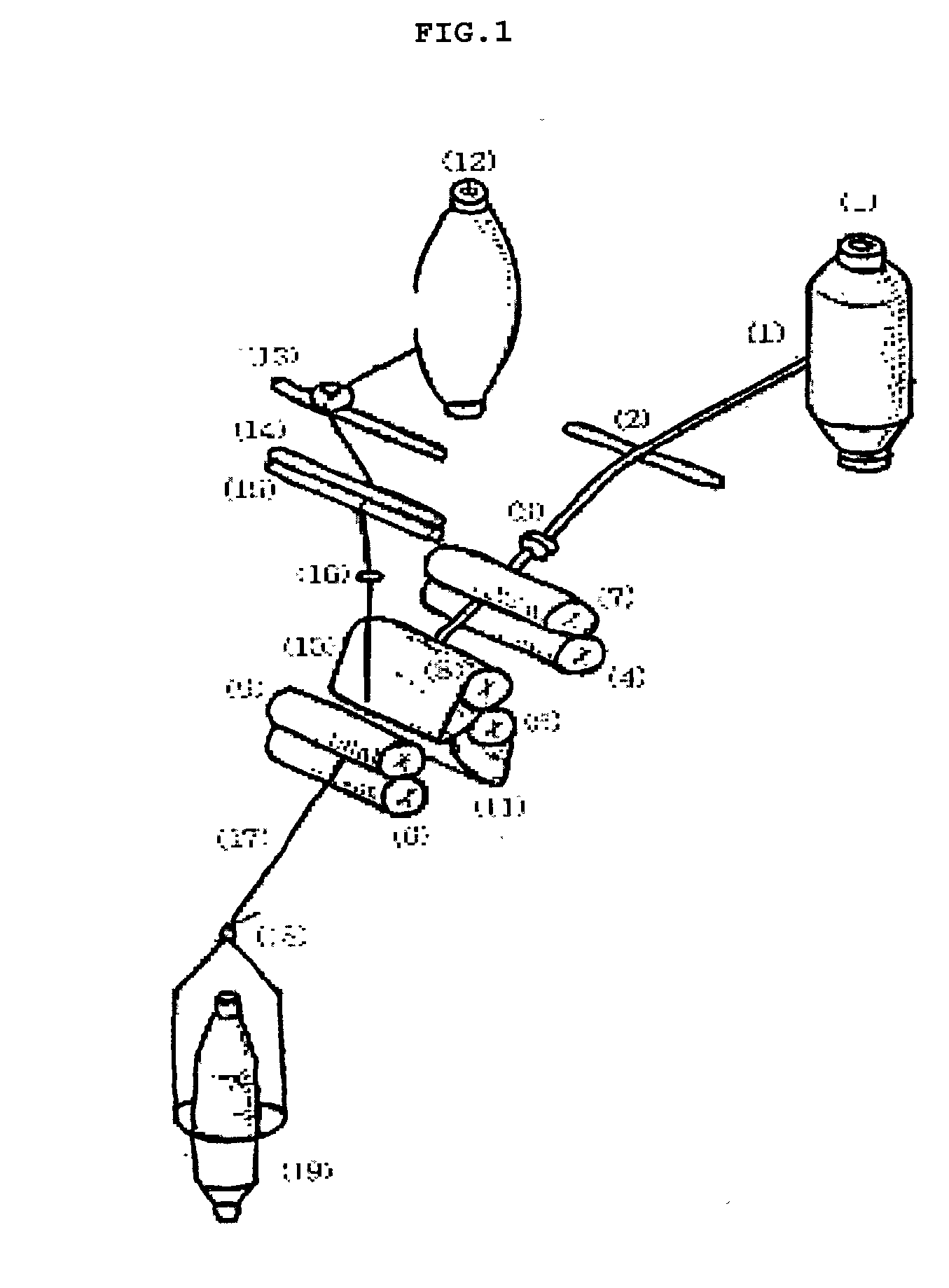

Method used

Image

Examples

example 2

[0022] Roving of cotton was made with conventional method. Copper wire of 0.03 micron and polyester mono filament of 20 denier were twisted with twists of 720 per meter. These twisted yarns were supplied to the tension applying device, adjusting draft ratio to 1.08 through which these yarns were fed to the front rollers. Prepared roving was supplied to the same front rollers through back and middle rollers. The core spun yarns were twisted with twists of 18 twists per inch and the yarn number was 16 in English cotton count. These core spun yarns were knitted with regular cotton yarn of 20 E.C.C. and were arrayed once every 7 regular cotton yarns. The knitted fabric was dyed cotton side only.

[0023] Perfect solid color was acquired. The feeling of the fabric was as good as that of conventional cotton fabric. Effect of electromagnetic wave shielding was 71.5%. Antibiotic degree was 99.5%. Voltage of anti-static charge was 654 volts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface velocity | aaaaa | aaaaa |

| durability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com