Liquid crystal display device, backlight used for same display device, method for driving same backlight and method for manufacturing same backlight

a technology of display device and liquid crystal, which is applied in static indicating devices, instruments, non-linear optics, etc., can solve the problems of unavoidable rise in fabrication costs, component count increase, and unsatisfactory performance of conventional lcds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

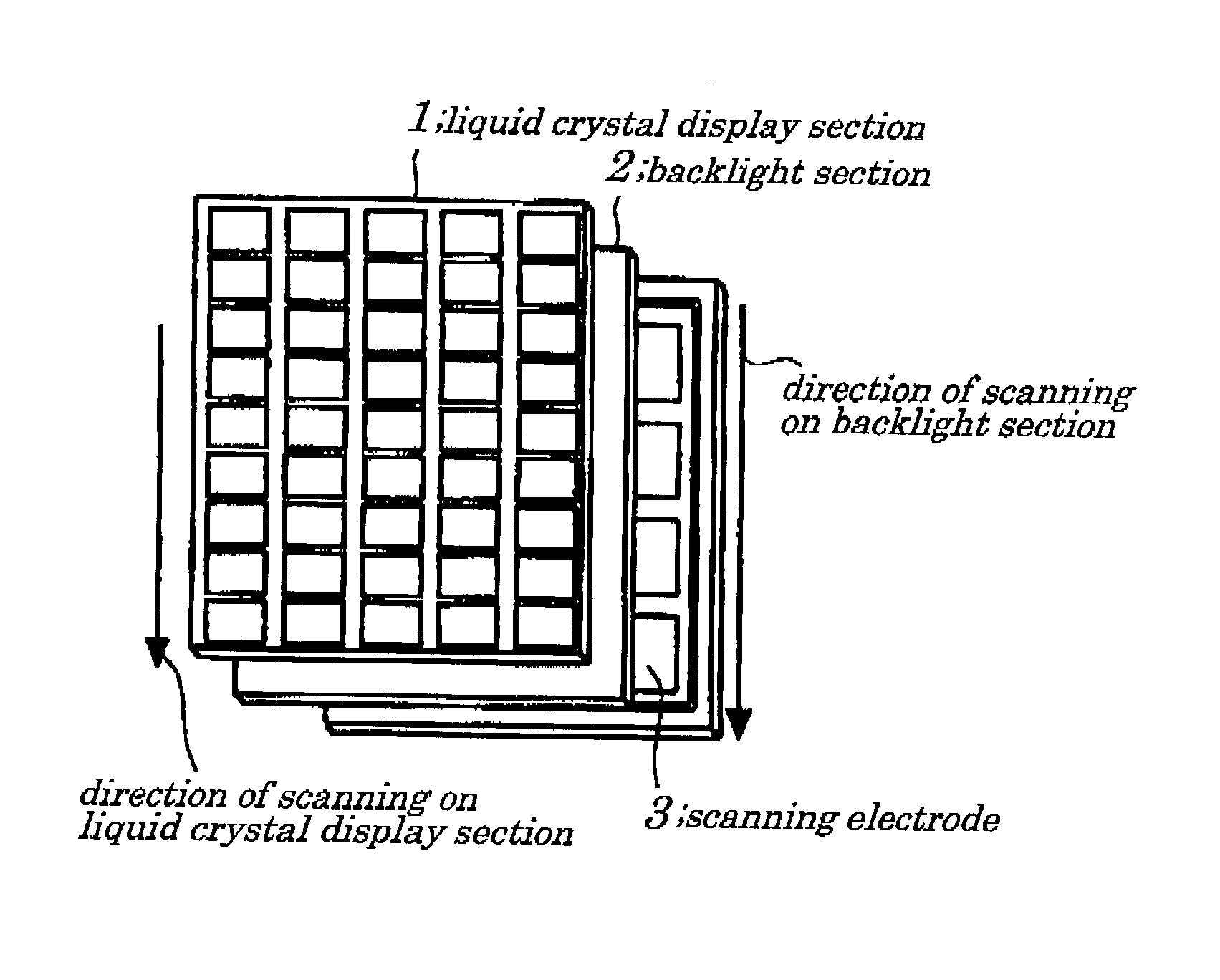

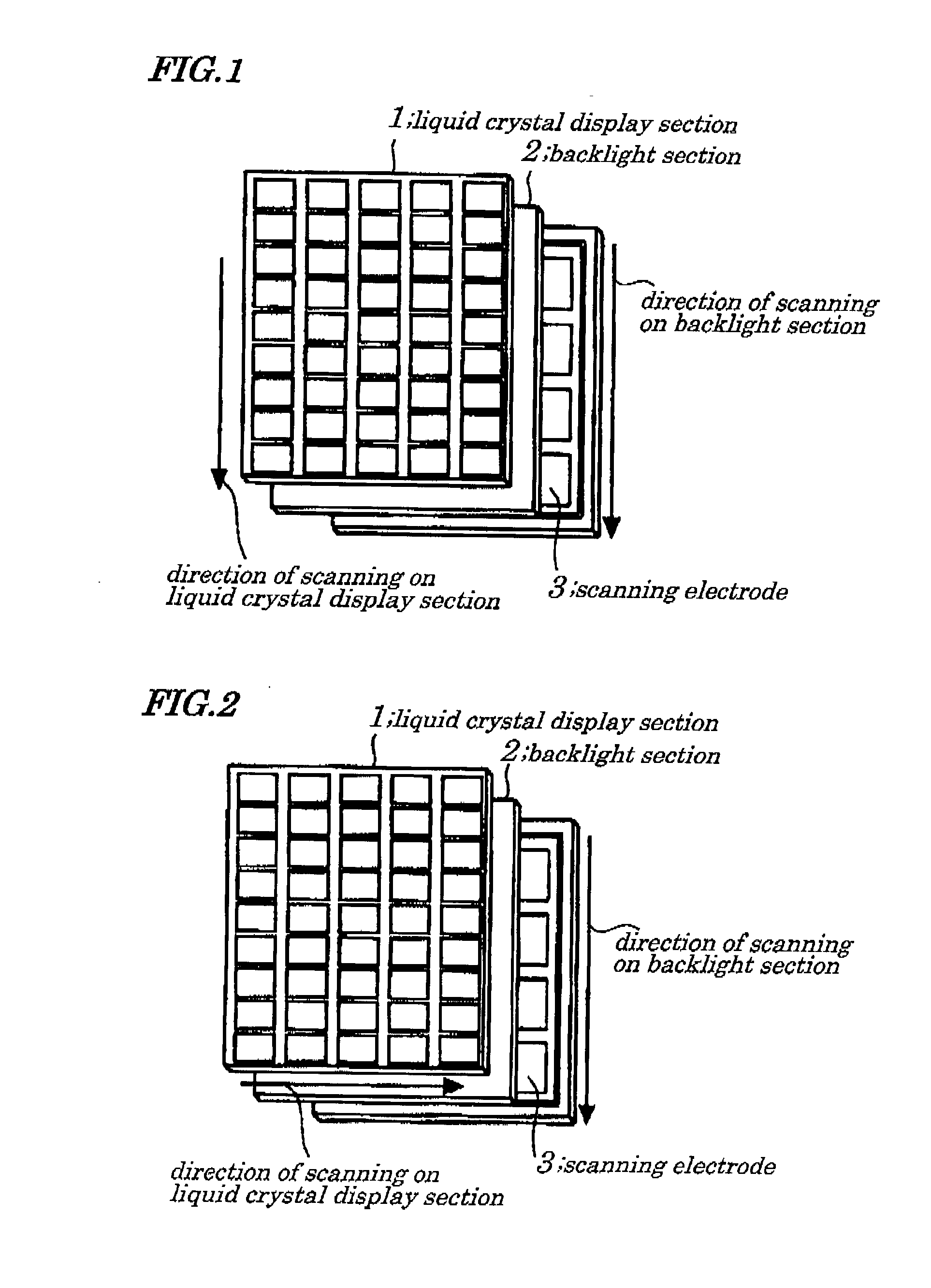

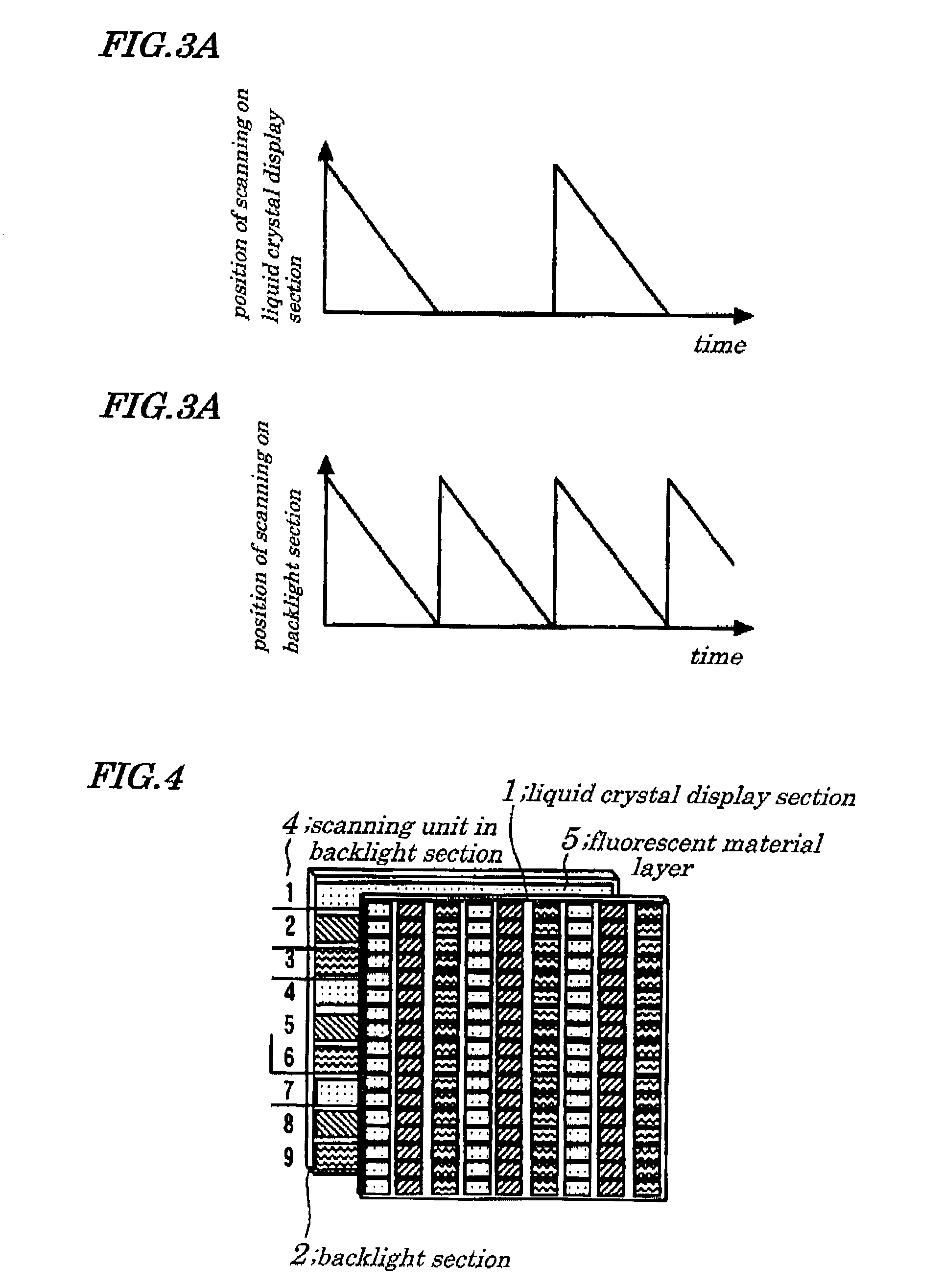

[0284] An example of the present invention will be described below. FIG. 35 is a cross-sectional view schematically illustrating basic configurations of a gas discharging-type backlight used in the present invention. In FIG. 35, in the backlight of the example of the present invention, a common electrode 102 made up of a transparent conductive film made by using an indium oxide or tin oxide as a main ingredient is formed on an entire surface of a displaying region of a first glass substrate 101. The first glass substrate 101 and the common electrode 102 make up a front glass substrate 100.

[0285] On a second glass substrate 201 is formed, in order to control a region of emitted light, short-book shaped scanning electrodes 202 fabricated by using a metal thin film or metal particles as a main ingredient which are arranged in parallel in a direction traveling straight to a scanning direction or a metal fine particle, on which a white dielectric layer 203 is formed and finally a fluores...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com