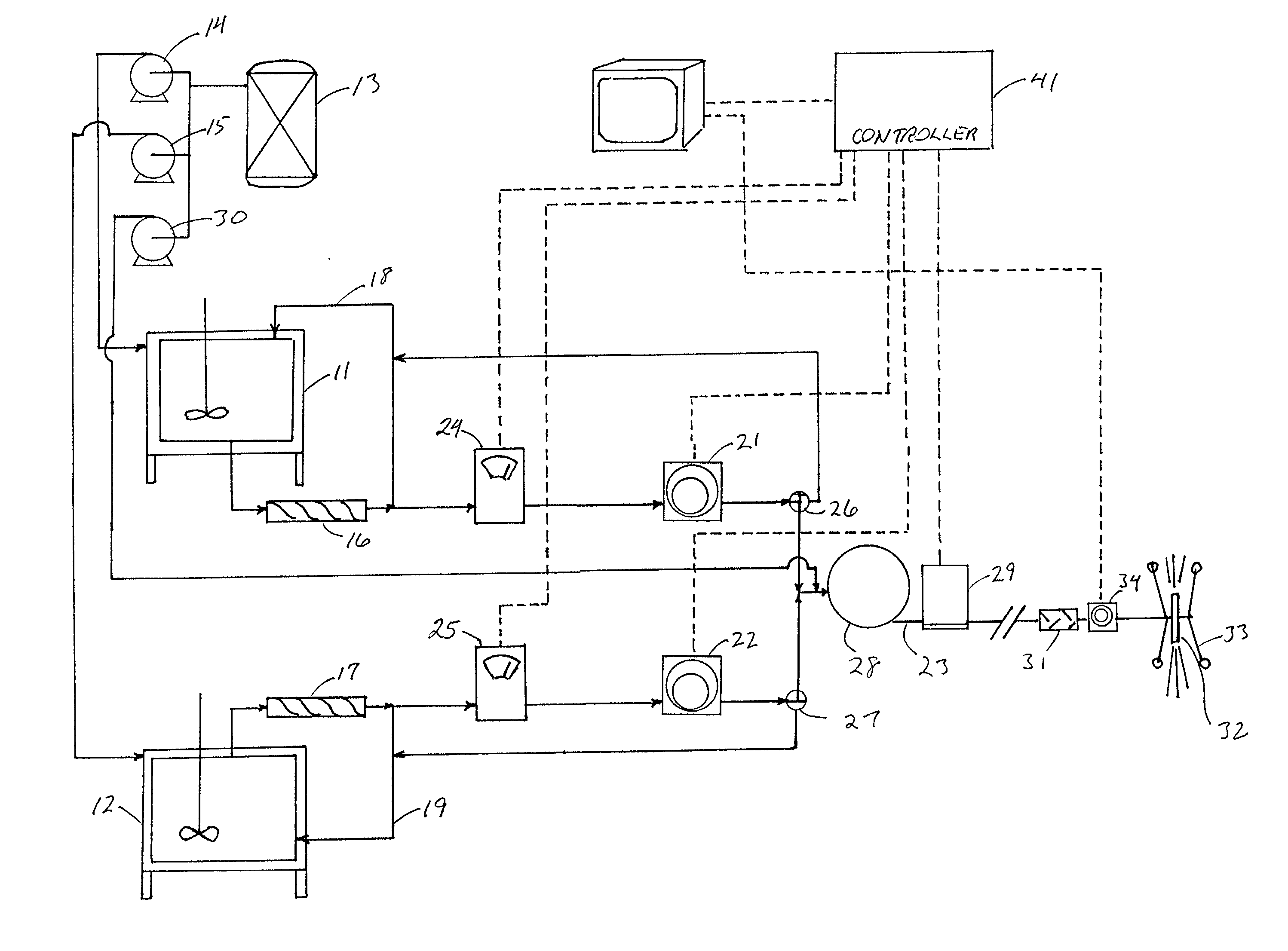

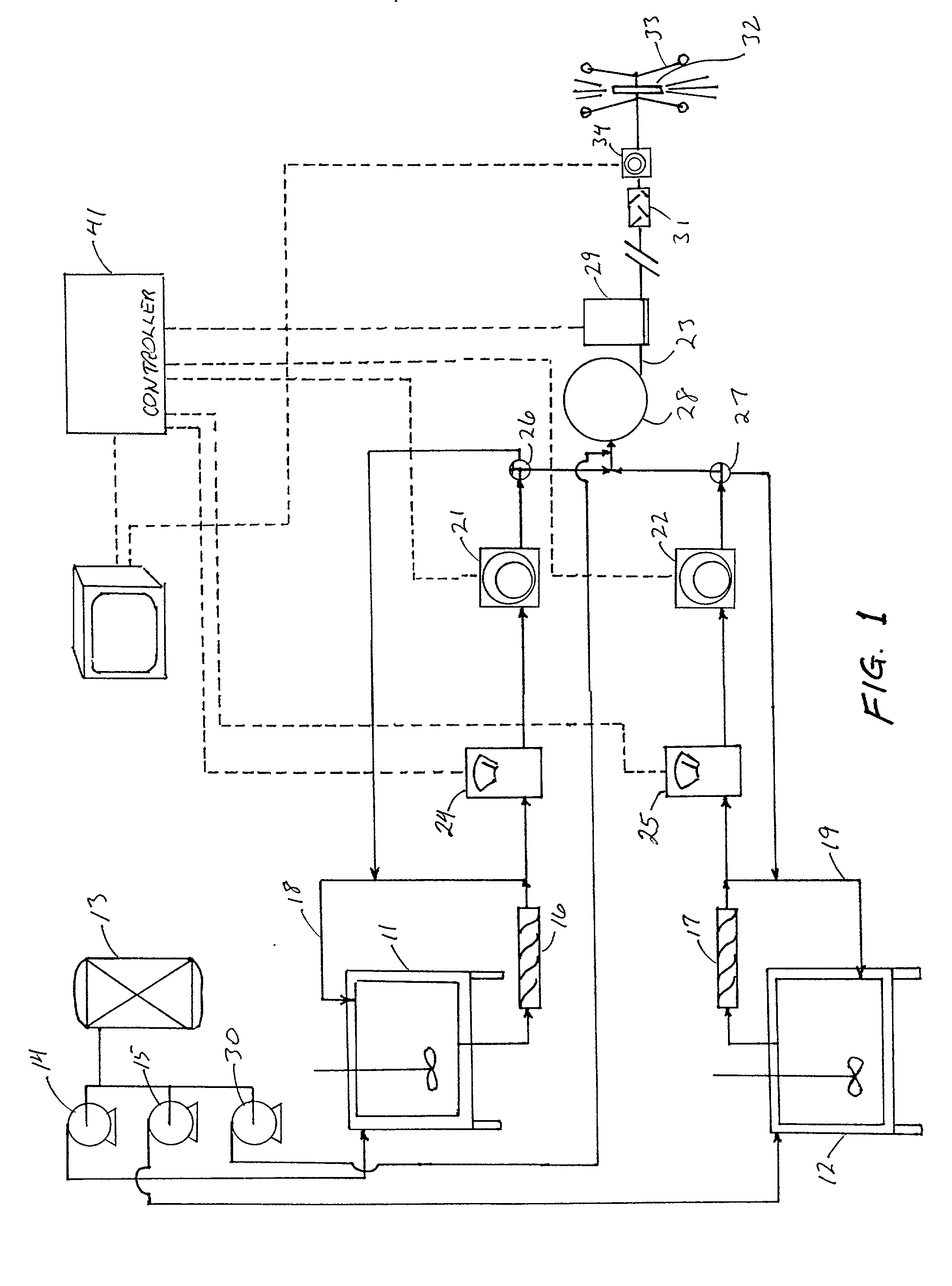

System and method for delivering reactive fluids to remote application sites

a technology of reactive fluids and transport systems, applied in the direction of positive displacement liquid engines, process and machine control, instruments, etc., can solve the problems of pipe deterioration, obstruction of flow through the pipe, pipe collapse,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

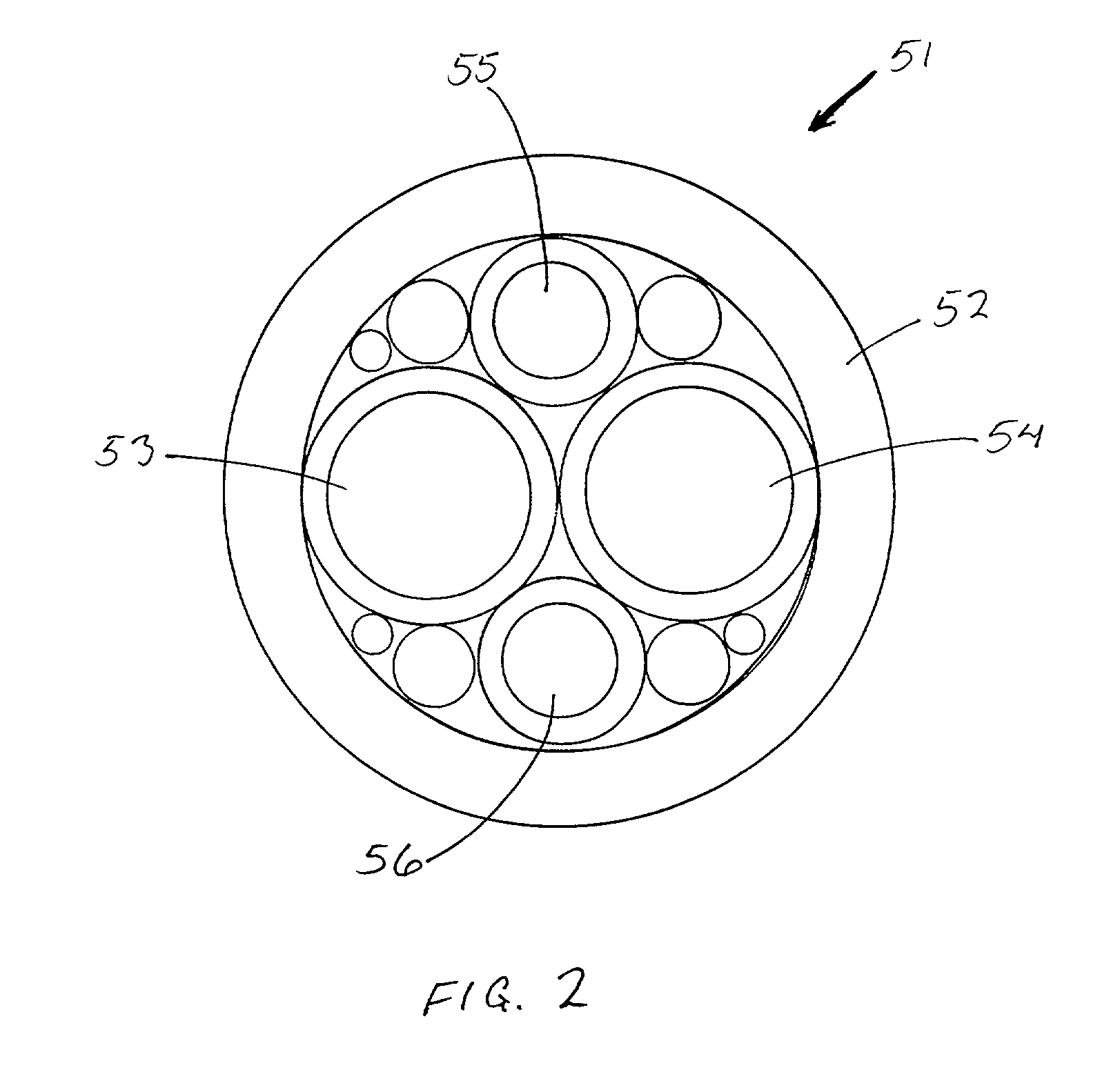

[0017] A crescent internal gear pump has two circular gears, i.e., an outer gear with inward-extending teeth that meshes with outward-extending teeth of an inner gear, both gears rotating within a common housing but on different parallel axes that place the gears in eccentric relation, leaving a crescent-shaped space between them. Much of the crescent-shaped space is occupied by a crescent-shaped insert that provides a close clearance between itself and the tips of the gear teeth. Either gear may serve as the drive gear, although preferably the inner gear is the drive gear. The gear teeth create voids as they come out of mesh, expanding as the gears rotate to create a suction to draw fluid into the space between the gears and hence into the pump. As the gears come back into mesh, the volumes around the teeth are reduced, thereby increasing the pressure and forcing the fluid out through a discharge port. The flow rate is thus determined by the rotation speed of the gears. Typical cre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com