Rumble strip cutter

a technology of rumble strip and cutter, which is applied in the direction of manufacturing tools, roads, and highways, can solve the problems of limiting the forward speed of the milling machine, and affecting the cutting effect of rumble strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example ii

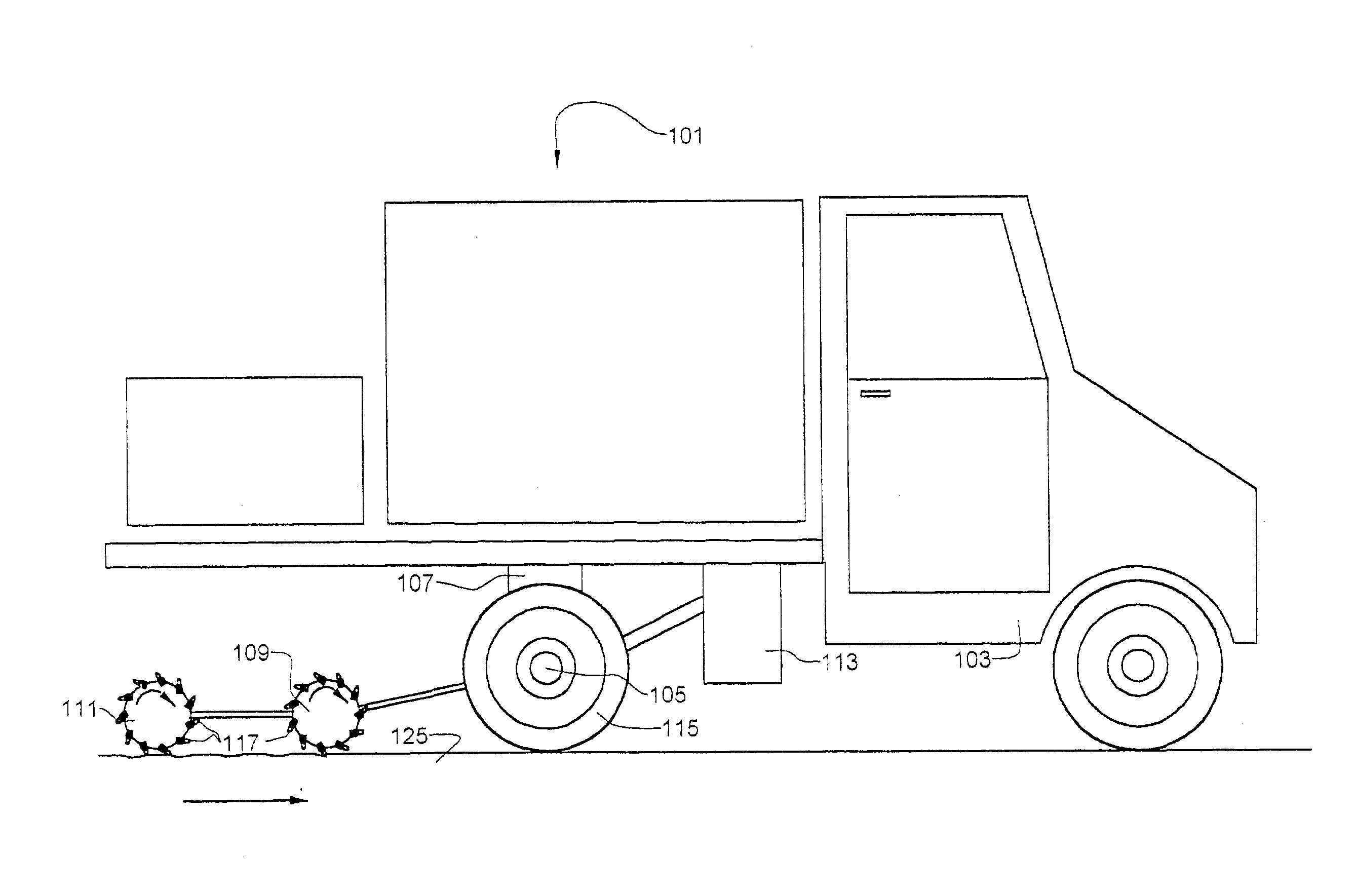

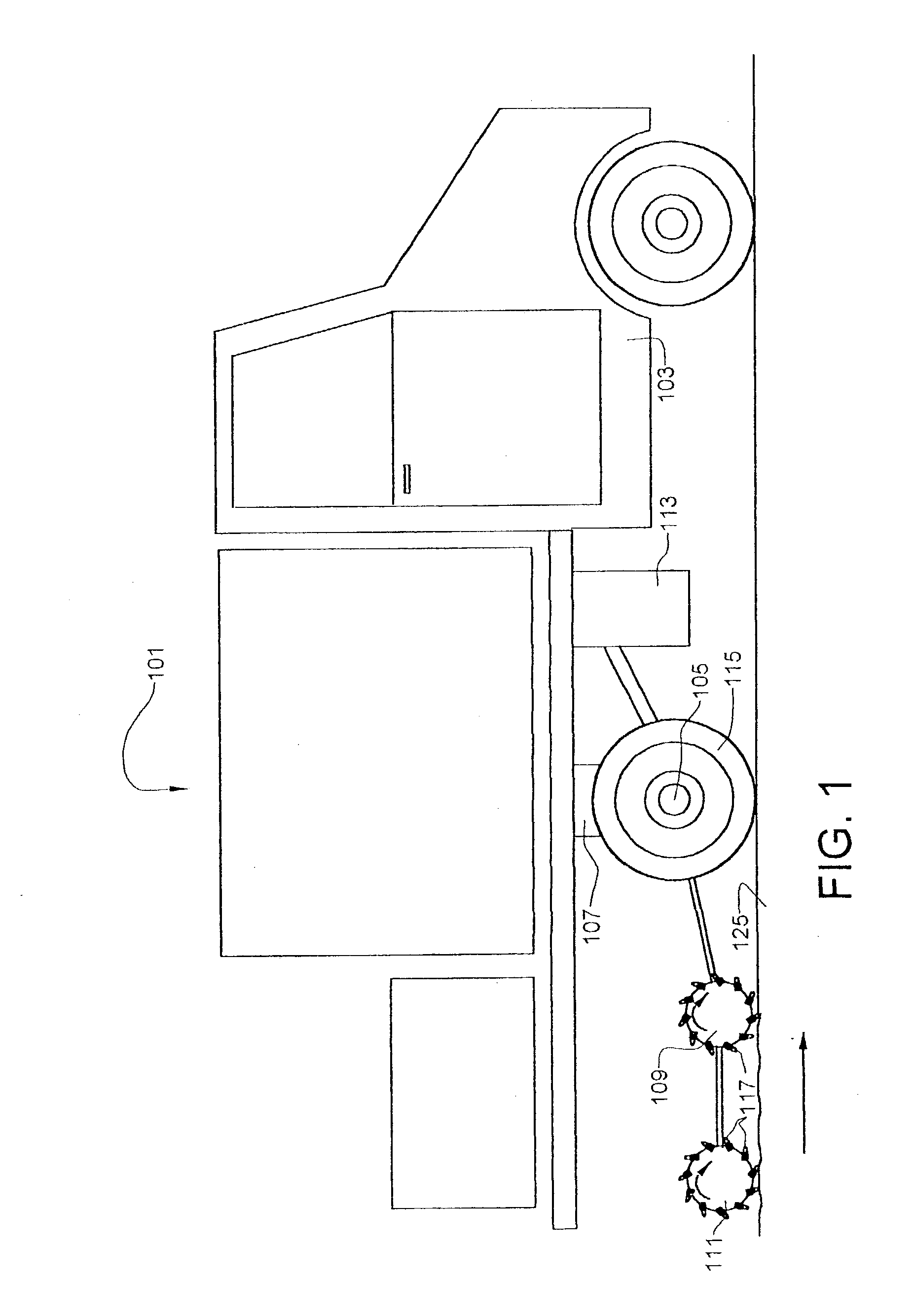

[0042] Reference is now made to FIG. 3, which a schematic diagram of an alternate rumble strip milling machine of the invention 301. A truck 303 with a suitable wheelbase and at least one rear drive axle 305 provides a forward motion to the apparatus. Four cutting wheels 309, 310, 311, 312 are mounted behind the drive axle. The truck is equipped with suitable means to raise and lower the cutting wheels (not shown).

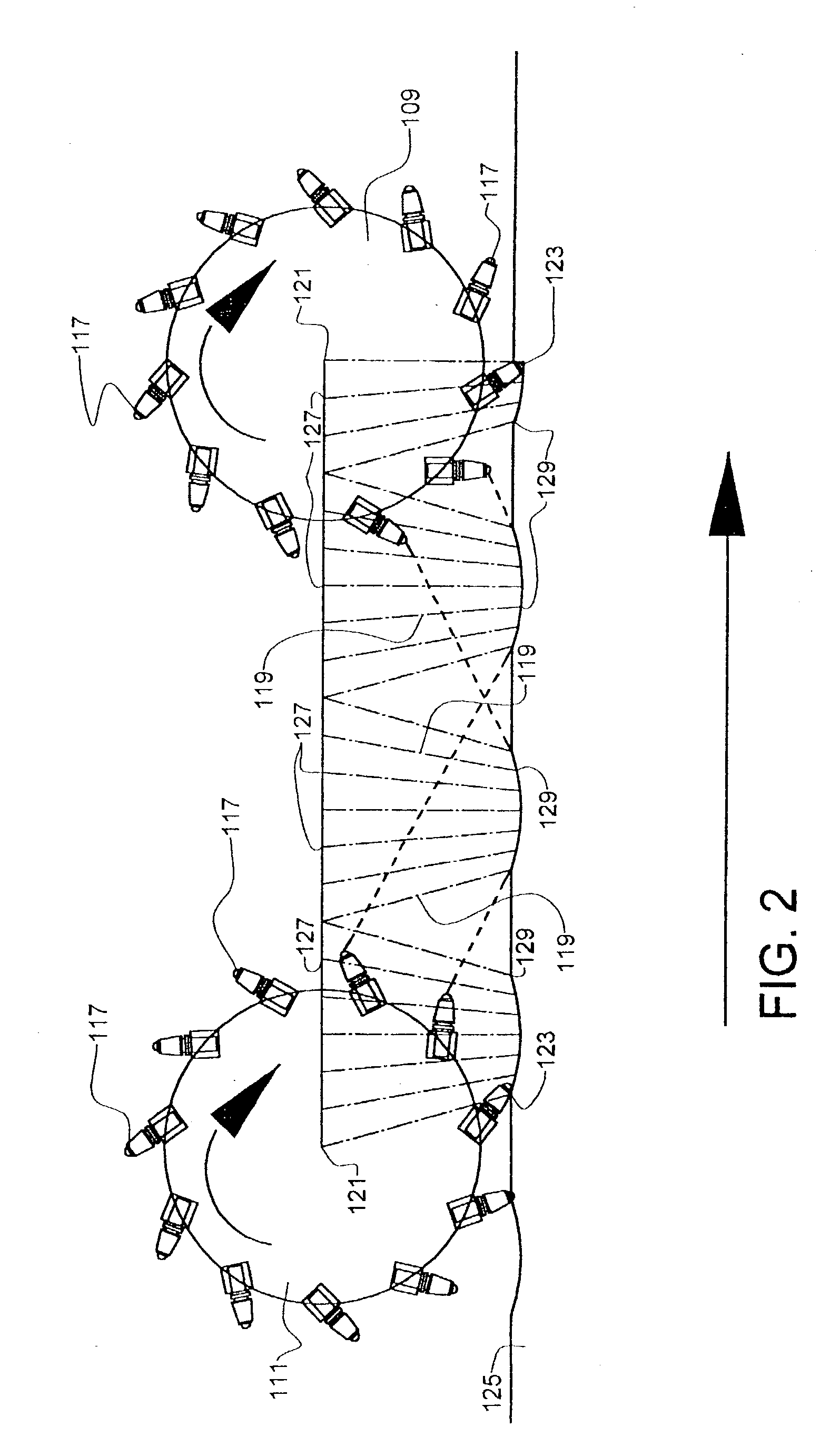

[0043] With driving wheels 315 on the machine of about 30.56 inches in diameter, and the cutting wheel one-fourth of that diameter (from tips of teeth -7.64 inches) a ratio of 8:1 would turn cutting teeth on the cutting heads twice as fast as the forward motion of the milling apparatus. The circumference of the cutting heads is about 24 inches which means that the teeth would travel 24 inches in a circular motion for every 12 inches of forward motion. Using four cutting wheels mounting 15 inches apart, each cutting wheel having one row of cutting teeth. In the four cutting...

example iii

[0046] Reference is now made to FIGS. 6 to 13, which show a milling apparatus 401 of the invention in which the cutting wheel 402 is placed at a non-perpendicular angle to the forward direction of travel. Referring to FIG. 6, a rear-axle assembly 403, essentially the same as that used on a motor vehicle, with the wheels 405 mounted at an angle is mounted on a trailer frame. The assembly is disposed at an angle so that the shaft 407, that in a motor vehicle would be a drive shaft, extends from the side frame at a non-perpendicular angle. The wheels 405 and the shaft 407 are connected though a differential assembly having the appropriate gear ratio. The wheels 405 and the shaft 407 are connected to the differential assembly 409 with appropriate couplings and u-joints. Disposed on the end of the drive shaft is a cutting wheel, which disposed at a non-perpendicular angle to the forward motion of the trailer. If it is desired to cut thin transverse grooves 408 in the pavement, the angle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com