Ship's steering unit whose angular position is servo-controlled by an electric motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

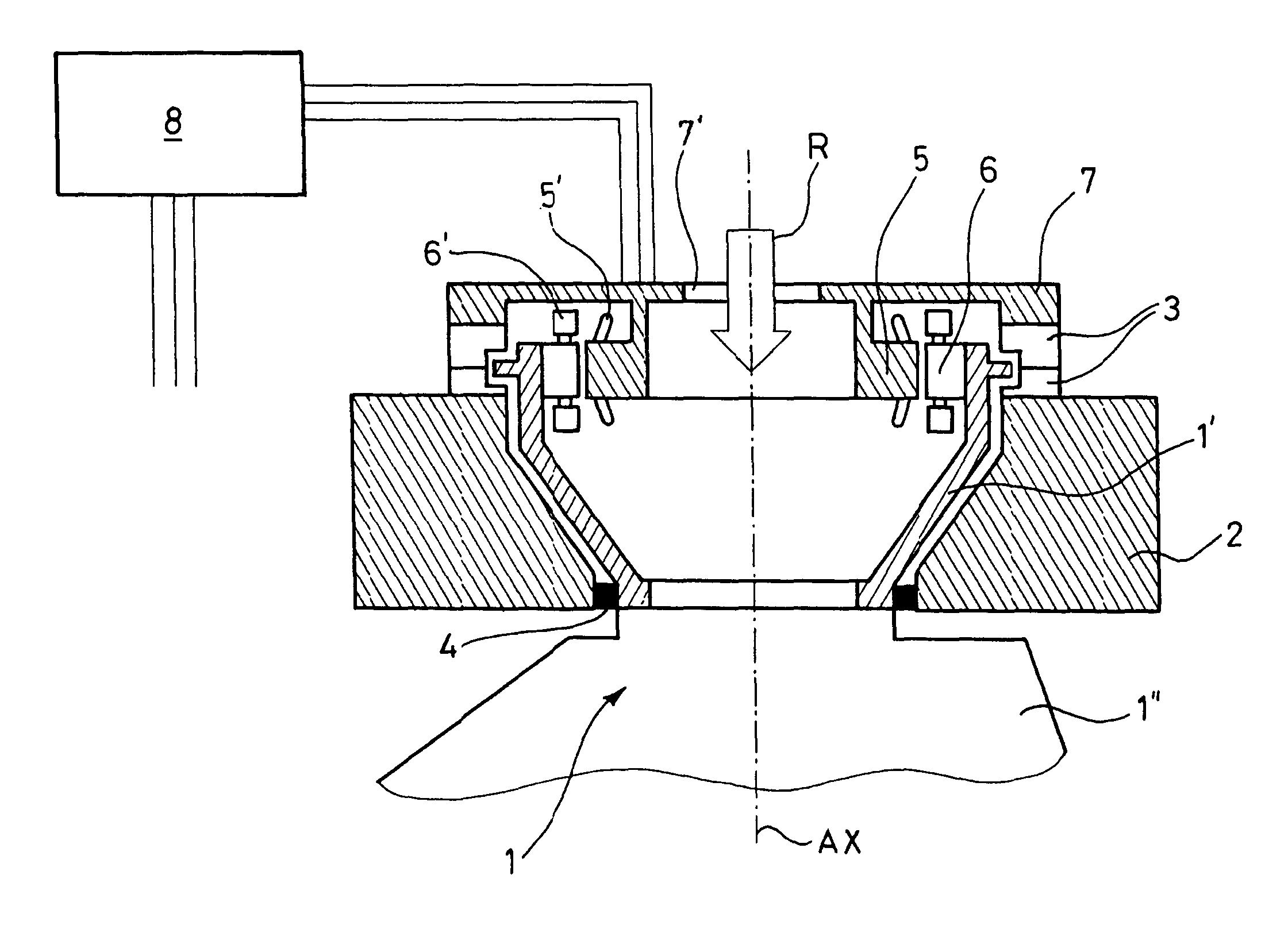

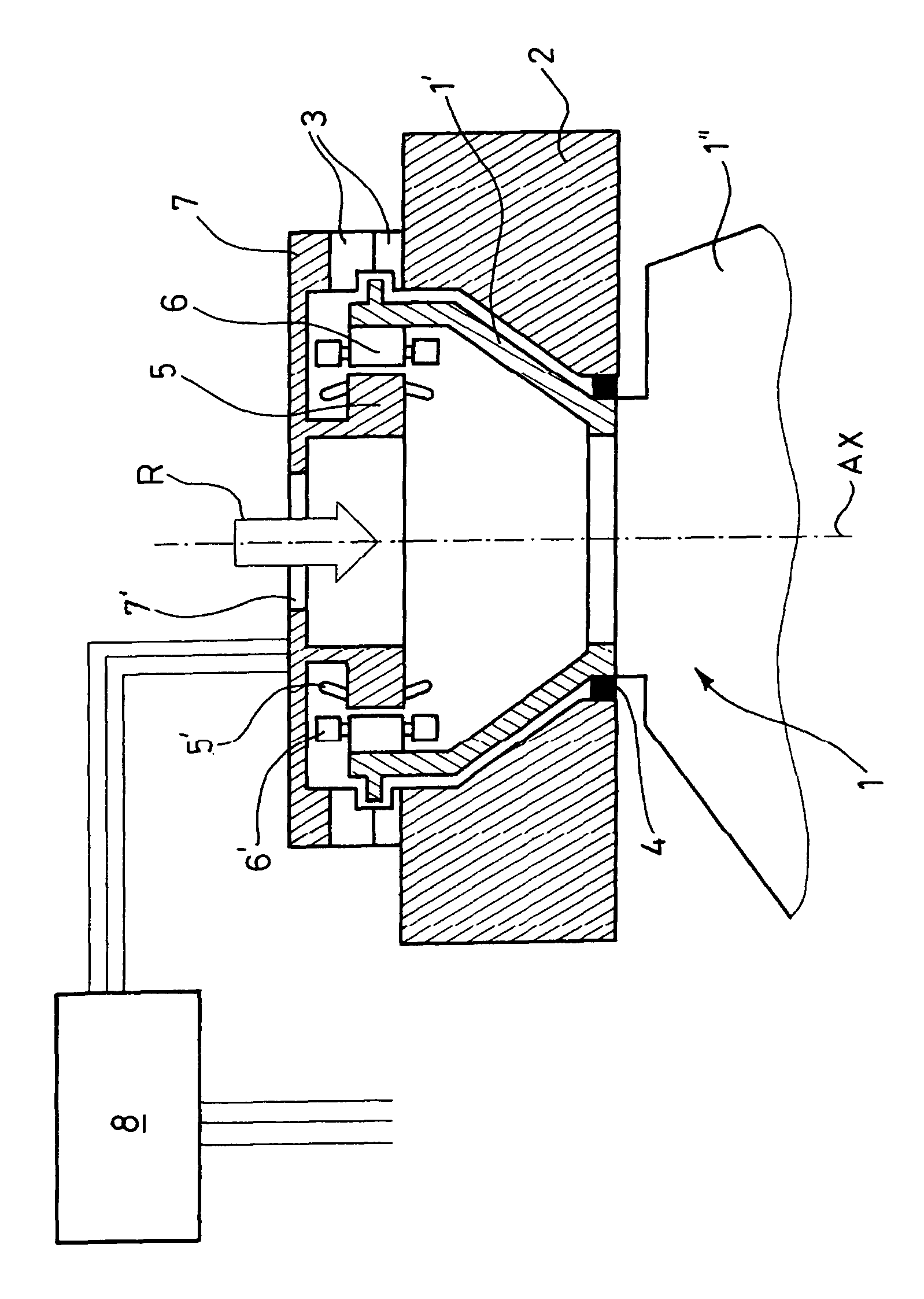

[0010] In the sole FIGURE, a ship's steering unit comprises a rudder 1 pivotally mounted in a mounting 2 that is secured to or integral with the structure of the ship. In this example, the rudder 1 is provided with a steering cone 1' connected to the mounting 2 via a rotary mechanical coupling 3 enabling the rudder to turn about a vertical axis AX along which it extends. The steering cone 1' passes through the structure of the ship in watertight manner to hold an underwater portion 1" which is shown in part only. The underwater portion 1" is fixed rigidly to the steering cone 1' and it forms the active portion of the rudder 1 to steer the ship on a certain heading depending on its position about the axis AX. The angular position of the rudder 1 about the axis AX is controlled by servo-controlling the angular position of the steering cone which is situated inside the ship.

[0011] In the example shown in the FIGURE, the diameter of the steering cone 1' decreases from top to bottom, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com