Shoe pattern design method, shoe pattern design device, foot measurer, and foot positioning device of foot measurer

a technology of shoe pattern and design method, which is applied in the field of shoe pattern design device, foot positioning shoe pattern design device of foot measurer, can solve problems such as troublesome process, and achieve the effect of facilitating the production of shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0033] A. First Embodiment

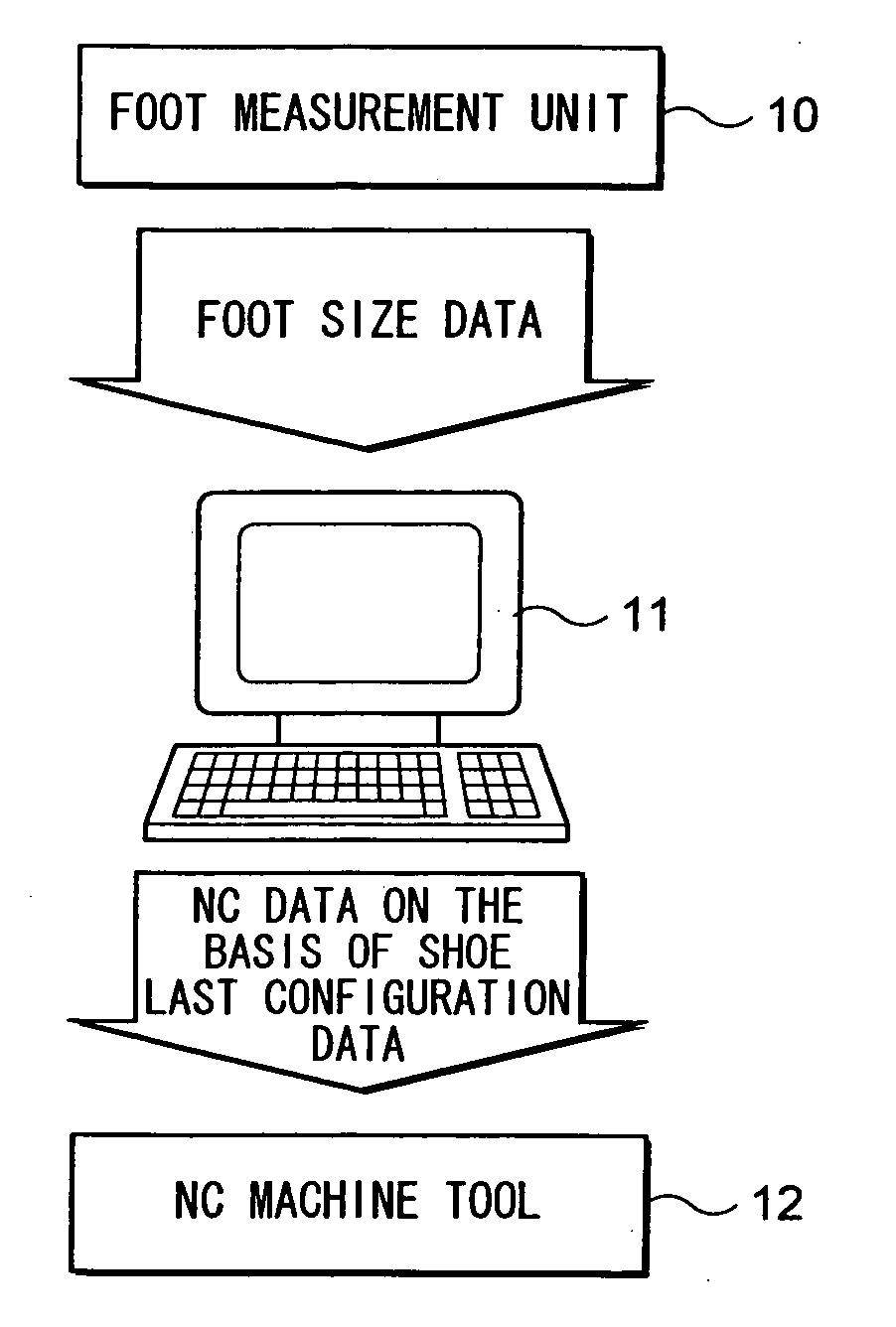

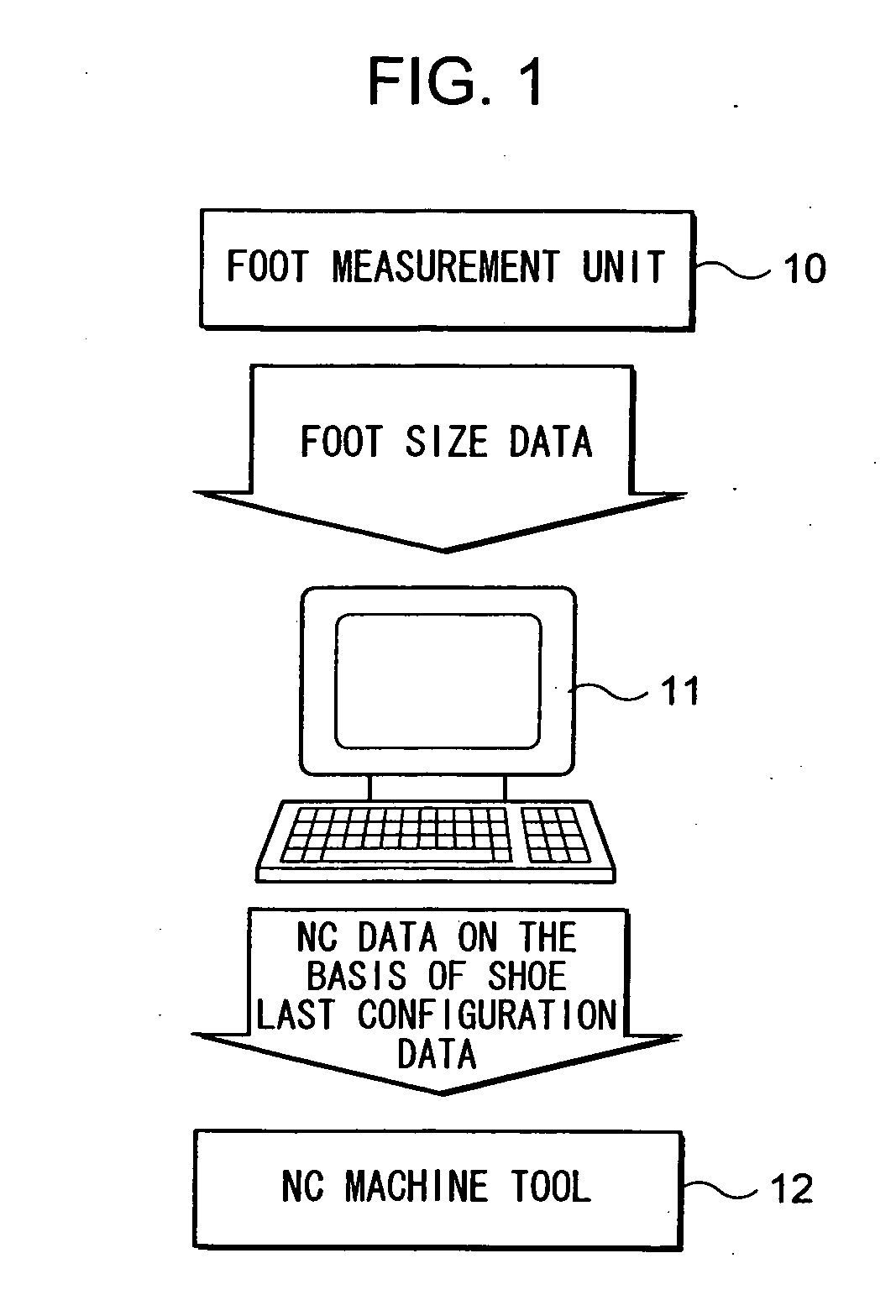

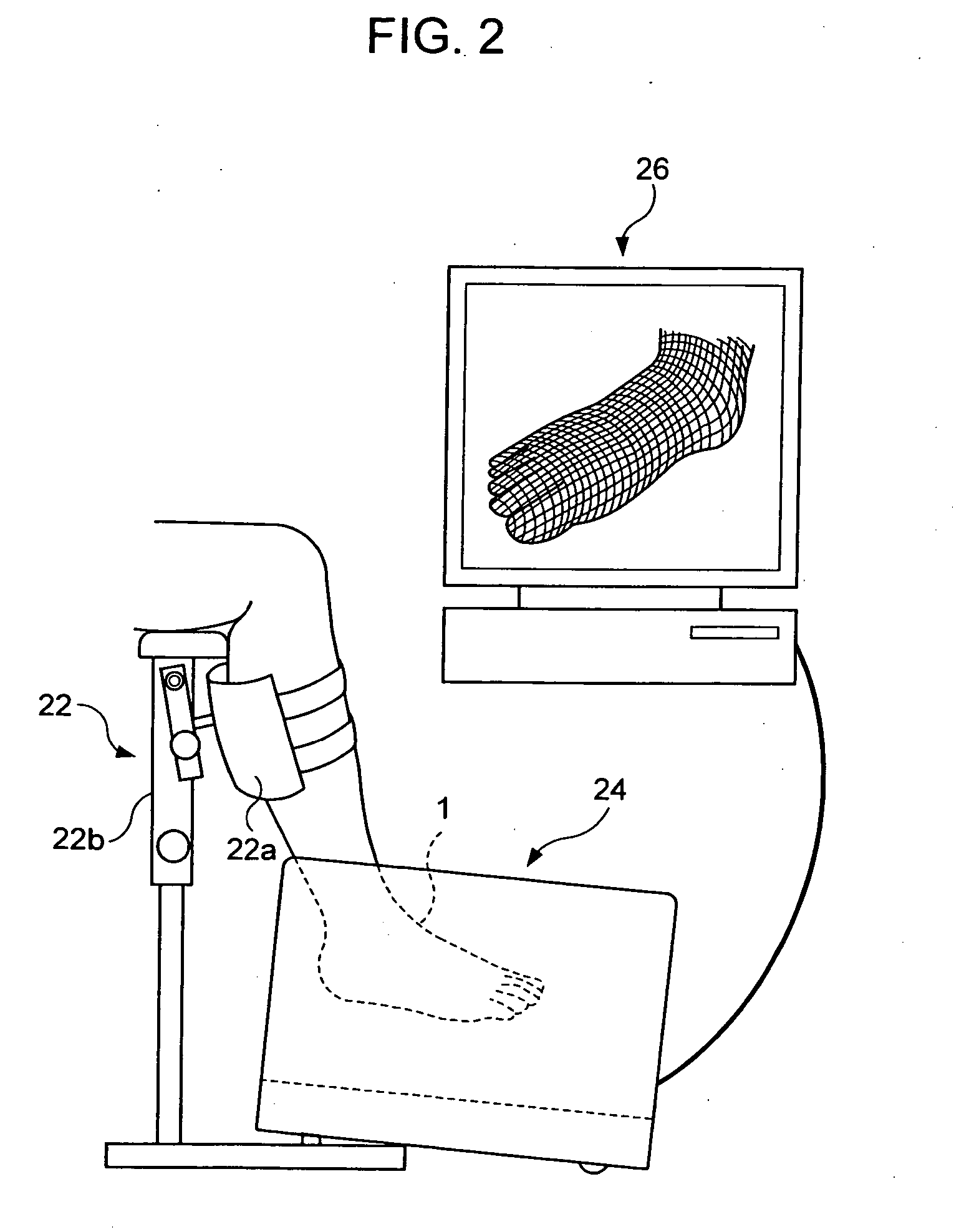

[0034] First, as shown in FIG. 1, the shoe last manufacturing system of the present embodiment comprises foot measurement unit 10, personal computer system (shoe last design unit) 11, and NC (Numerically Controlled) machine tool 12.

[0035] Foot measurement unit 10 is a unit for producing size data showing a foot size of a user by measuring the configuration of a foot of the user. Foot measurement unit 10 uses a non-contacting type three dimensional configuration measurement unit in the present embodiment as shown in FIG. 2. As shown in FIG. 2, foot measurement unit 10 comprises tightening unit 22, foot configuration measurement unit 24, and displaying unit 26. Tightening unit 22 prevents movement of the user's foot during measurement, and comprises, as shown in the figure, rolling unit 22a to be rolled around a calf of the user, and supporting unit 22b for supporting and fixing rolling unit 22a. As shown in the figure, rolling unit 22a is rolled around the c...

modification 6

[0081] (Modification 6)

[0082] When a shoe last configuration data production process is carried out, in which the design of the ordered shoe (for example, a design where the tip of the shoe is square), or configuration data of the shoe last (for example, taking the height of the heel and so forth into account) can automatically be produced, shoe last data can be produced by preparing a conversion table for classification of a plurality of designs of shoes or the height of each heel (for example, 0 to 1 cm, 1 cm to 2 cm), choosing a conversion table in accordance with the designated design or height of the heel, and referring to the chosen conversion table.

modification 7

[0083] (Modification 7)

[0084] In the above-mentioned modification, when configuration data of a shoe last taking into account information such as the design of the shoe, the height of the heel, the type of the foot (such as Egyptian foot, Greek foot, hallux valgus, or pes latus), fleshiness of the user's foot (for example, subcutaneous fat percentage) is produced, a plurality of conversion tables are prepared, and when the foot type is Greek foot, the conversion table corresponding to Greek foot is chosen and referred to. By preparing several conversion tables in this manner, configuration data of shoe lasts taking into account the several types of information mentioned above can be produced, but on the basis of configuration data of the shoe last produced by shoe last configuration data production unit 32 of the first embodiment mentioned above, the basic configuration data can be amended by taking into account information such as the design of the shoe, the height of the heel, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com