Material having characteristics of high thermal conductivity and electromagnetic interference resistance

a technology of electromagnetic interference resistance and thermal conductivity, which is applied in the field of materials having characteristics of high thermal conductivity and electromagnetic interference resistance, can solve the problems of insufficient heat dissipation area, inability to provide enough heat dissipation area, and inability to meet the needs of high-power electrical devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

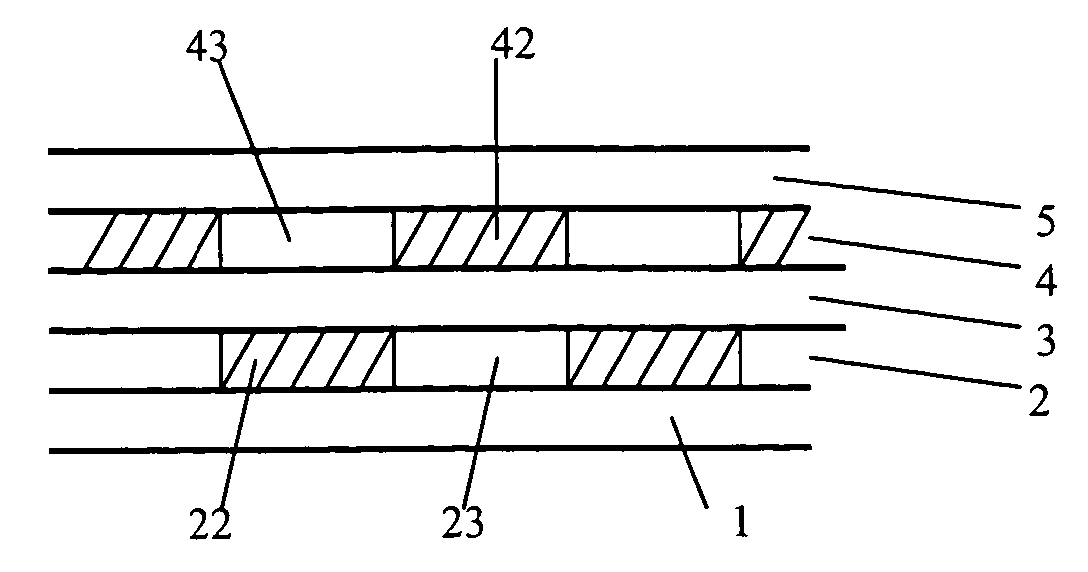

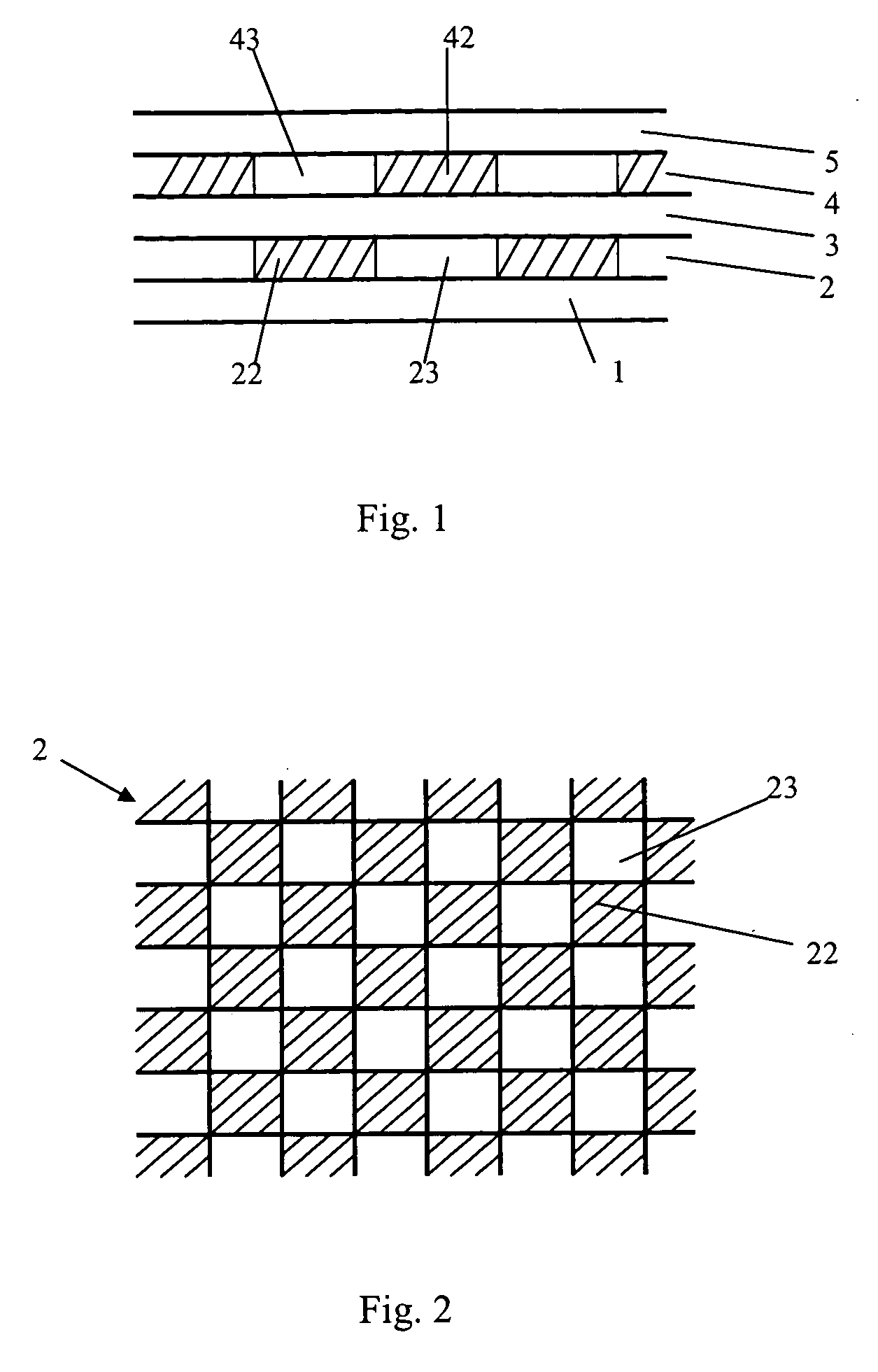

[0023] Referring to FIGS. 1 and 2, a compound material having the characteristics of high thermal conductivity and electromagnetic interference (EMI) resistance of the present invention is shown.

[0024] FIG. 1 shows a sectional sketch view of the compound material. The compound material comprises a first high heat conductive layer 1, a first EMI shielding layer 2, a second high heat conductive layer 3, a second EMI shielding layer 4 and a third high heat conductive layer 5.

[0025] The amounts of the heat conductive layers (1, 3, 5) and the EMI shielding layers (2, 4) can be adjusted according to actual requirements. The thickness of each heat conductive layer (1, 3, 5) or each EMI shielding layer (2, 4) can be pre-set according to actual application environments.

[0026] The second heat conductive layer 3 is superposed over one side of the first EMI shielding layer 2, which is opposite to the first heat conductive layer 1. The second EMI shielding layer 4 is overlapped over one side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat conductive | aaaaa | aaaaa |

| shielding | aaaaa | aaaaa |

| electromagnetic wave absorbing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com