Magneto-optical head having heat sink layer

a heat sink layer and magnetic technology, applied in the direction of instruments, disposition/mounting of heads, light beam reproducing, etc., can solve the problems of deteriorating optical characteristics of lenses, deteriorating magnetic characteristics, and still remaining problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

fifth embodiment

[0122] The fifth embodiment is a modified embodiment of the fourth embodiment, which will be explained with reference to FIGS. 17 to 20. In this embodiment, a magneto-optical head was produced by providing a protective pad 91 as shown in FIG. 17 in place of the projection 70 of the magnetic coil substrate produced in the fourth embodiment. The magnetic coil substrate as described above can be produced as follows. In the process steps shown in FIGS. 6(a) and 6(b), the reactive etching is performed while providing the mask not only for the protruding section 50 of the substrate 3 but also for an outer circumferential portion corresponding to the projection 70. Accordingly, the projection 70 can be formed to have the same height as that of the protruding section 50. The protective pad 91 may be bonded onto the projection 70. The protective pad can be formed with resin as described later on. As shown in FIG. 18, for example, a frame-type pad 91, which was provided on the entire outer ci...

sixth embodiment

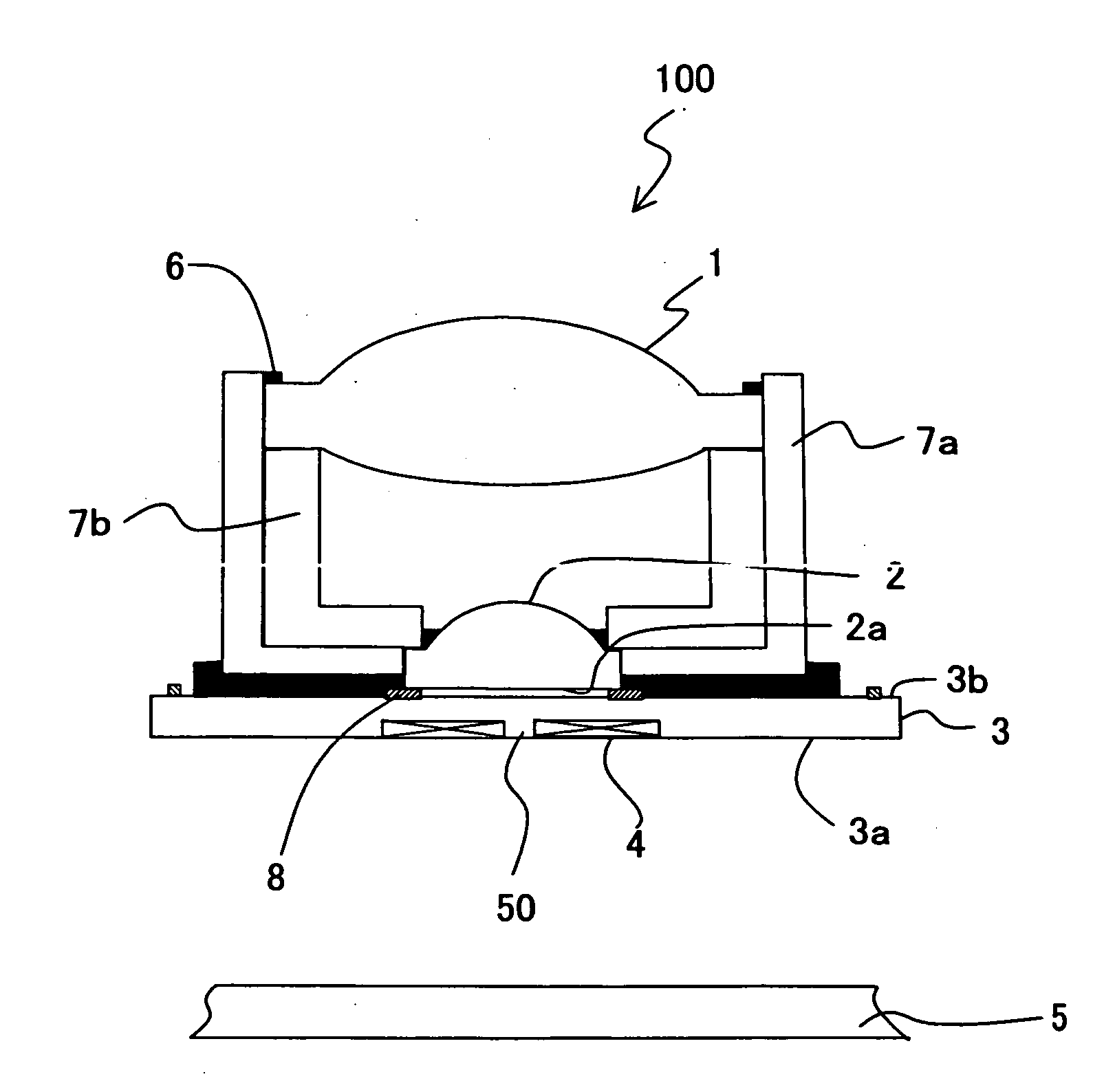

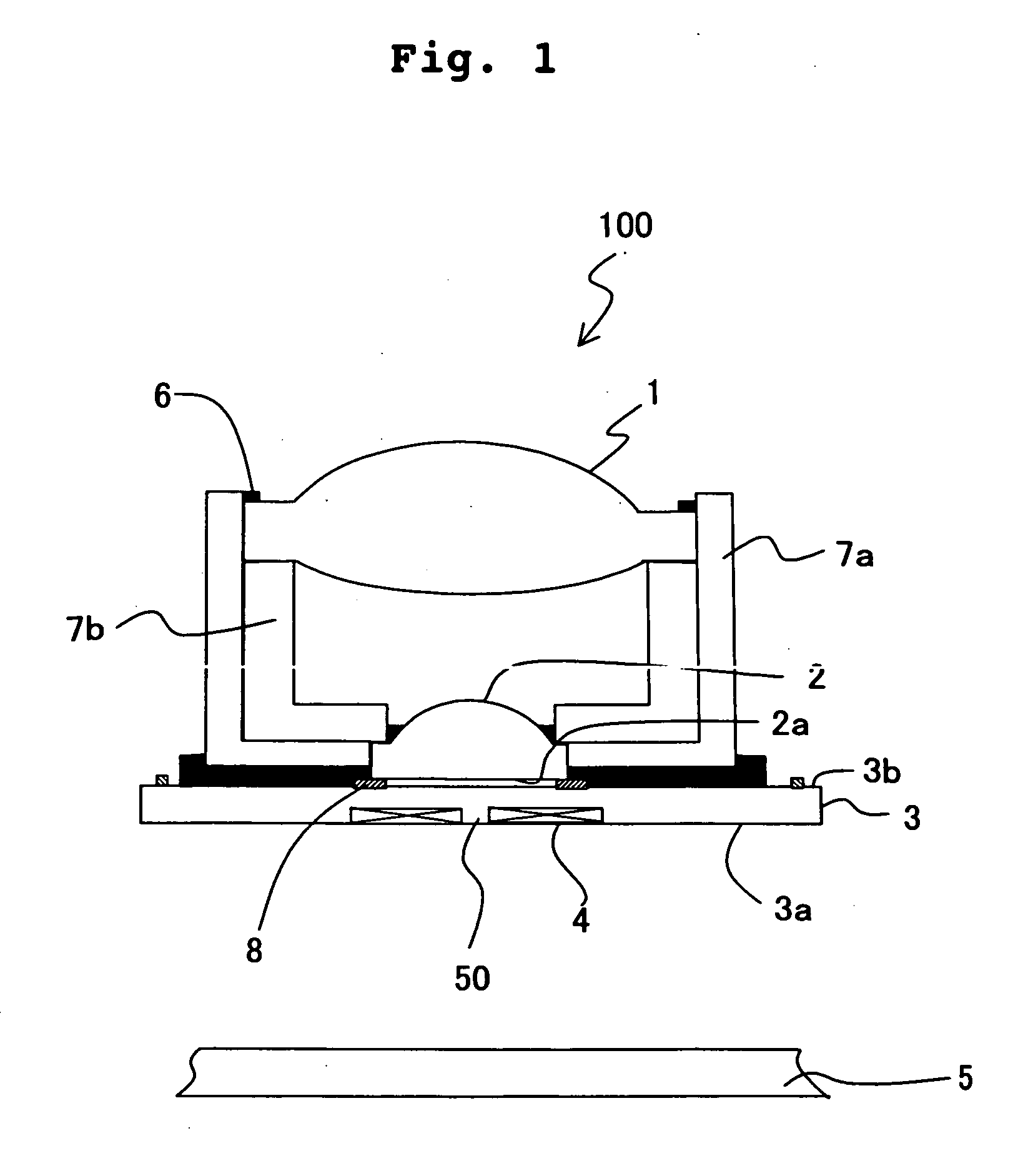

[0126] FIG. 21 shows a modified embodiment of the first embodiment. A magnetic coil substrate shown in FIG. 21 is produced in the same manner as in the first embodiment except that the film thickness of a heat sink layer 800 is thicker than that in the first embodiment, and the lower end of the heat sink layer 800 is disposed more closely to the disk side. The heat, which is generated from the magnetic coil 15 and which is transmitted to the heat sink layer, is readily released to the space between the disk and the substrate 3, because the heat sink layer 800 is disposed more closely to the disk side. Therefore, the heat-releasing effect of the heat sink layer is improved. The heat sink layer may further extend downwardly to make contact with the protective film 17. Alternatively, the heat sink layer may be exposed to the disk side without providing the protective film 17 partially. By doing so, the heat-releasing effect of the heat sink layer can be further improved.

seventh embodiment

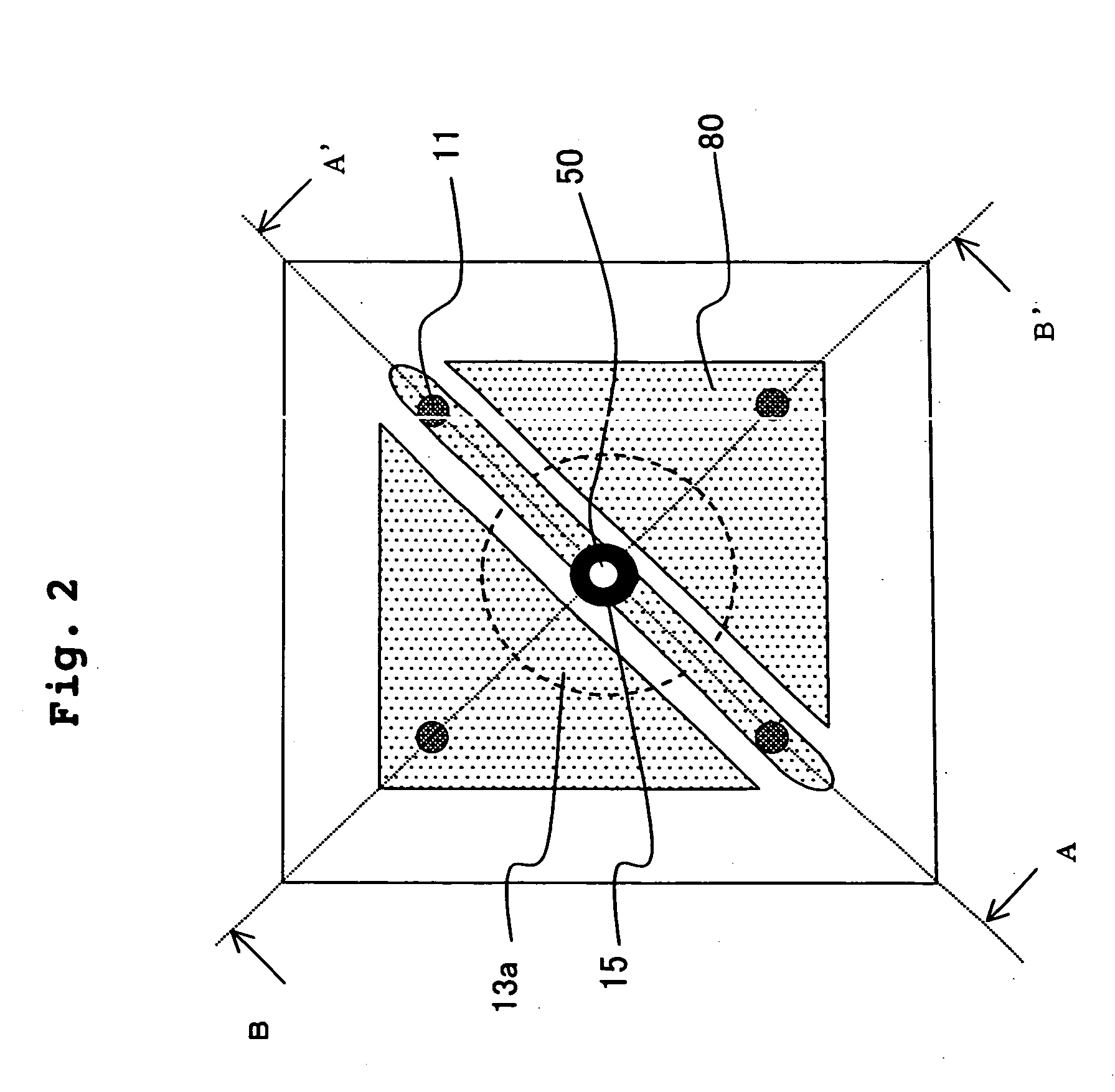

[0127] In this embodiment, a magnetic coil substrate was formed in the same manner as in the first embodiment except that a magnetic coil 600 was formed to have an elliptic configuration as shown in FIG. 26. A magneto-optical head was produced with the magnetic coil substrate. The elliptic magnetic coil can be formed with ease by exposing the photoresist to the light with an elliptic helical pattern as a photomask in the step for forming the coil shown in FIG. 6(d).

[0128] The reason why the magnetic coil 600 was formed to have the elliptic configuration is as follows. That is, it is necessary to perform the tracking for the disk when information is recorded or reproduced on the magneto-optical disk by using the magneto-optical head. The tracking is performed by operating a rotary actuator for supporting a head and a galvano-mirror provided for a fixed optical system (see FIG. 25) installed with a laser light source and a detector by the aid of an arm. The light beam, which is reflec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear velocity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electric power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com