Saccharide treated cellulose pulp sheets

a cellulose and cellulose technology, applied in the field of cellulose fibers, can solve the problems of difficult fiberization of fibers, difficult processing of binder coated fibers, and limited search for desirable treatment chemicals, and achieve the effects of low cost, superior densification and softness properties, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

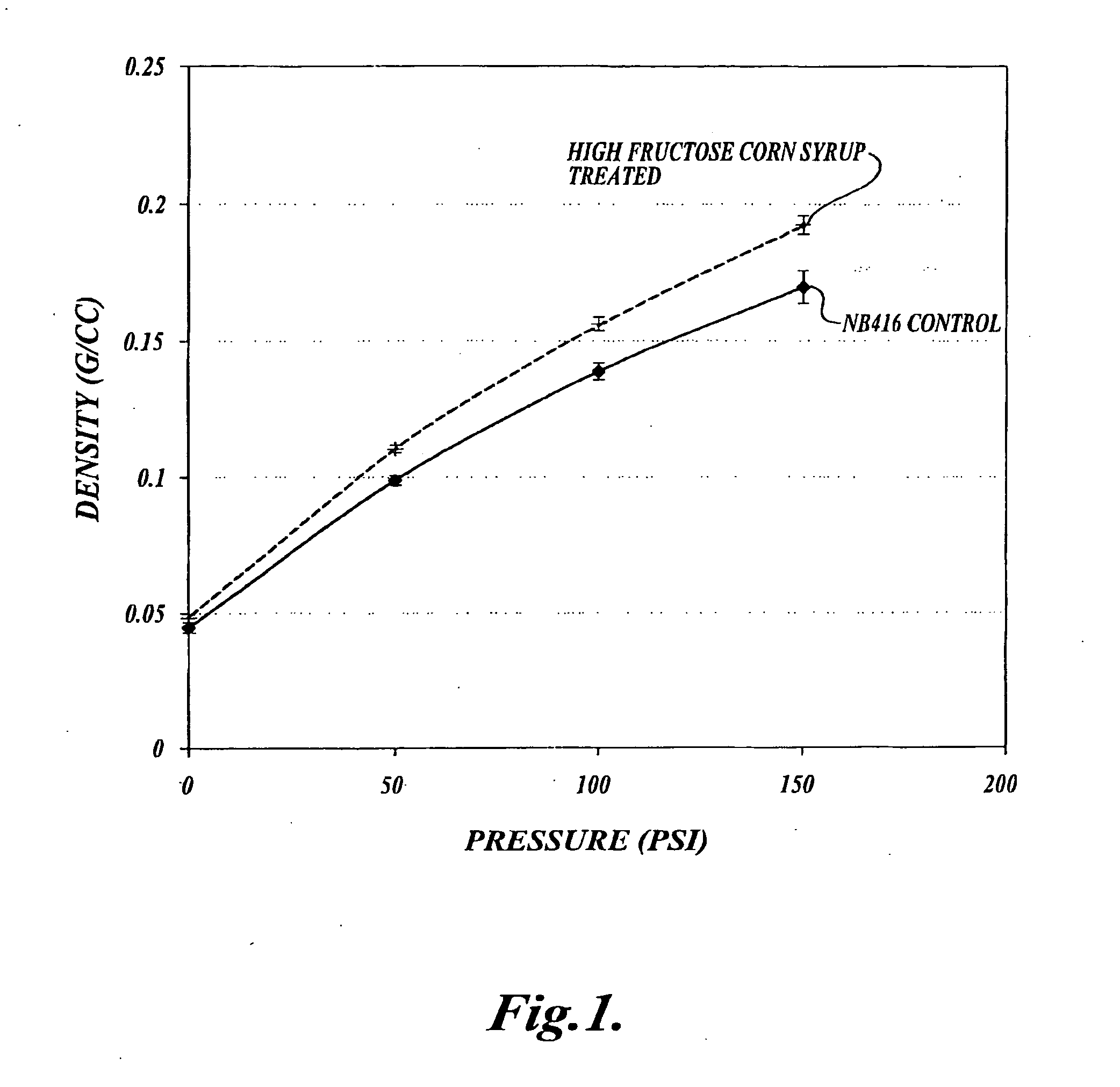

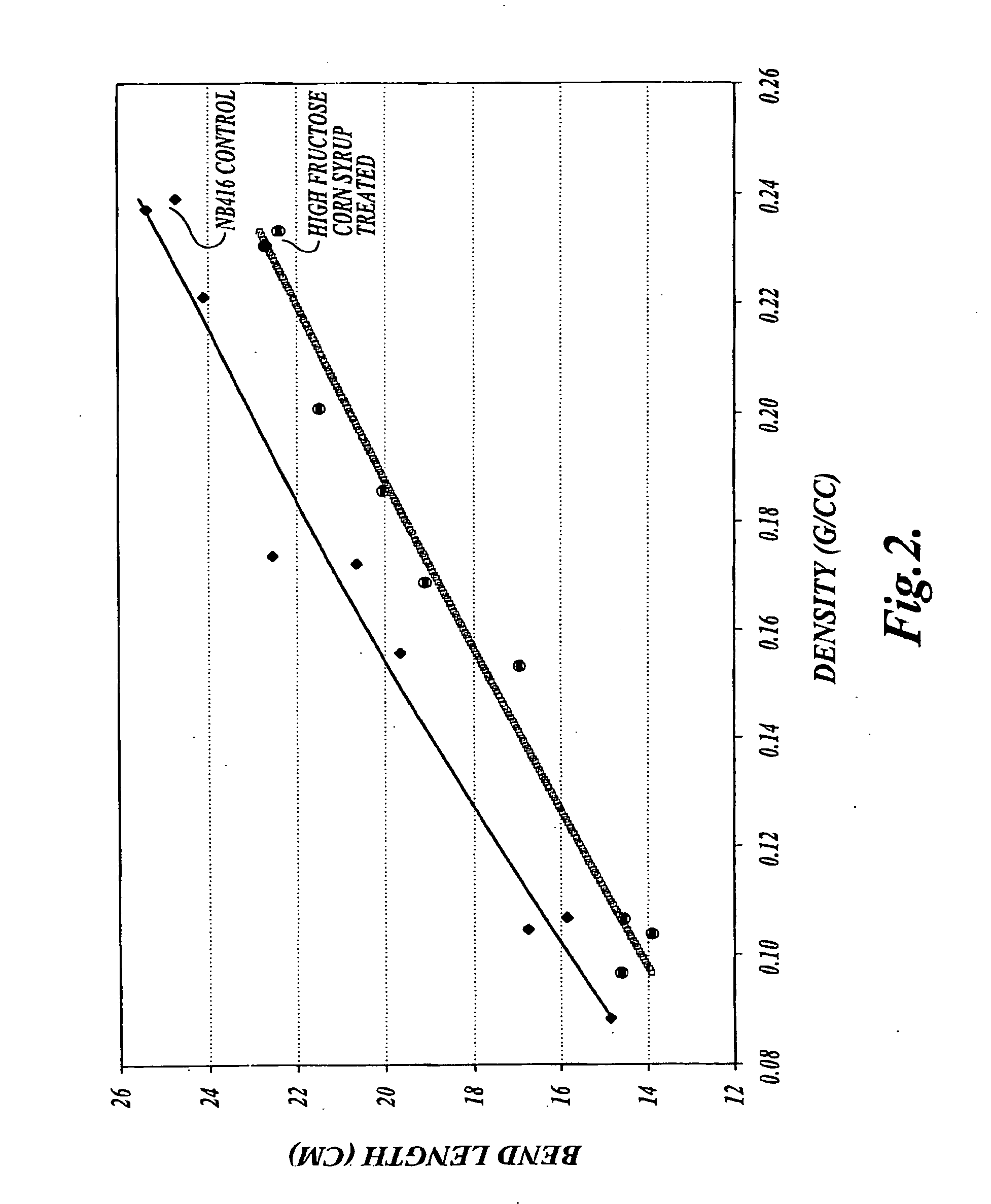

Preparation of High Fructose Corn Syrup Treated Cellulose Pulp

Southern Pine fluff in sheet form available from Weyerhaeuser Company under the designation NB 416 from New Bern, N.C. with a starting moisture content of 6% by weight (based on total sheet weight) was coated in a Black Brothers gravure-type roll coater with a solution of corn syrup. The gravure coater results in the application of a uniform coating of the corn syrup solution over one entire surface of the pulp sheet from where it is rapidly soaked up by the sheet. The corn syrup was a high fructose corn syrup available from Archer-Daniels Midland Company of Decatur, Ill. under the trademark CORN SWEET® 42. The corn syrup had a solids content of 71% with the balance being water. This corn syrup was diluted with water to a solid content of 54.5 wt. % based on total solution weight before its application to the wood pulp sheet. This 54.5 wt. % solution was applied to the wood pulp sheet at a rate of 15.5 parts solution to...

example 2

Preparation of High Fructose Corn Syrup Treated Cellulose Pulp Sheet Using Diluted Corn Syrup

The procedure in Example 1 was reproduced except that the CORN SWEET® 42 corn syrup was diluted to a solids content of 52.2 wt. % based on total solution weight using water. 10.58 parts of the corn syrup solution were added to 100 parts of the NB 416 wood pulp cellulose sheet. This resulted in a loading of active (on a dry basis) corn syrup solids of 5.88 wt. % based on the dry fiber content (or an equivalent 5.0 wt. % corn syrup solid based on the total final product weight). The final total moisture content of the wood pulp sheet treated with corn syrup was 10 wt. % based on the total final product weight. Knot yield after fiberization was 16% for the above sample.

example 3

Preparation of High Fructose Corn Syrup Treated Cellulose Pulp Sheet Treated With Heat

An additional sample of the corn syrup treated wood pulp of Example 1 was further evaluated on a Fitz Hammermill feeding an M&J continuous airlaid pad forming device. A portion of the corn syrup treated pulp sheet of Example 1 was first run as-is on the Fitz Hammermill. The resultant fiberized pulp was collected. The remaining portions of the treated pulp sheet were sealed inside plastic bags double layered to prevent moisture loss and heated for 24 hours at 150° F. in a laboratory oven. After heat treatment, the pulp sheet was allowed to cool back to room temperature while still in the plastic bags and was then fiberized on the Fitz Hammermill under the same conditions used for the non-heat-treated pulp. Both heated and non-heated pulps were tested for knot content by the sonic method described above. The knot content of the two samples was similar; however, the physical appearance of the pulp w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com