Ornamental beads and method of manufacture

a technology of ornamental beads and manufacturing methods, applied in the field of ornamental beads, can solve the problems of unsatisfactory or conformity, affecting the design of the ornamental beads, and allowing consumers to customize or individualize the designs. to avoid any damage to the bead and its design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

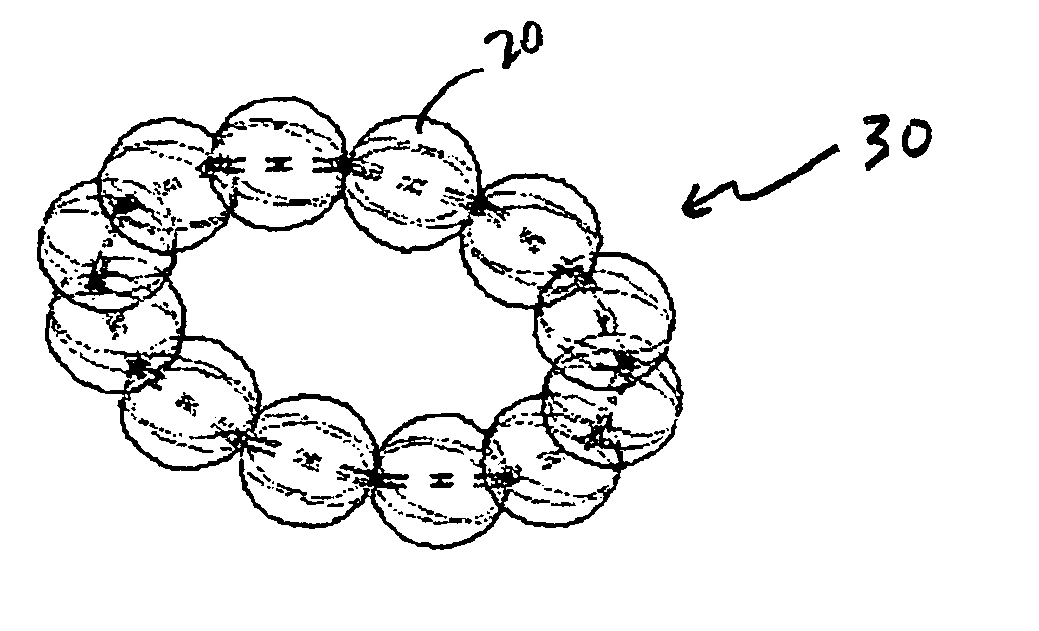

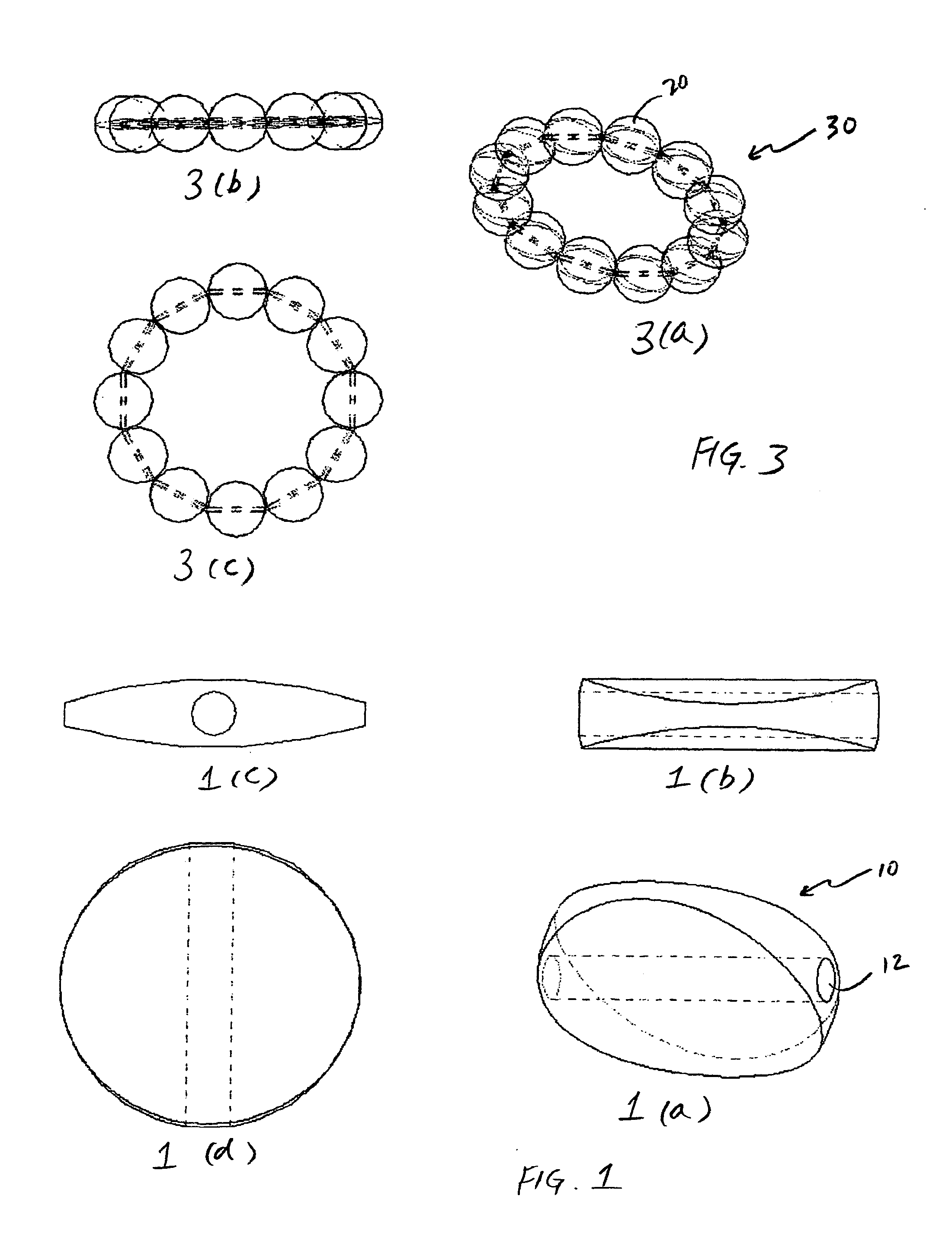

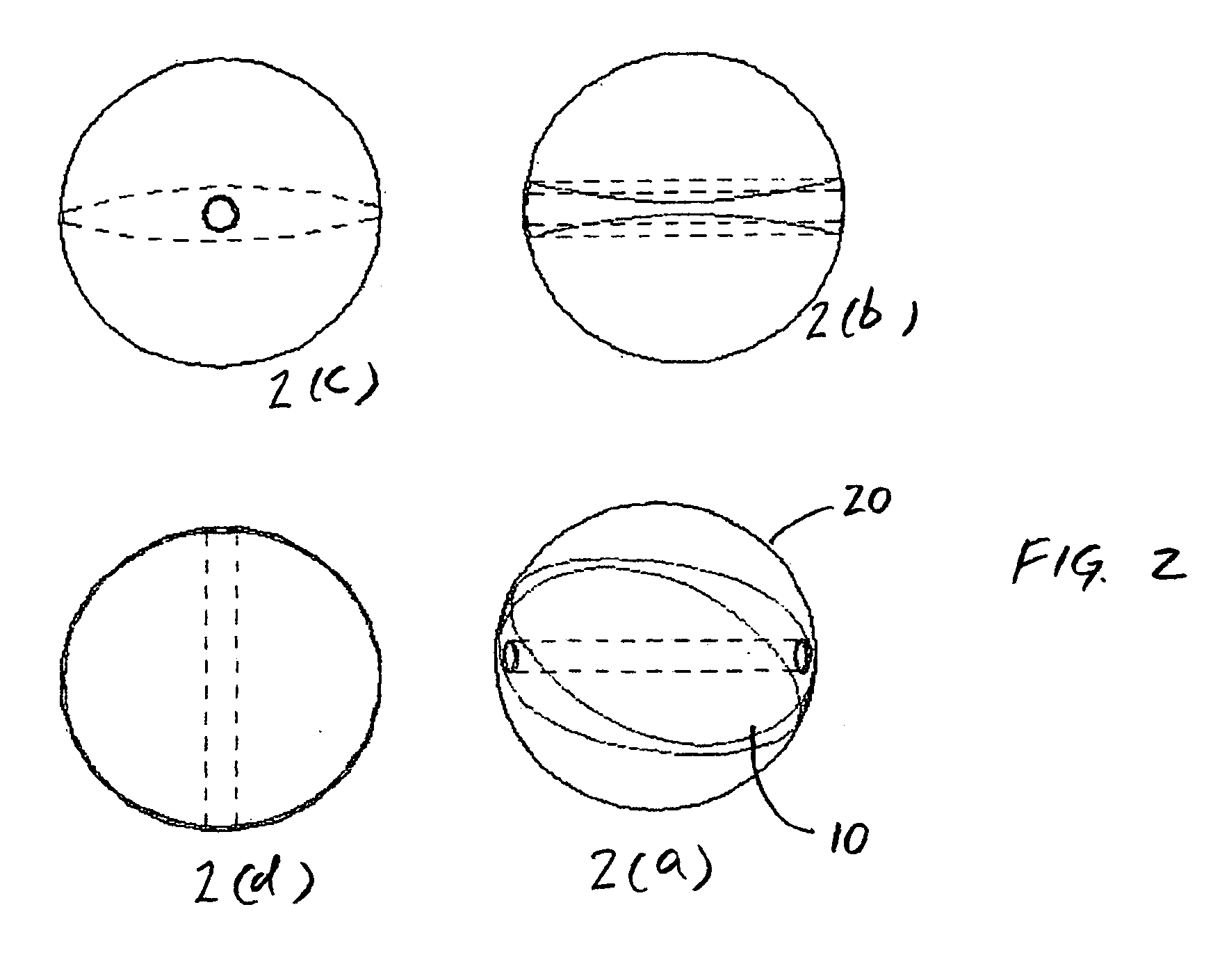

[0014] A set of ornamental beads and the method of making the same is disclosed. In the description that follows, for simplicity purposes, references will be made to a bracelet, or a necklace, of beads. However, it should be apparent to those skilled in the art that the present invention is applicable to any set of decorative beads, which can be used to personalize a person's belongings, such as one's hair, clothing, cell phone, PDA, luggage, sports gear or car. FIGS. 1 (a)-(d) are simplified diagrams illustrating the inner disk 10, which is preferably made of plastic material. FIG. 1(a) is a perspective view of the inner disk with a through hole 12 already formed along its diameter. FIG. 1(b) is a front view of the inner disk. FIG. 1(c) is a side view of the inner disk 10, and a ninety-degree horizontal rotation from the front view shown by FIG. 1(b). FIG. 1(d) is a top or bottom view of the inner disk 10. Note that the profile of the inner disk 10 is gradually thinning from the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com