Preparation and use of solidified oils

a technology of solidified oils and solidified oil, which is applied in the direction of aerosol delivery, drug compositions, metabolic disorders, etc., can solve the problems of poor patient compliance, high dose therapy with purified vitamin e, or with substances such as wheat germ oil or fish oil, and achieve the effect of improving patient complian

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

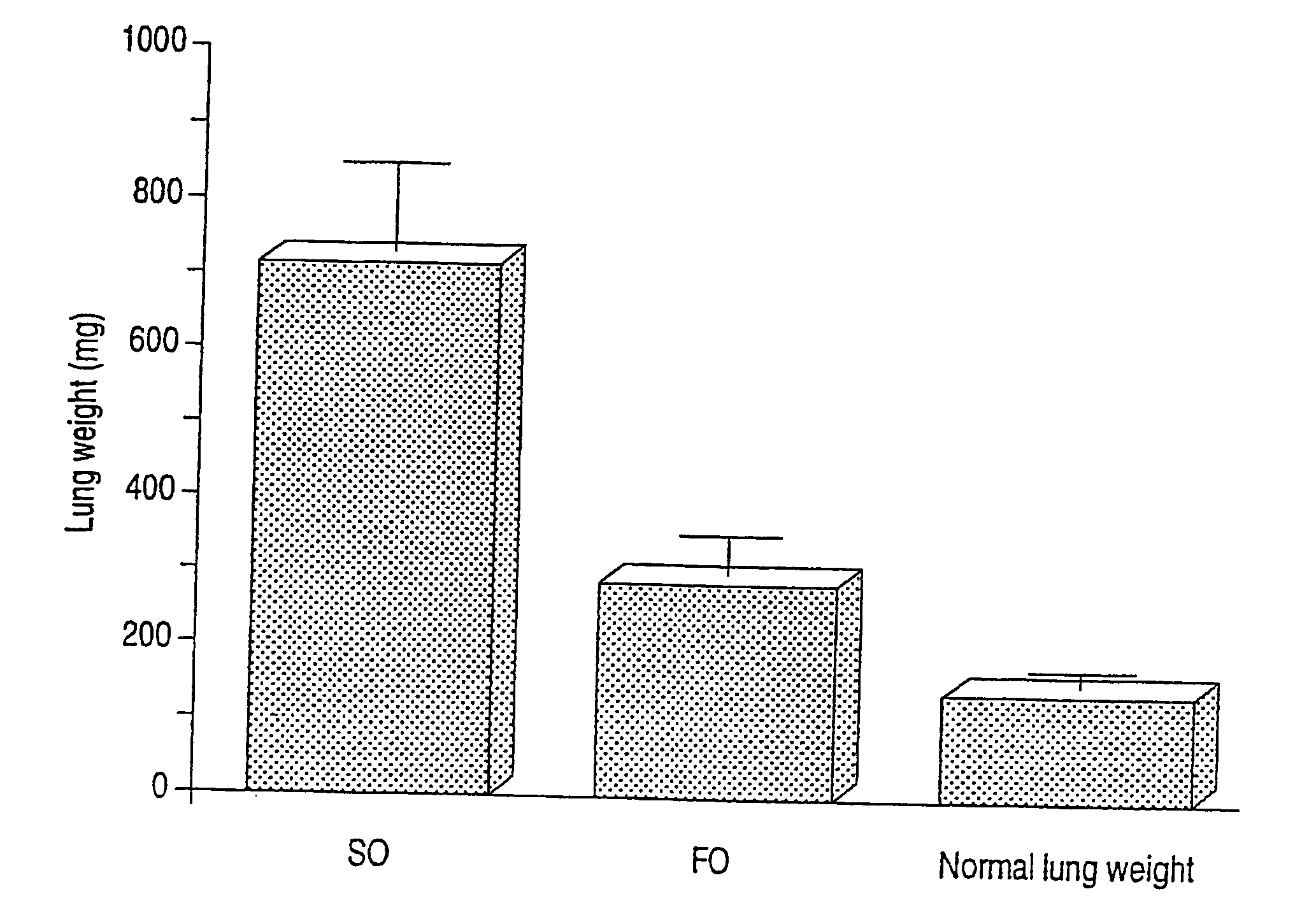

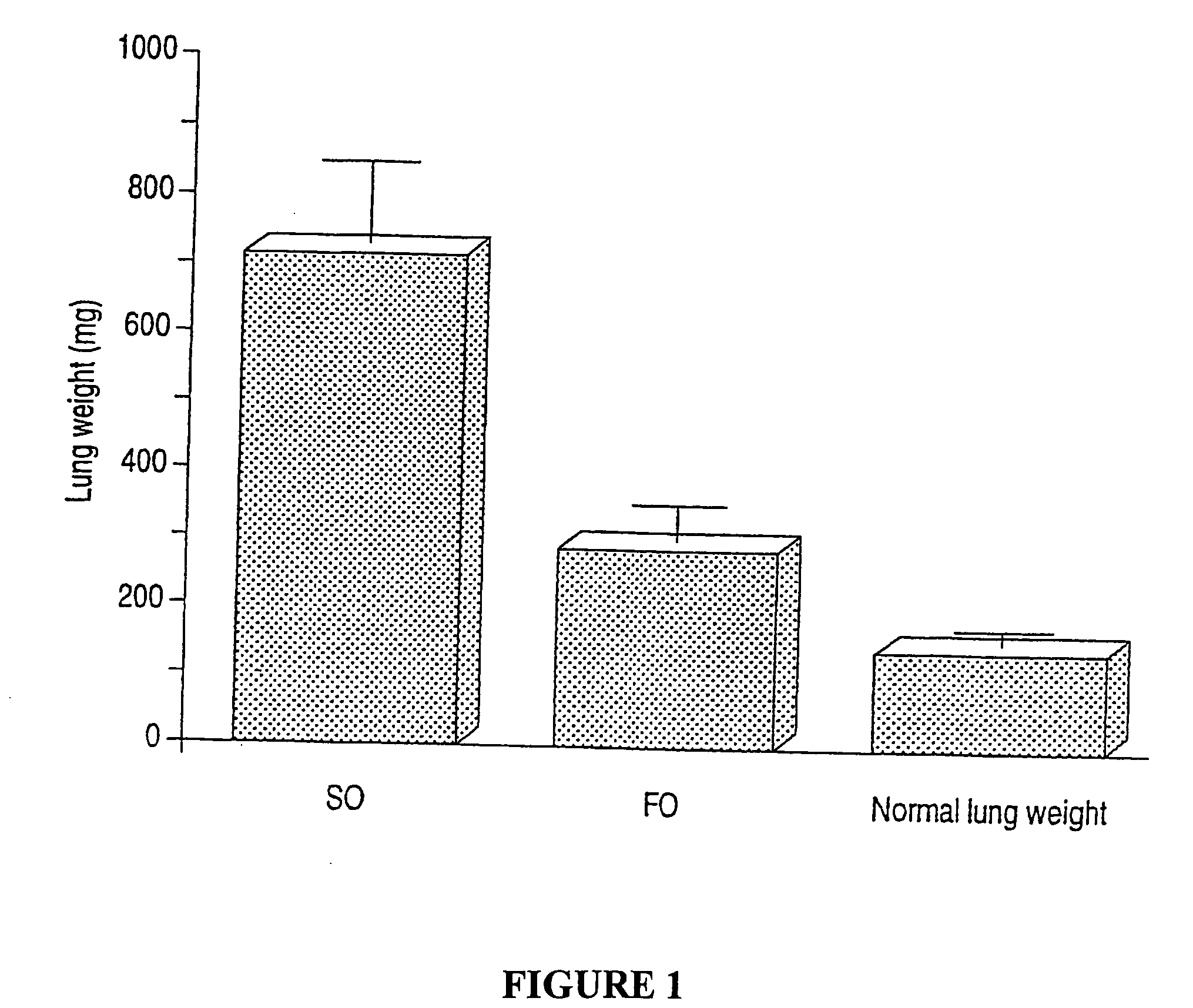

Image

Examples

example 1

Solidification of Fish Oil by Bee Wax

[0052] Eighty grams of bee wax (Colmeia do Mato Grosso, Mato Grosso, Brasil) was warmed to 80° C. and mixed, under a nitrogen atmosphere, with 400 grams fish oil (EPAX7010 triglycerides, Pronova Biocare a.s. Sandeford, Norway). The mixture was mechanically stirred until a homogeneous consistency was obtained. Upon cooling to 25° C., the mixture solidified to form a homogeneous semi-solid paste. The weight percent of the fish oil in this mixture is 83%. This material was subsequently employed in Examples 5 and 6.

example 2

Solidification of Soybean Oil by Bee Wax

[0053] Eighty grams of bee wax (Colmeia do Mato Grosso, Mato Grosso, Brasil) was warmed to 80° C. and mixed, under a nitrogen atmosphere, with 400 grams soybean oil (from the market). The mixture was mechanically stirred until a homogeneous consistency was obtained. Upon cooling to 25° C., the mixture solidified to form a homogenous semi-solid paste. The weight percent of the oil in this mixture is 80%. This material was subsequently employed as control in Example 5.

example 3

Solidification of Soybean Oil by Bee Wax

[0054] Eighty grams of bee wax (Colmeia do Mato Grosso, Mato Grosso, Brasil) was warmed to 80° C. and mixed, under a nitrogen atmosphere with 400 grams olive oil (from the market). The mixture was mechanically stirred until a homogeneous consistency was obtained. Upon cooling to 25° C., the mixture solidified to form a homogeneous semi-solid paste. The weight percent of the oil in this mixture is 80%. This material was subsequently employed as control in Example 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com