Plating system with compression drill guide

a drilling guide and drill guide technology, applied in the field of bone fixation system, can solve the problems of affecting the accuracy of the fixation system, the risk of tissue damage, and the size of the vertebral bone available for the fixation of the screw within the plate hole,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

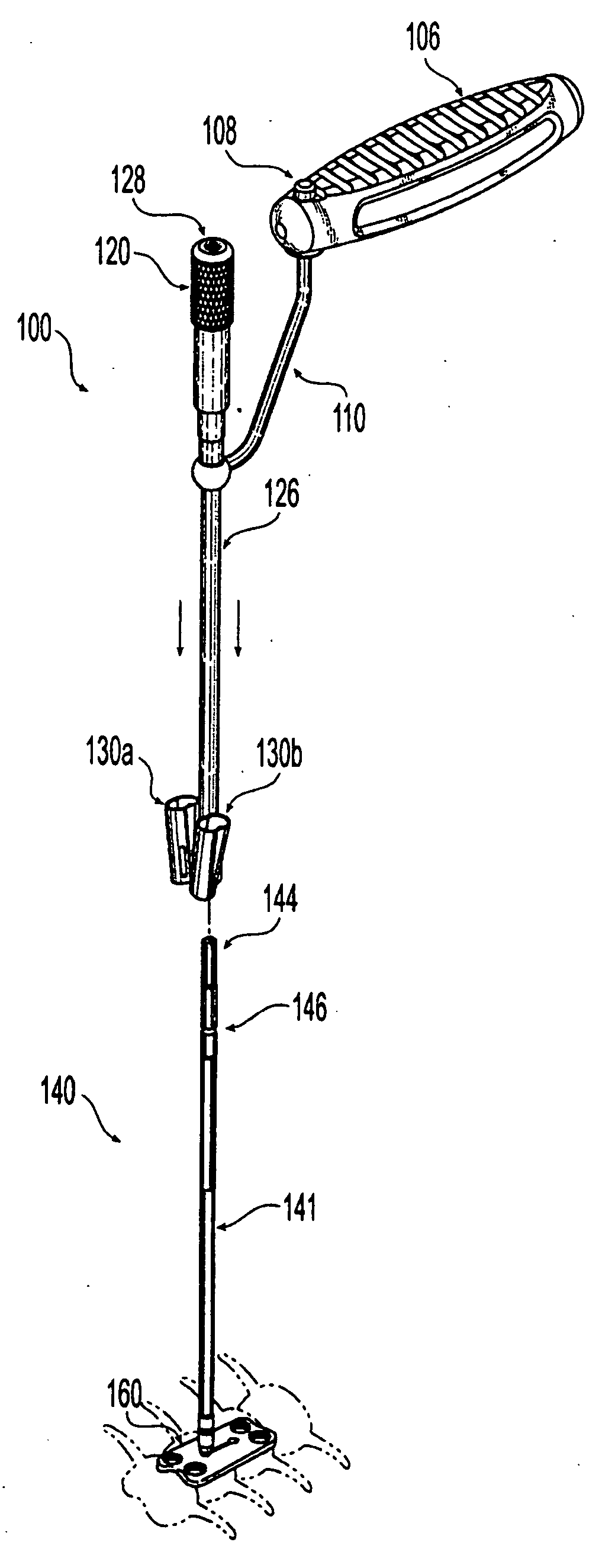

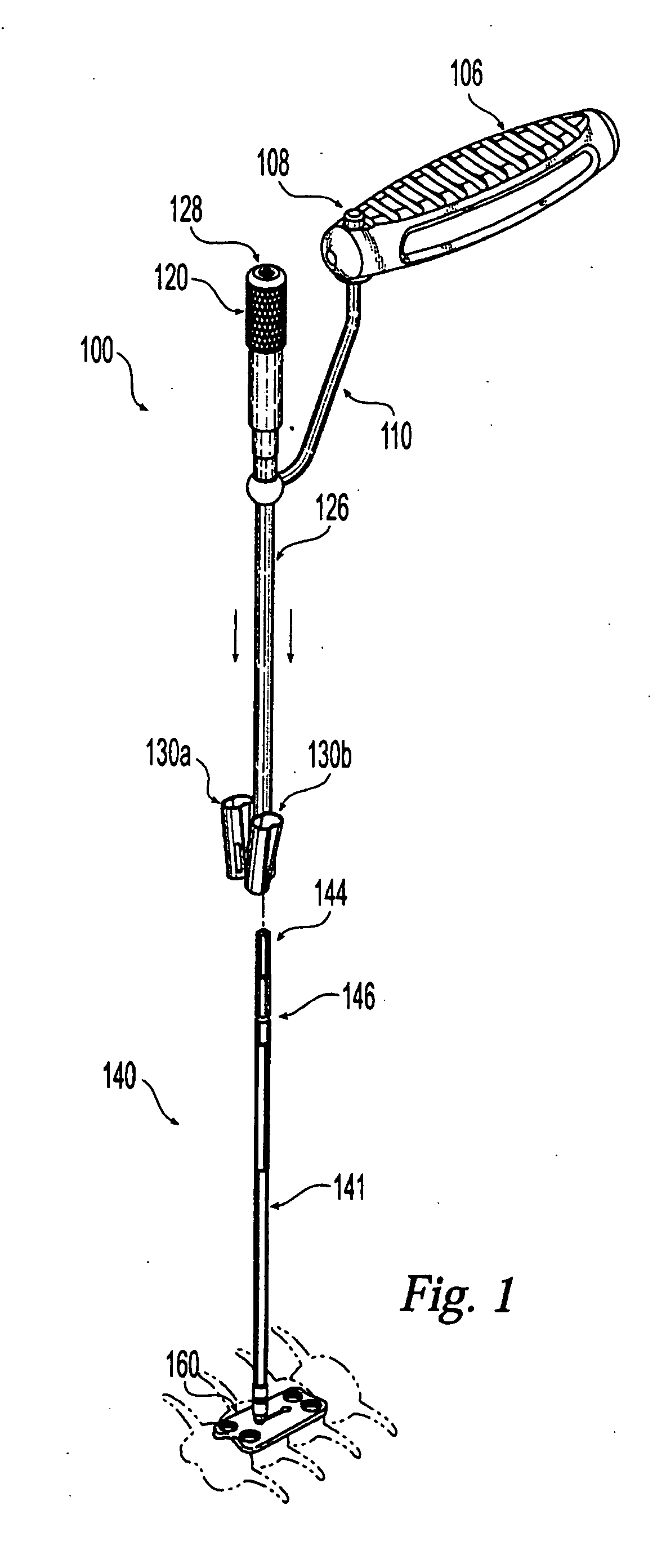

[0054] Referring to FIG. 1, there is shown an exemplary double barrel drill guide assembly 100 and plate holder 140, which are adapted for use with a slotted cervical spine locking bone plate 160. While the bone plate, and plate holder and drill guide assembly are shown and described as a cervical plate for use in the cervical region of the spine, it will be appreciated that the bone plate features are applicable to other bone plates and that the drill guide assembly and plate holder are also usable with other bone plates. Assembly 100 includes a handle member 106, an offset handle stem 110, release sleeve 120, outer stem 126, and drill guiding barrels 130a and 130b. Handle member 106 of drill guide assembly 100 can be incrementally swiveled by pressing and holding button cam 108. Releasing the button cam 108 locks handle 106 in place with relation to offset handle stem 110.

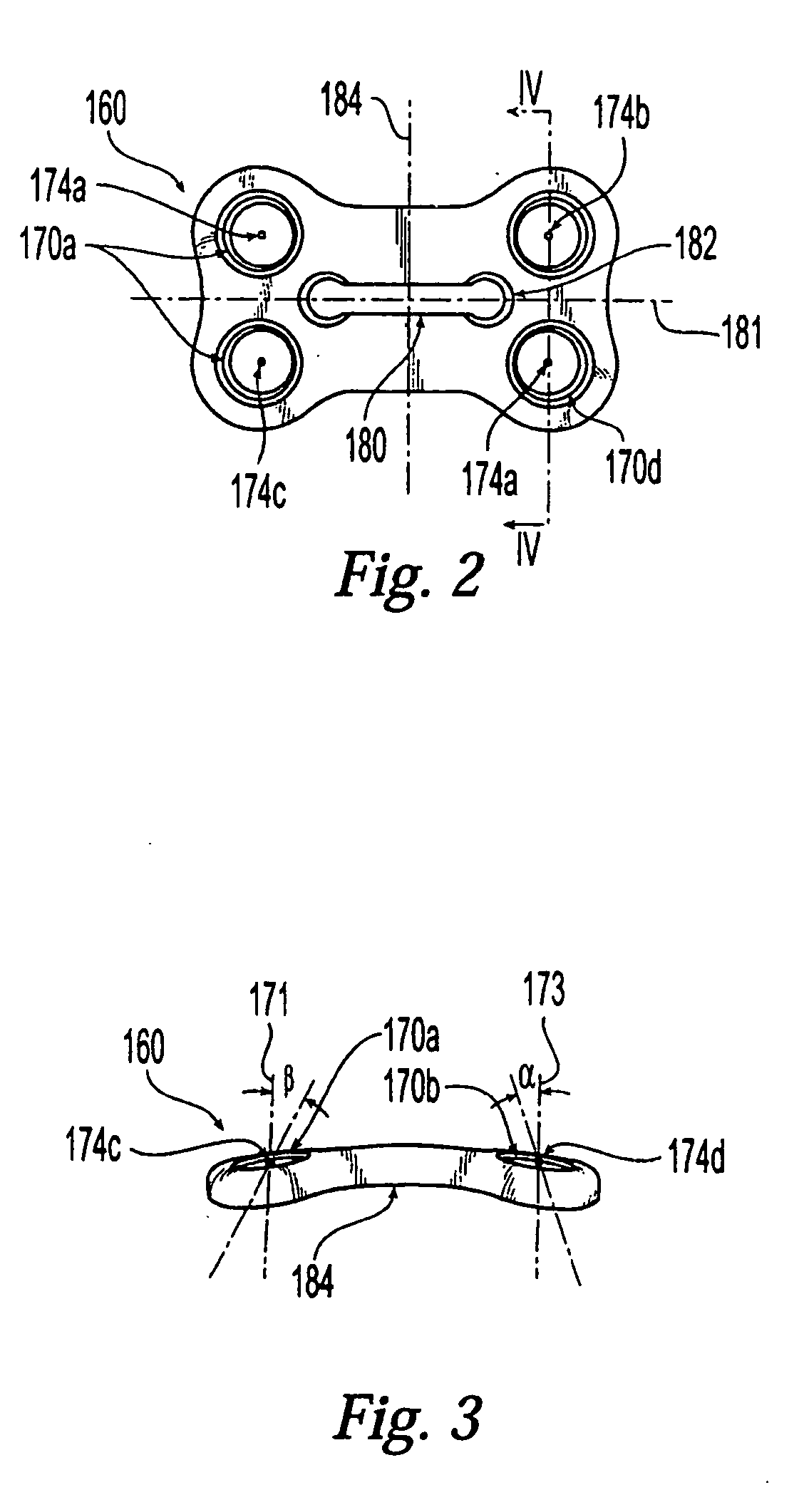

[0055] With reference to FIG. 2, cervical spine locking bone plate 160 is roughly dog-bone shaped with two pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com