Stand up bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0145] Detailed descriptions of the preferred embodiments are provided herein. The general concept of each embodiment is that a standup bag formed from flexible sheet material and has a substantially flat configuration becomes rigid when filled with a flowable substance. The pressure exerted by the flowable substance on the sheet material causes the bag to become self-standing even when partially filled. It is to be understood, however, that the present invention may be embodied in various forms. Therefore, specific details disclosed herein are not to be interpreted as limiting, but rather as a basis for the claims and as a representative for teaching one skilled in the art to employ the present invention in virtually any appropriately detailed system, structure or manner.

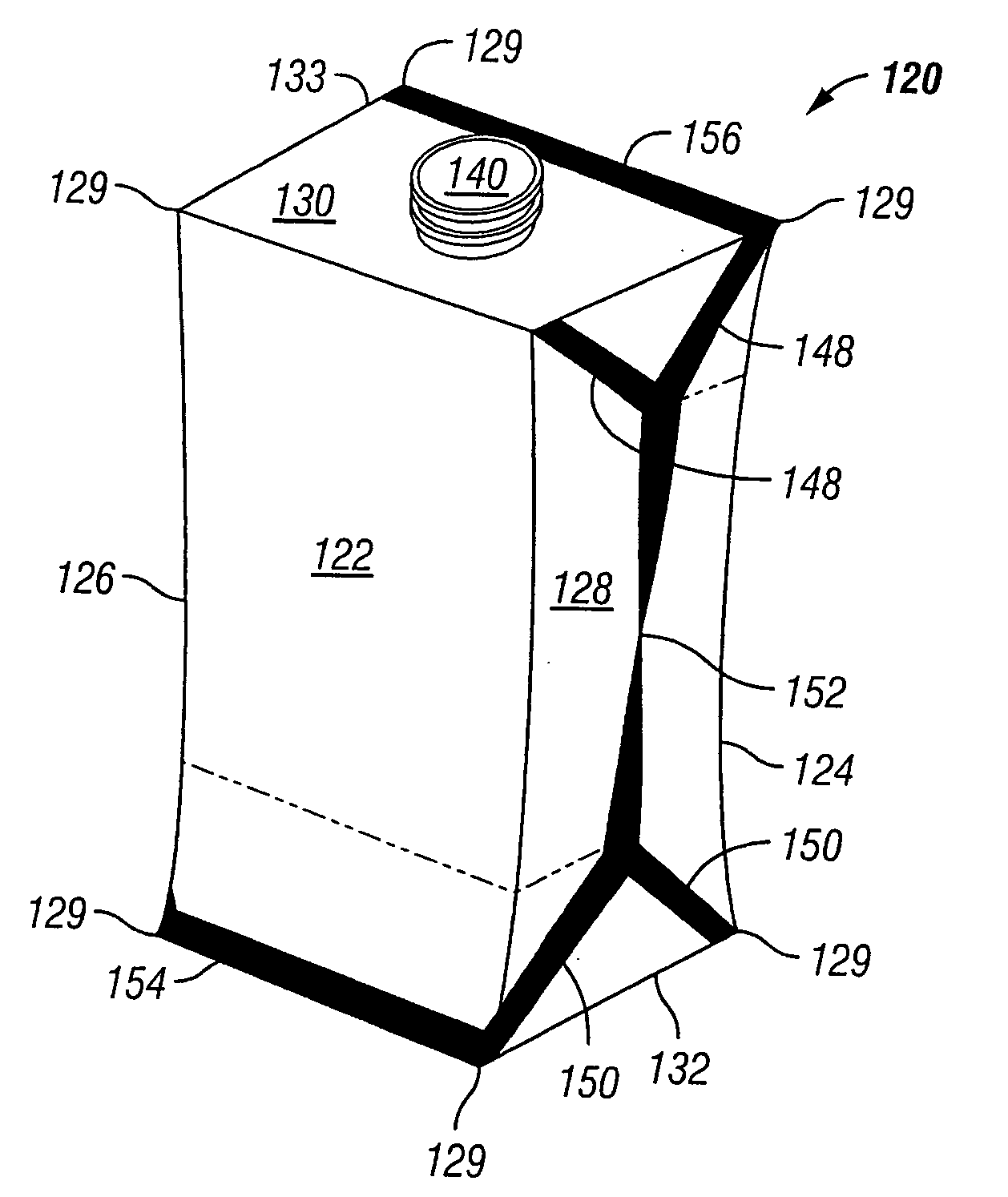

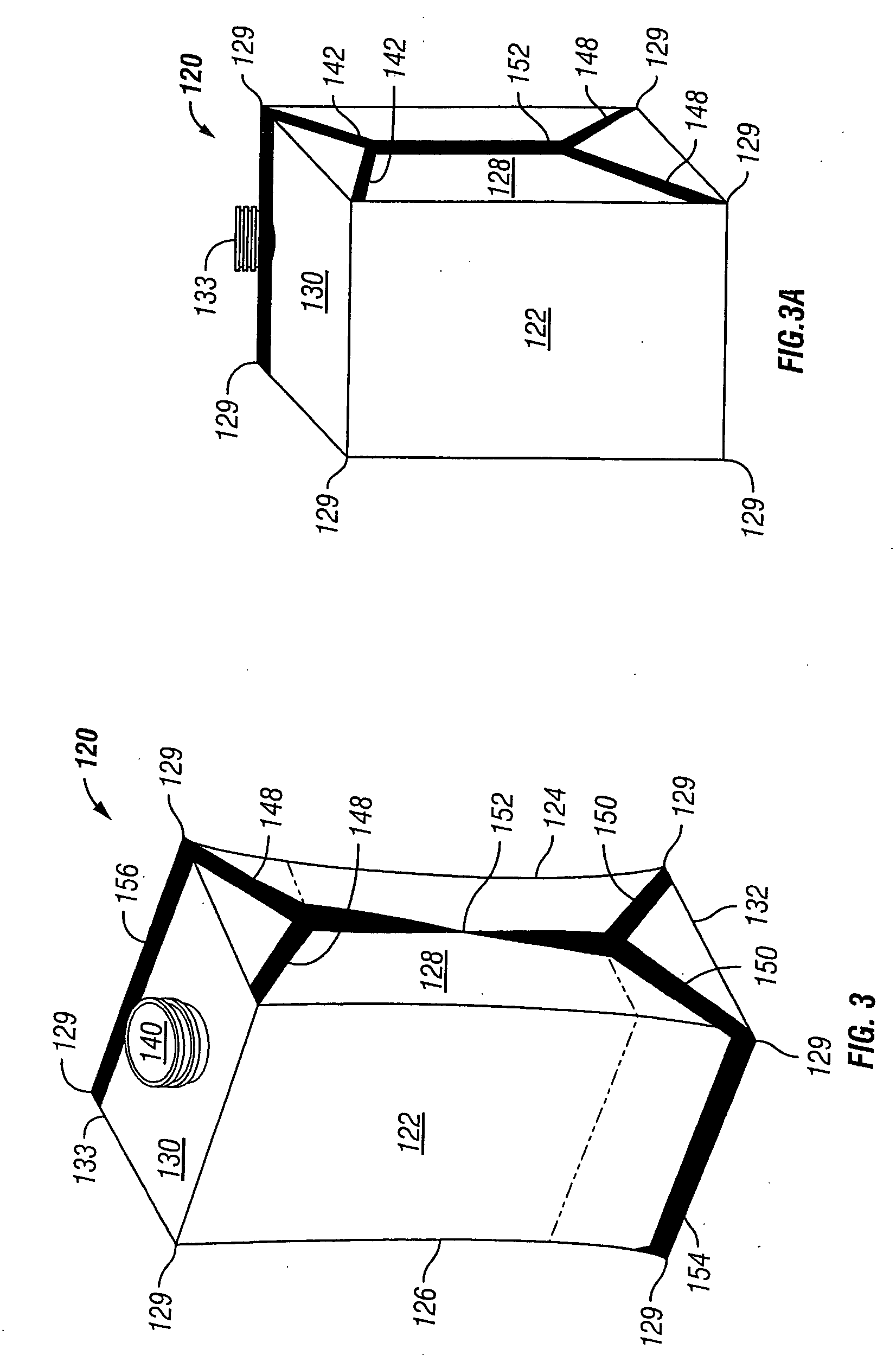

[0146] Referring to FIGS. 3-9, a standup bag 120 of the present invention is illustrated. The standup bag 120 has a front wall 122, a rear wall 124, side walls 126, 128, a top wall 130, and a bottom wall 132 to de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com