Rotational speed adjustment mechanism of a pneumatic tool

a technology of rotating speed adjustment and pneumatic tools, which is applied in the field of pneumatic tools, can solve the problems of air pressure, difficult to control the precision of the valve stem, and difficulty in manufacturing and processing specially shaped valve stems, and achieves the effects of high precision, simplified rotating speed adjustment mechanisms, and easy manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

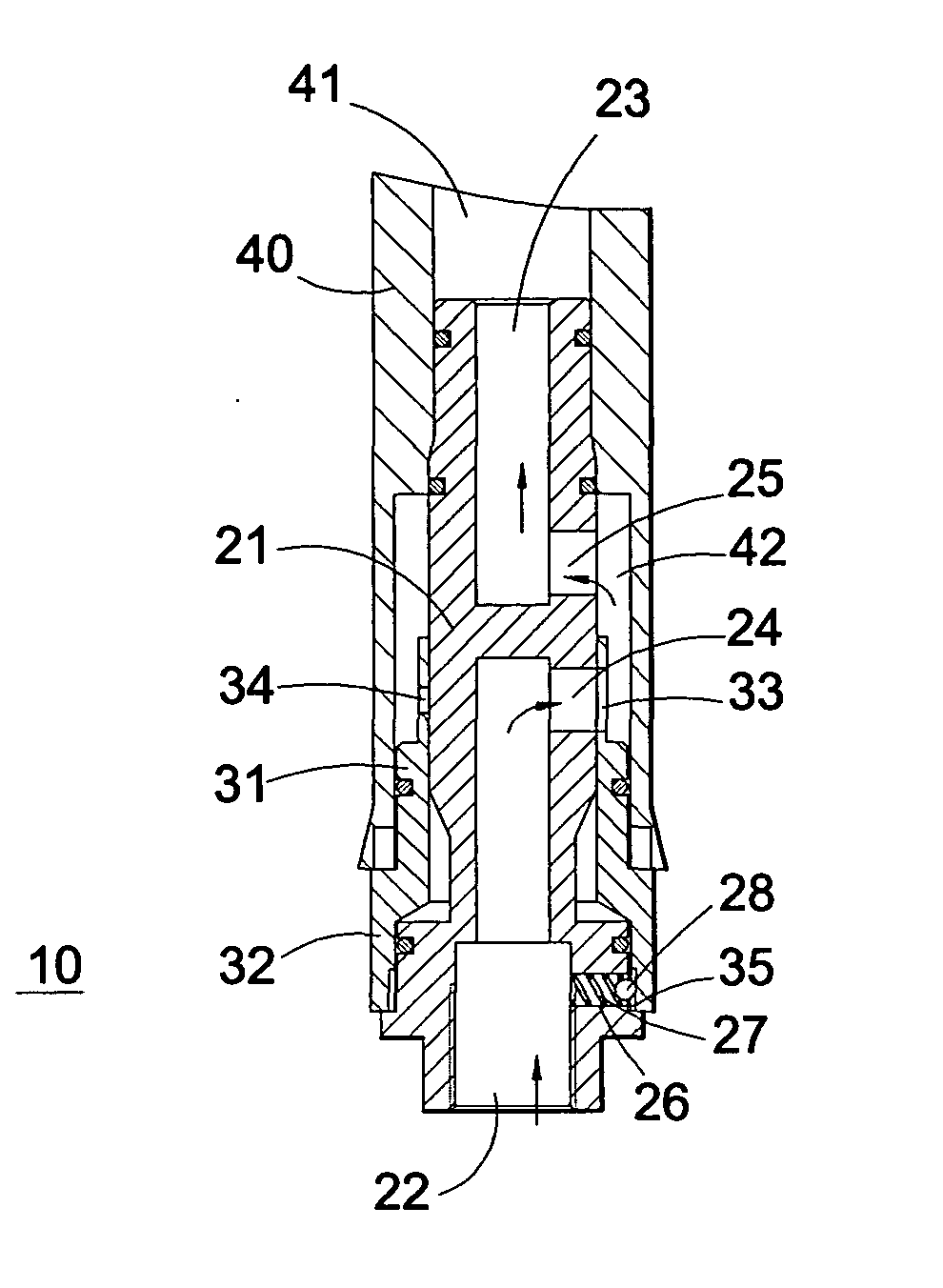

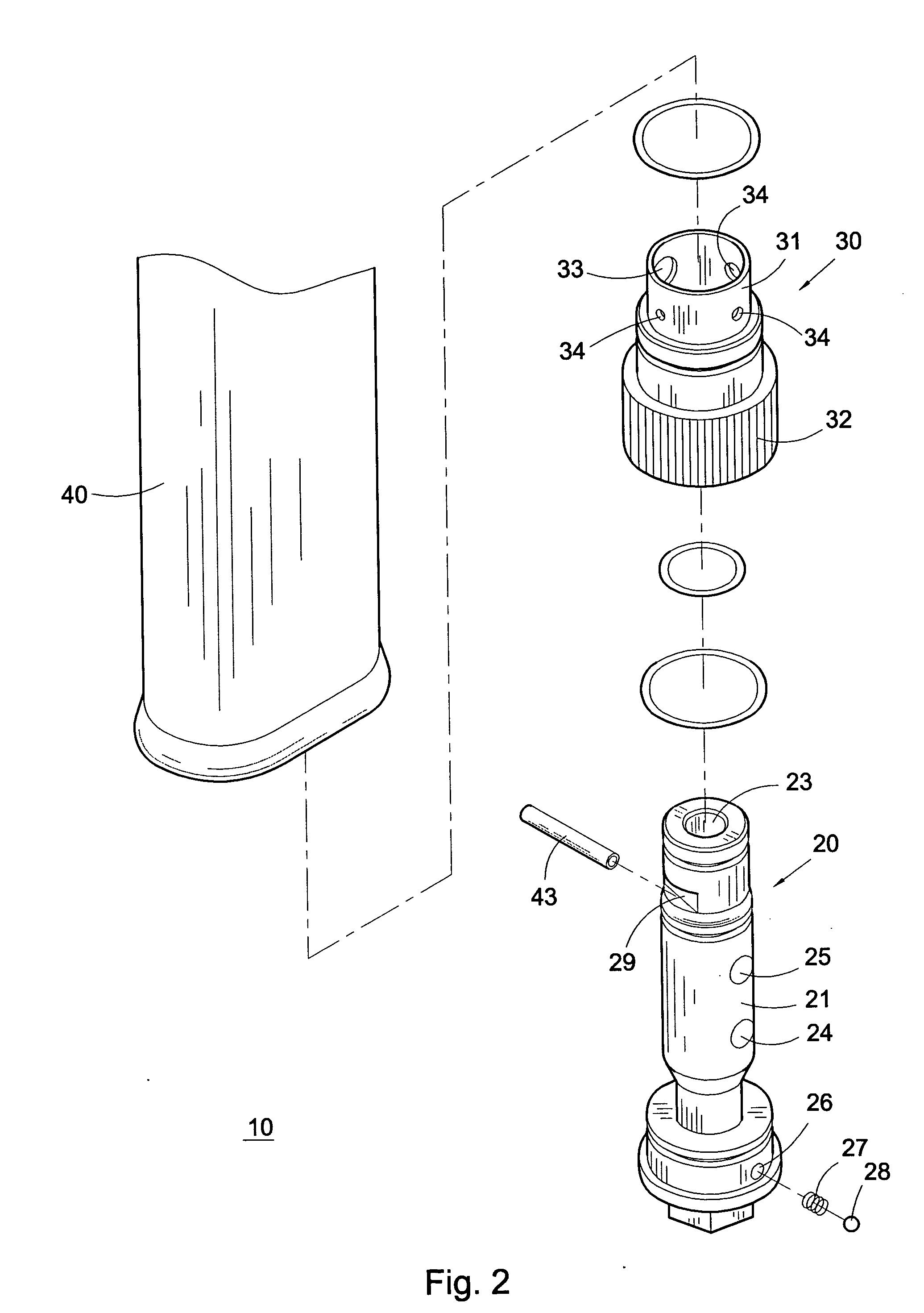

[0013] Please refer to FIGS. 1 to 5. The rotational speed adjustment mechanism 10 of the present invention includes an intake member 20, a speed adjustment valve 30 and a case 40.

[0014] The intake member 20 has an upright cylindrical body section 21 with a certain length. An intake 22 upward axially extends from the bottom end of the body section 21 by a certain depth. An exhaust port 23 downward axially extends from the top end of the body section 21 by a certain depth. The inner ends of the intake 22 and the exhaust port 23 are separated without communicating with each other. A lateral outlet 24 perpendicularly extends from one side of the inner end of the intake 22 through the wall of the body section. A lateral inlet 25 perpendicularly extends from one side of the inner end of the exhaust port 23 through the wall of the body section. The lateral outlet 24 and the lateral inlet 25 are parallel to each other, whereby the intake 22 and the exhaust port 23 are communicated with eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com