Coffee press

a coffee press and coffee technology, applied in the field of coffee press, can solve the problems of insufficient observation of the brew color, insufficient container, and inability to adequately observe the status of the beverage, and achieve the effect of improving the openable handle structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

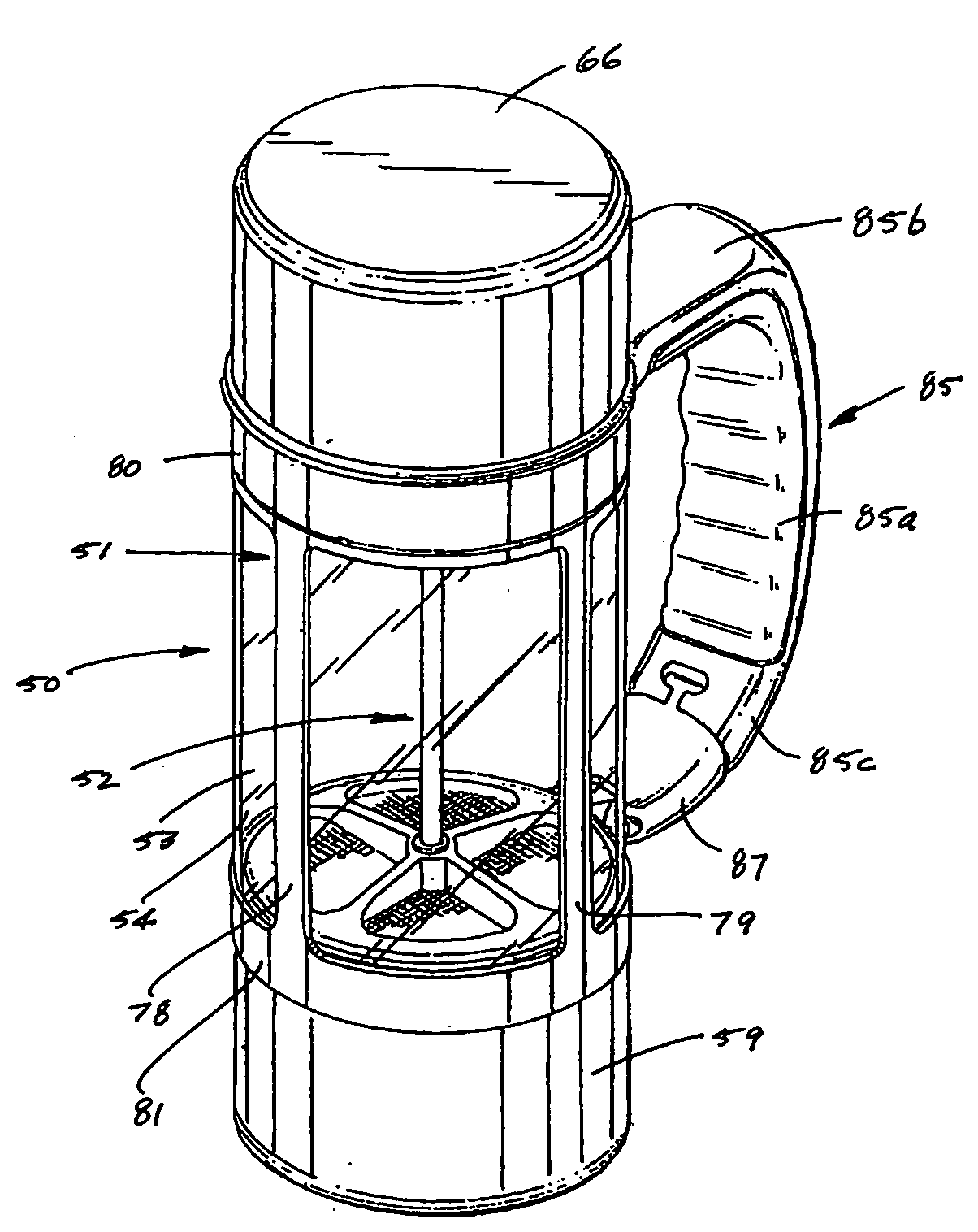

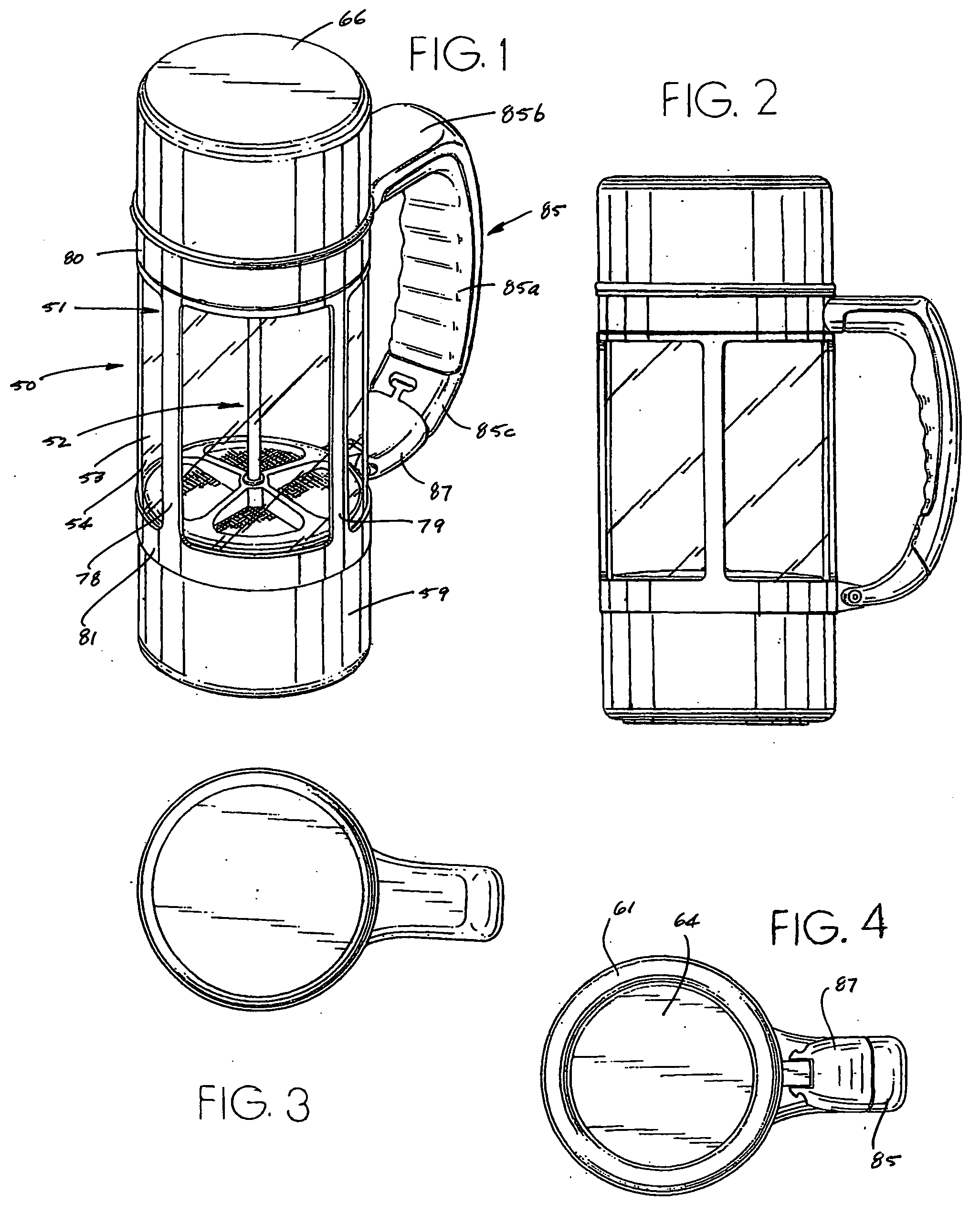

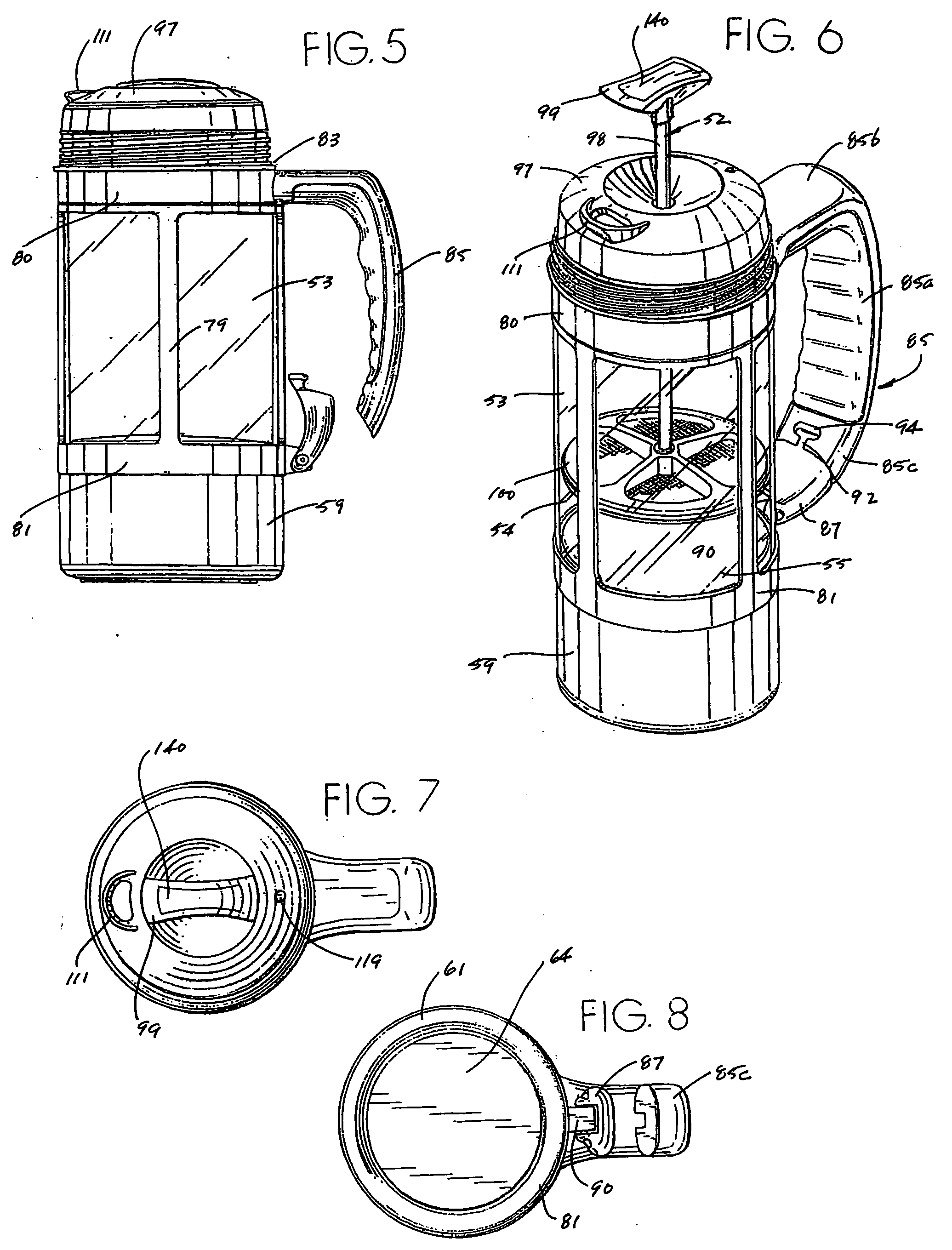

[0045] Referring to the Figures, there is seen an embodiment 50 of a coffee press of the present invention. The press 50 includes a housing or container assembly 51 and a plunger assembly 52. The container or housing assembly 51 comprises a cylindrical vessel 53 having generally cylindrical side walls 54, a closed bottom 55, and an open top mouth 56 whose exterior, adjacent lip regions 57 are threaded. The vessel 53 is preferably comprised of a unitarily molded, transparent molded plastic. Various plastics are suitable and preferably are impact resistant and also heat resistant both for purposes of holding heated aqueous liquids, like coffee or tea, and for purposes of washing the press 50 in an automatic dishwasher or the like. Examples of suitable plastics include polycarbonates, various polyacrylics, certain styrenic polymers, and the like, as those skilled in the art will readily appreciate.

[0046] The base or lower portion of the vessel 53 is associated with an overfitting, uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com