Temperature controlled frozen food dispenser

a technology of frozen food dispenser and temperature control, which is applied in the field of dispensing, can solve the problems of unnecessarily complex and expensive equipment, complex apparatus used, and the disclosed apparatus for determining the weight of the articles to be dispensed does not provide highly accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

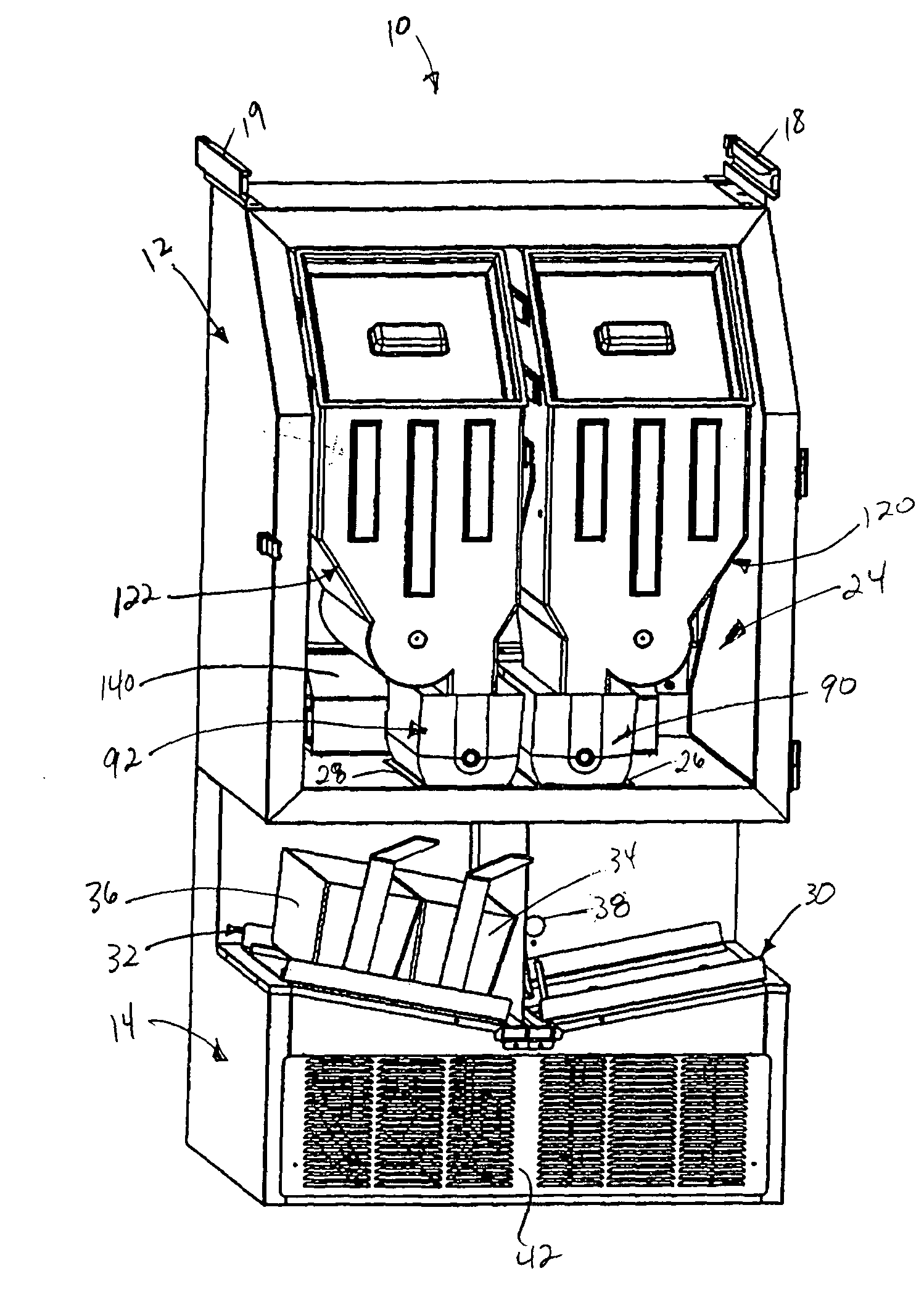

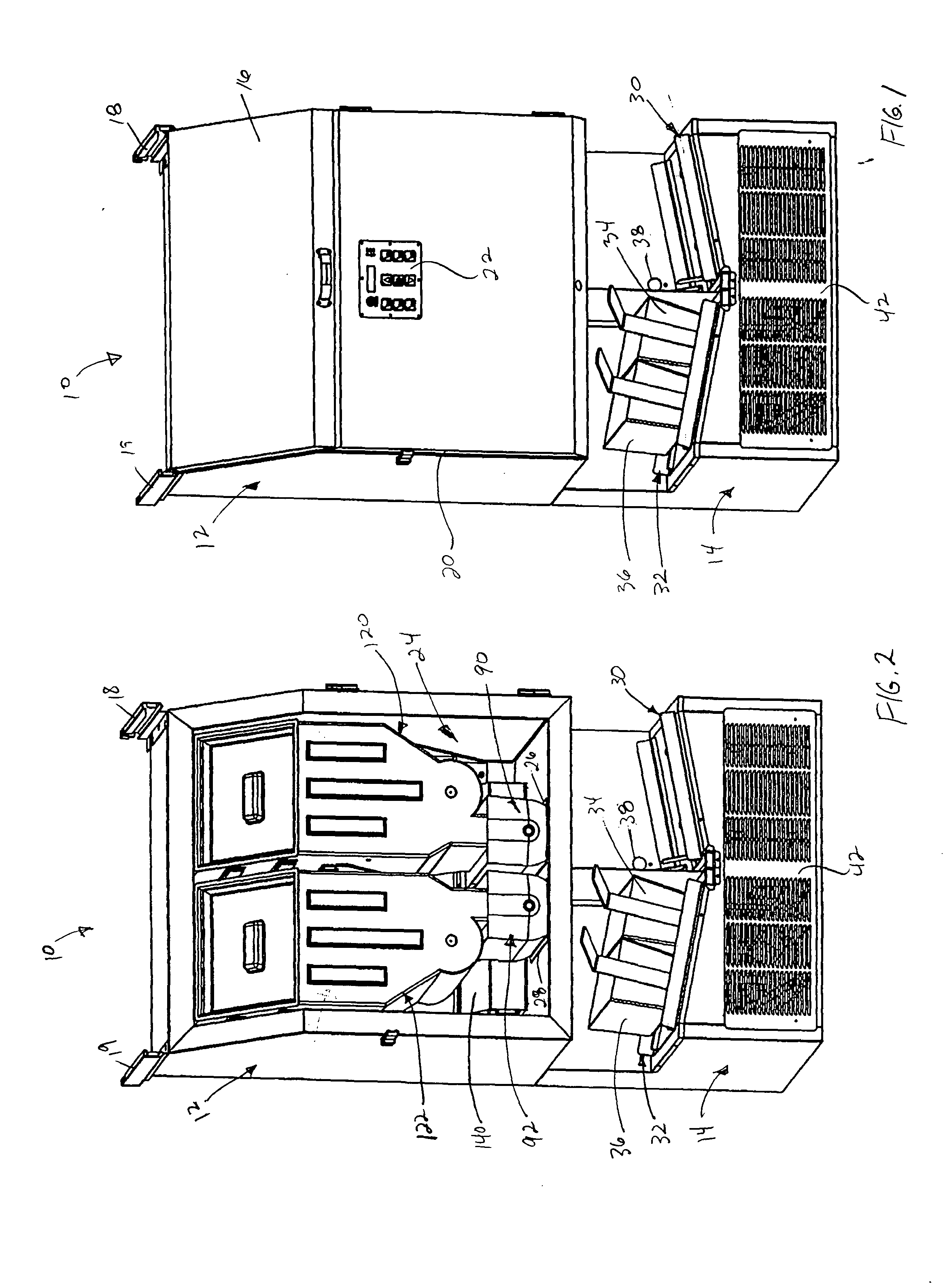

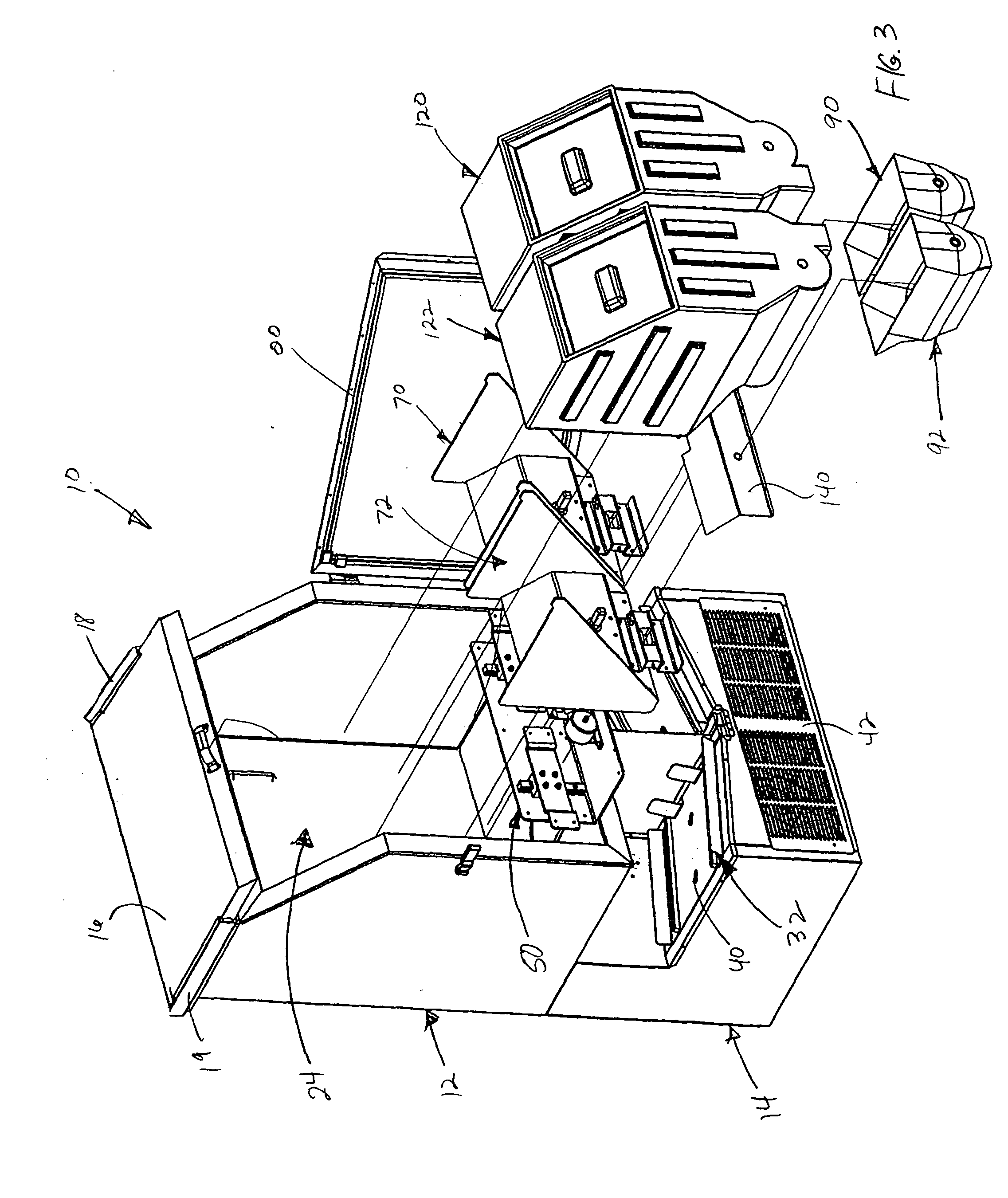

[0032] The present invention provides for a method and apparatus for dispensing food articles and controlling the temperature of the food articles held in the apparatus. The invention also provides for a method and apparatus for weighing the food articles held in the apparatus and controlling the amount of food articles dispensed based on the weighed amount of food articles.

[0033] The food article receiving container that receives dispensed food articles may include, for example, a basket, tray, a cooking sheet, or other kitchen utensil / container that is suitable for receiving the dispensed food articles. For ease in describing the invention, the food article receiving container will be referred to throughout the specification and some of the claims as a “basket”. The hopper defines a “primary food article storage location” which may be referred to throughout the specification and claims as a “hopper food article storage location.” The accumulator defines an “secondary food article...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com