Welding state detecting and transmitting device for resistance-welding machine

a technology of transmitting device and welding state, which is applied in the direction of welding monitoring device, welding apparatus, manufacturing tools, etc., can solve the problems of troublesome physical access to the welding state transmitting device attached to the secondary side, loss of advantages of the second prior art for wirelessly transmitting data to the external device, and troublesome replacement of batteries or recharging batteries within the device, etc., to achieve the effect of reducing the burden of maintenance operations and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0033] (First Embodiment)

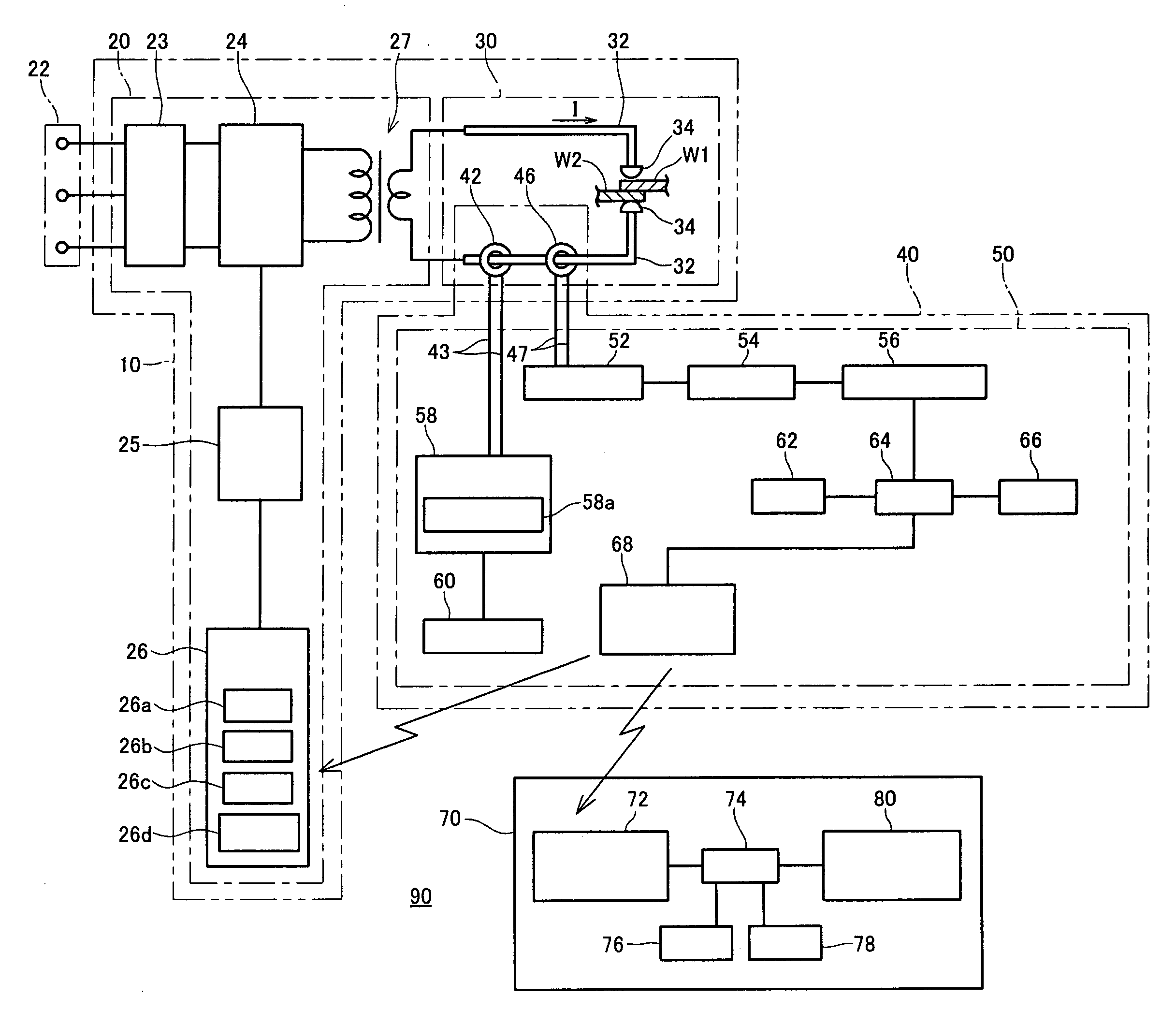

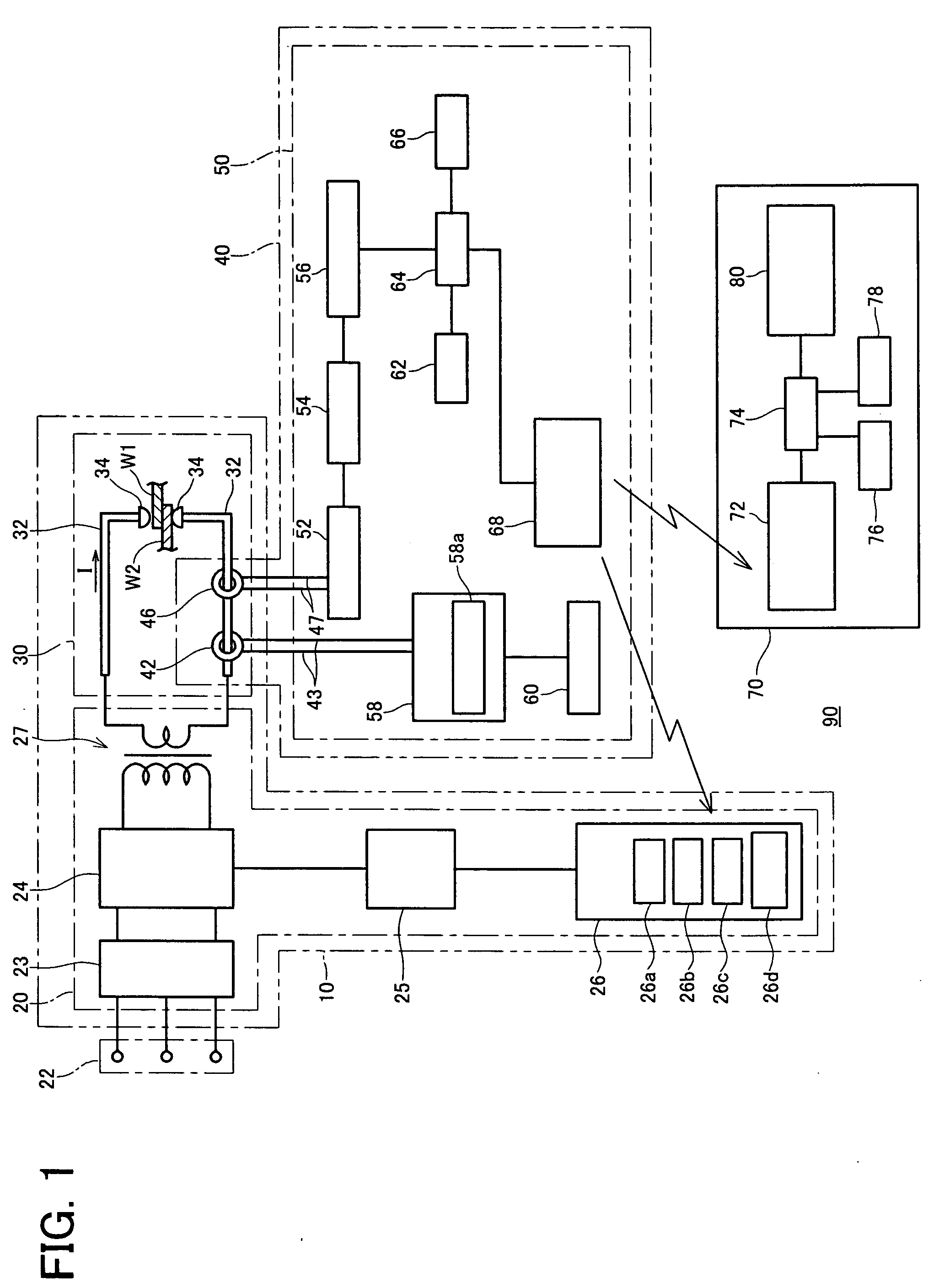

[0034]FIG. 1 is an explanatory view showing a welding state detecting and transmitting device 40 of a first embodiment, and a welding state detecting system 90. The system 90 is provided with a resistance-welding machine 10, the welding state detecting and transmitting device 40, and an external device 70 for receiving data from the device 40, storing the received data, processing the received data, storing the processed data, and outputting the received and the processed data.

[0035] The resistance-welding machine 10 is provided with a circuit unit 20 and a welding gun unit 30. The circuit unit 20 is provided with a commutating circuit 23, an inverter circuit 24, and a transformer 27, these being connected in sequence. The commutating circuit 23 is connected with a commercial three-phase alternating current source 22. The circuit unit 20 is further provided with a driving circuit 25 connected with the inverter circuit 24, and a welding state controlling dev...

second embodiment

[0062] (Second Embodiment)

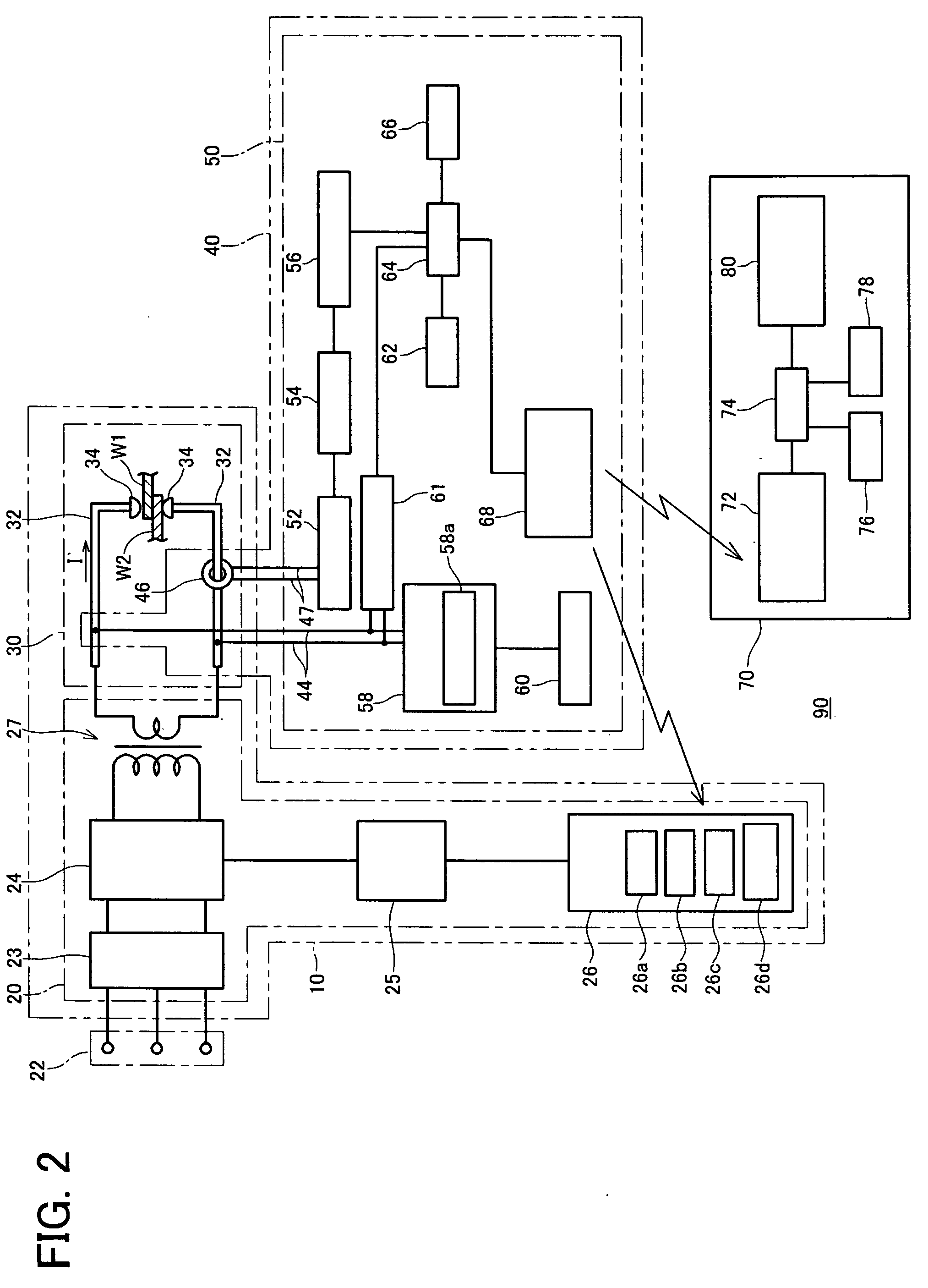

[0063]FIG. 2 is an explanatory view showing a welding state detecting and transmitting device 40 and a welding state detecting system 90 of a second embodiment.

[0064] In this system, a pair of cables 44 is connected with a charging circuit 58 of the device 40. Each of the pair of cables 44 is connected with one of the pair of secondary side conductors 32. Further, the pair of cables 44 bifurcates and is connected with an A / D conversion circuit 61. The A / D conversion circuit 61 is connected with a CPU 64. By this means, voltage data originating from the pair of secondary side conductors 32, 32 can be detected, processed, and analyzed, etc. These points are the main differences of the second embodiment from the first embodiment.

[0065] In addition to the functions described above, the welding state detecting and transmitting device 40 of the first or second embodiments also has the following effects.

[0066] (1) By using the charging toroidal coil 42 (first e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric power | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com