Container with easily removable membrane lid

a container and lid technology, applied in the field of containers, can solve the problems of inaccurate control, consumer difficulty in peeling off the lid, etc., and achieve the effect of relatively easy peeling of the lid from the container and low bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

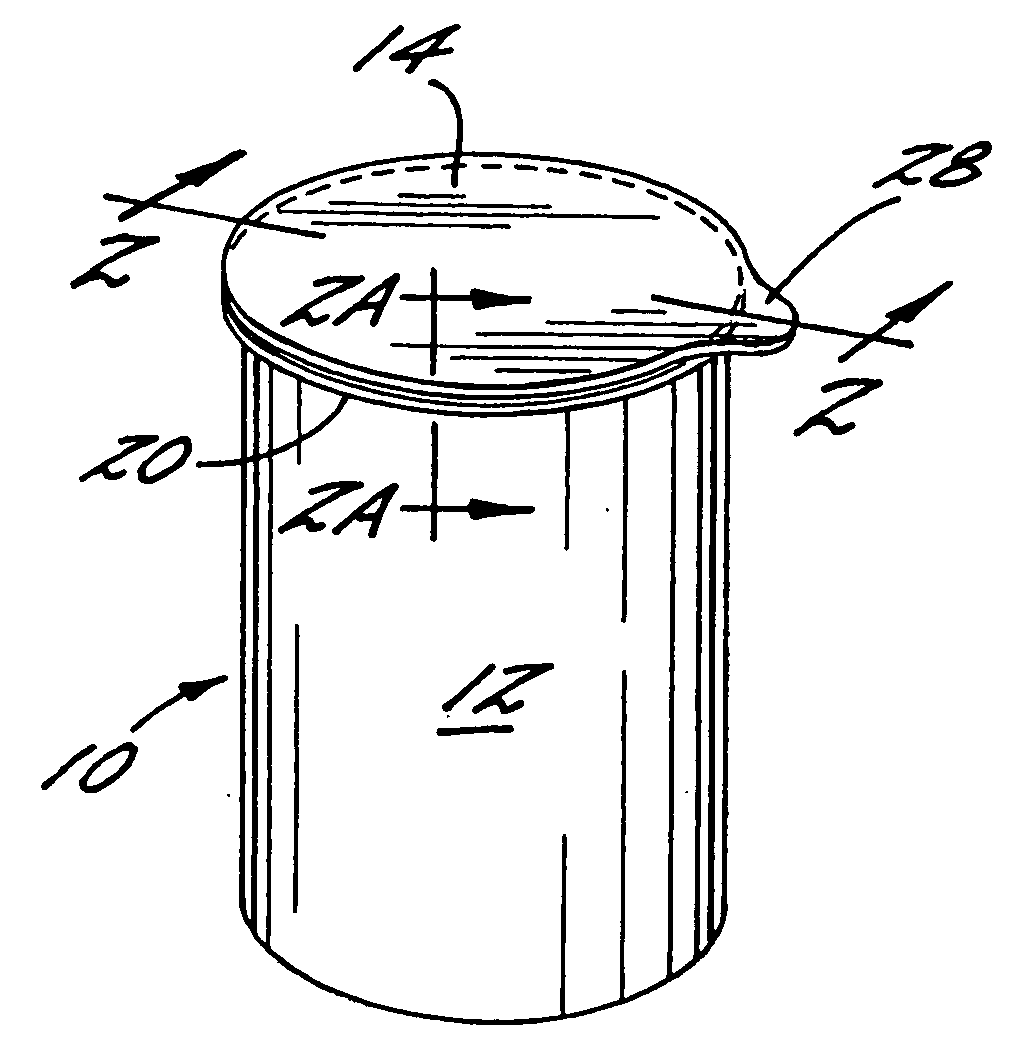

[0025] A container 10 in accordance with the invention is shown in FIGS. 1, 2, 2A, and 3. The container 10 includes a container body 12 and a flexible membrane lid 14. The container body 12 can be formed of various materials and in various configurations, and by various processes. Generally, the container body includes a bottom wall 16, a tubular sidewall 18 having a lower end joined to the outer periphery of the bottom wall, and a flange 20 joined to an upper end of the sidewall. The flange encircles a top opening of the container body. In the instant embodiment, the flange 20 extends radially outwardly from the sidewall. The flange defines a substantially planar upper surface to which the lid 14 is attached to seal closed the top opening of the container body.

[0026] With reference to FIG. 2A in particular, the lid 14 is attached to the flange 20 by a sealant 22 disposed on the upper surface of the flange 20 and a compatible sealant 24 disposed on the lower surface of the lid 14. I...

second embodiment

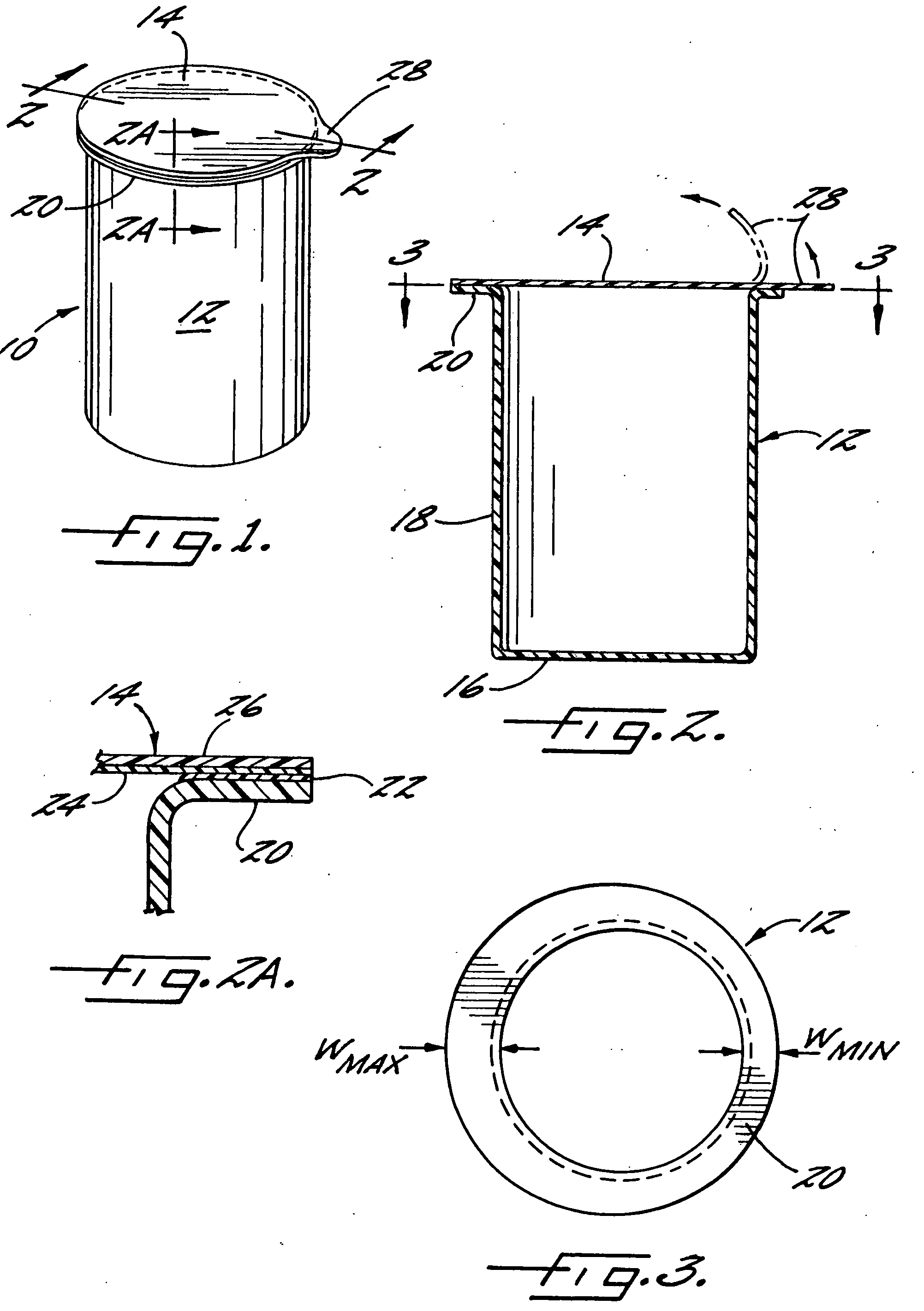

[0033]FIG. 4 illustrates the invention. The container 10′ in accordance with this embodiment is generally similar to the previously described container, except the flange 20′ projects radially inwardly from the container sidewall 18 instead of radially outwardly.

third embodiment

[0034] The objective of providing a seal that has at least one relatively narrow portion can be accomplished in ways other than providing a variable-width flange. For instance, FIG. 5 shows the invention having a container body 112 that includes a flange 120 of uniform width, but wherein the sealant 122 is applied to the flange in a variable-width pattern. In particular, the sealant covers substantially the full width of the flange over most of the flange's circumference, but over a minor circumferential portion of the flange the sealant covers only part of the width of the flange. The sealant can be applied to the flange in any suitable fashion, such as by printing with a rotogravure cylinder or the like. When a lid (not shown) having a compatible sealant is sealed to the flange 120, the resulting seal has a narrow portion at which peeling of the lid can be initiated.

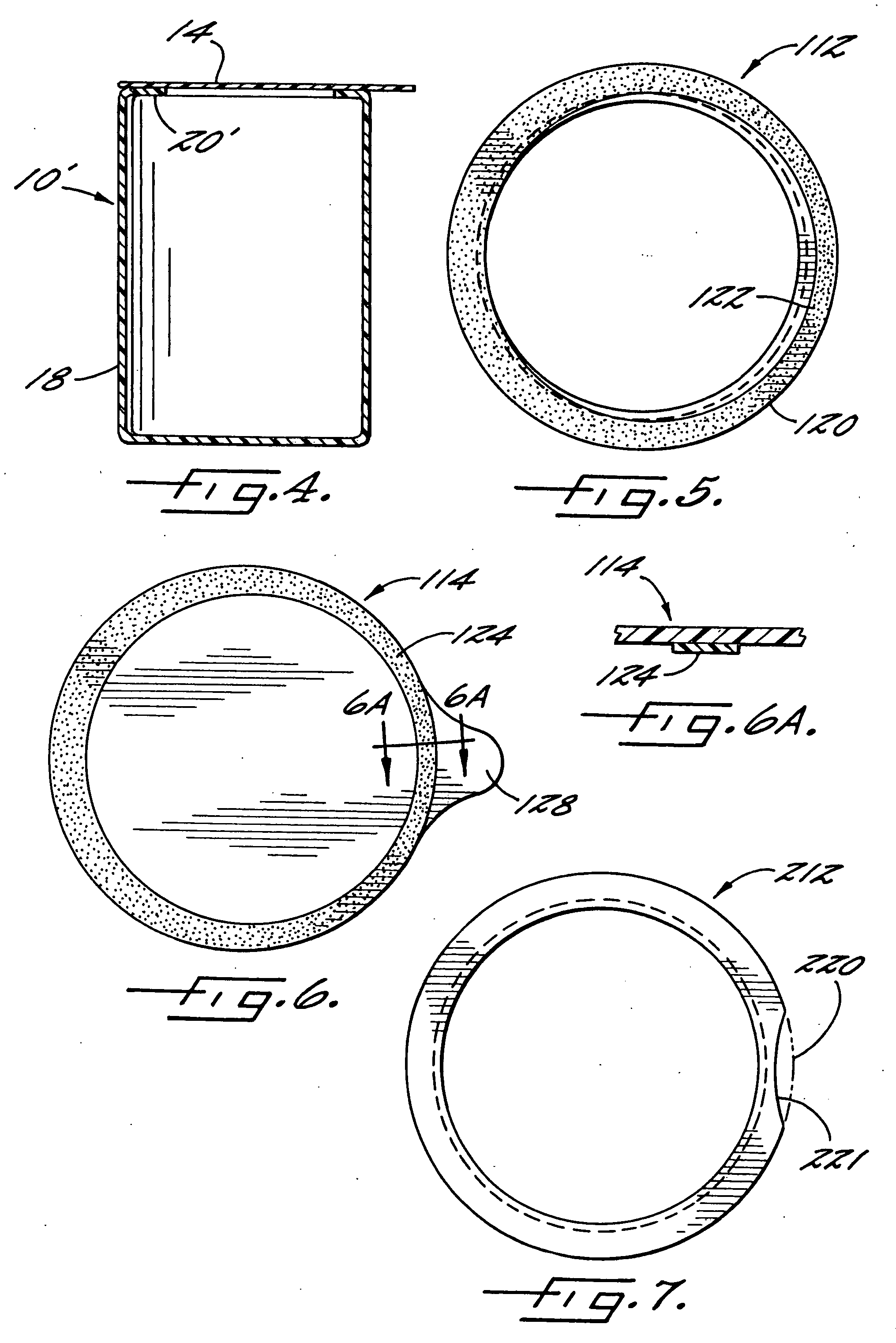

[0035]FIG. 6 illustrates that the variable-width sealant pattern can be applied to the lid instead of, or in additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com