Method and apparatus for variable frequency controlled compressor and fan

a variable frequency control and compressor technology, applied in lighting and heating apparatus, positive displacement liquid engines, separation processes, etc., can solve the problems of compressor operating at a higher than necessary capacity, consuming a larger amount of electrical power than necessary, and unable to meet the demand on the air system. 100% of the designed capacity,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

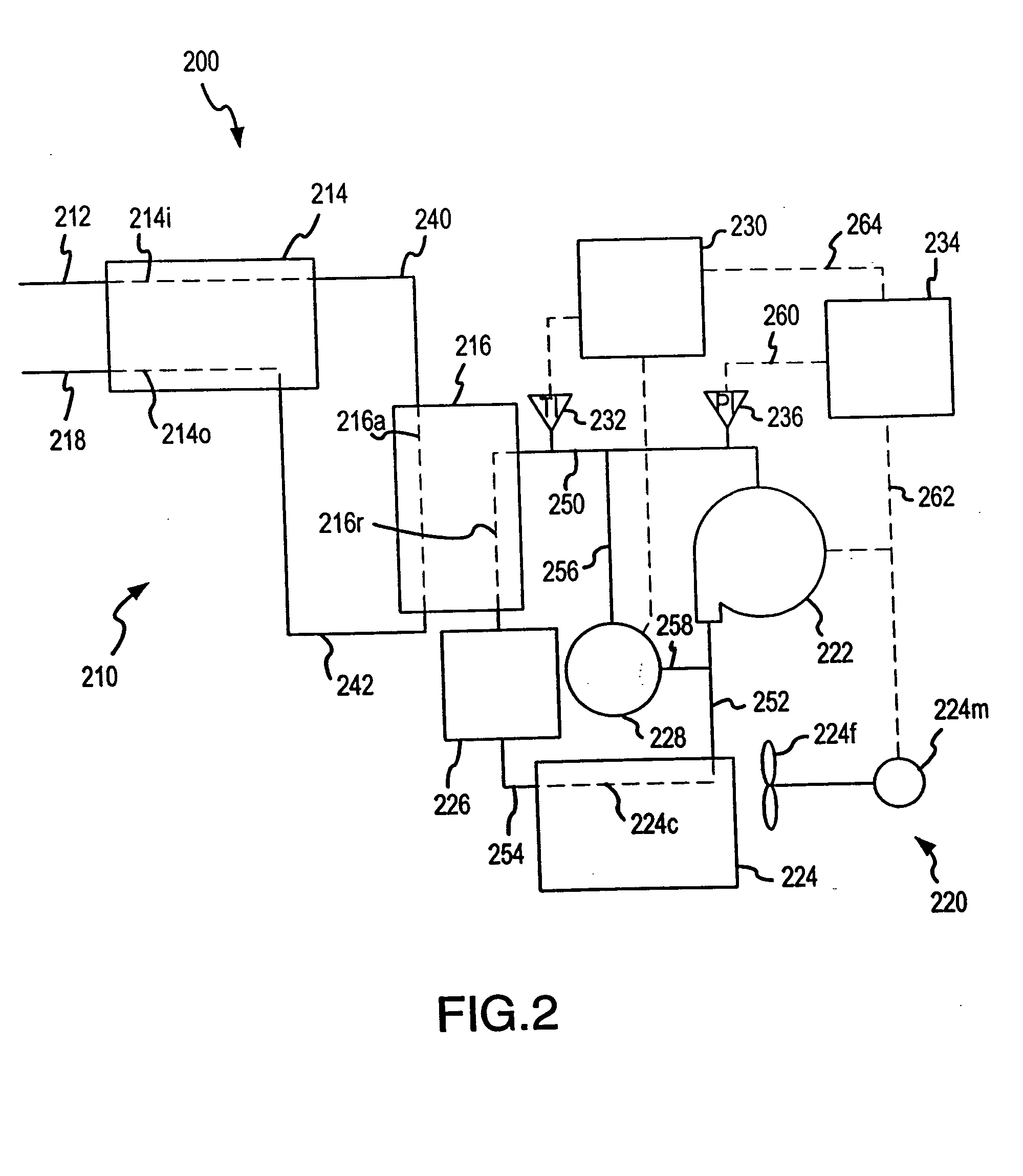

[0024] Some embodiments of the present invention are shown in FIGS. 2 through 9. FIG. 2 shows a refrigerated air dryer 200 in accordance with one possible embodiment of the present invention. Air dryer 200 includes both an air heat exchanger circuit 210 and a refrigerant heat exchanger circuit 220. Air heat exchanger circuit 210 includes an inlet 212, an air-to-air heat exchanger 214, a air-to-refrigerant heat exchanger or evaporator 216, and an air outlet 218. Air heat exchanger circuit 210 also has a conventional separator and automatic drain system (not shown) that is known in the art.

[0025] Air heat exchanger circuit 210 operates by receiving an air or gas stream at inlet 212. The air or gas stream travels through air-to-air heat exchanger 214. The air or gas stream circulates in piping 214i along the inlet side of air-to-air heat exchanges 214 to cool. After cooling, the air or gas stream exists into piping 240. The air or gas stream travels along piping 240 and enters air sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com