Spinal bone chisels

a technology of spine bone chisels and spine implants, which is applied in the field of spine bone chisels and the field of spinal disc space preparation, can solve the problems of lack of versatility in cutting spinal material from different adjacent areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

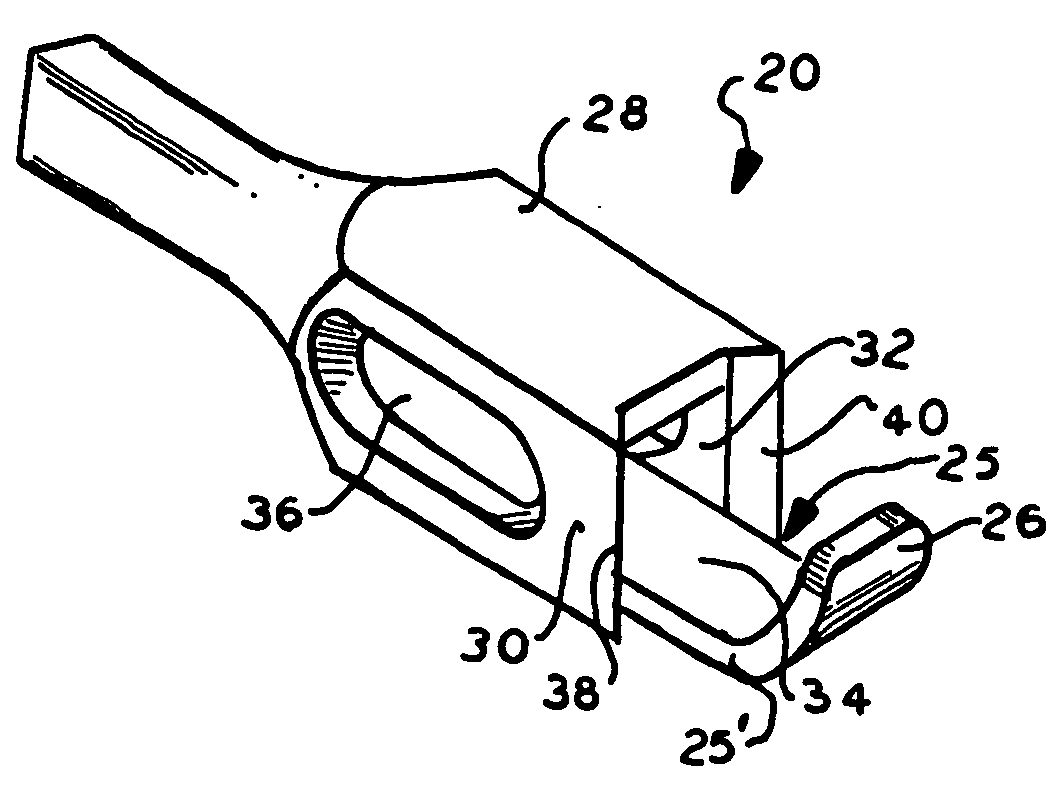

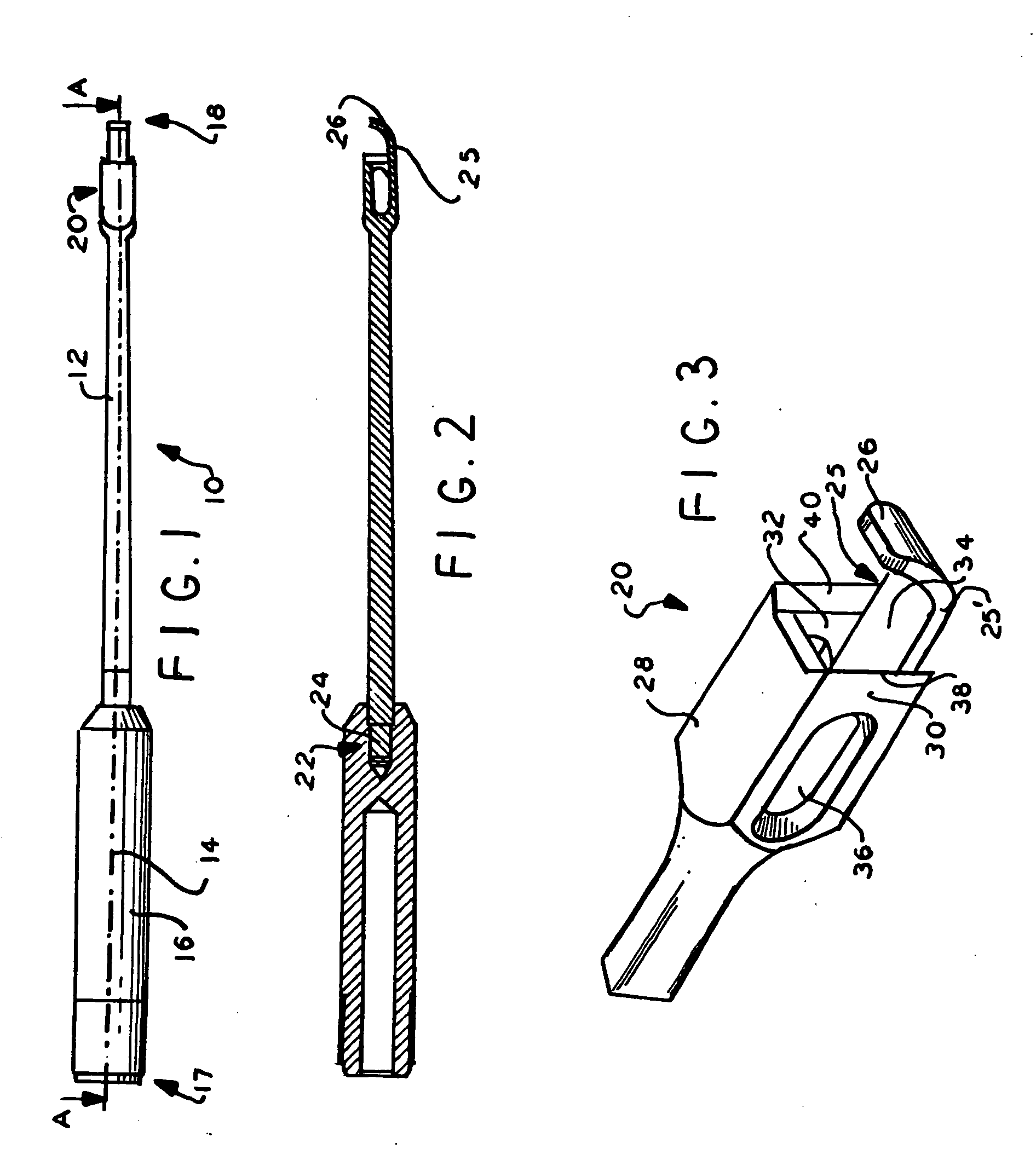

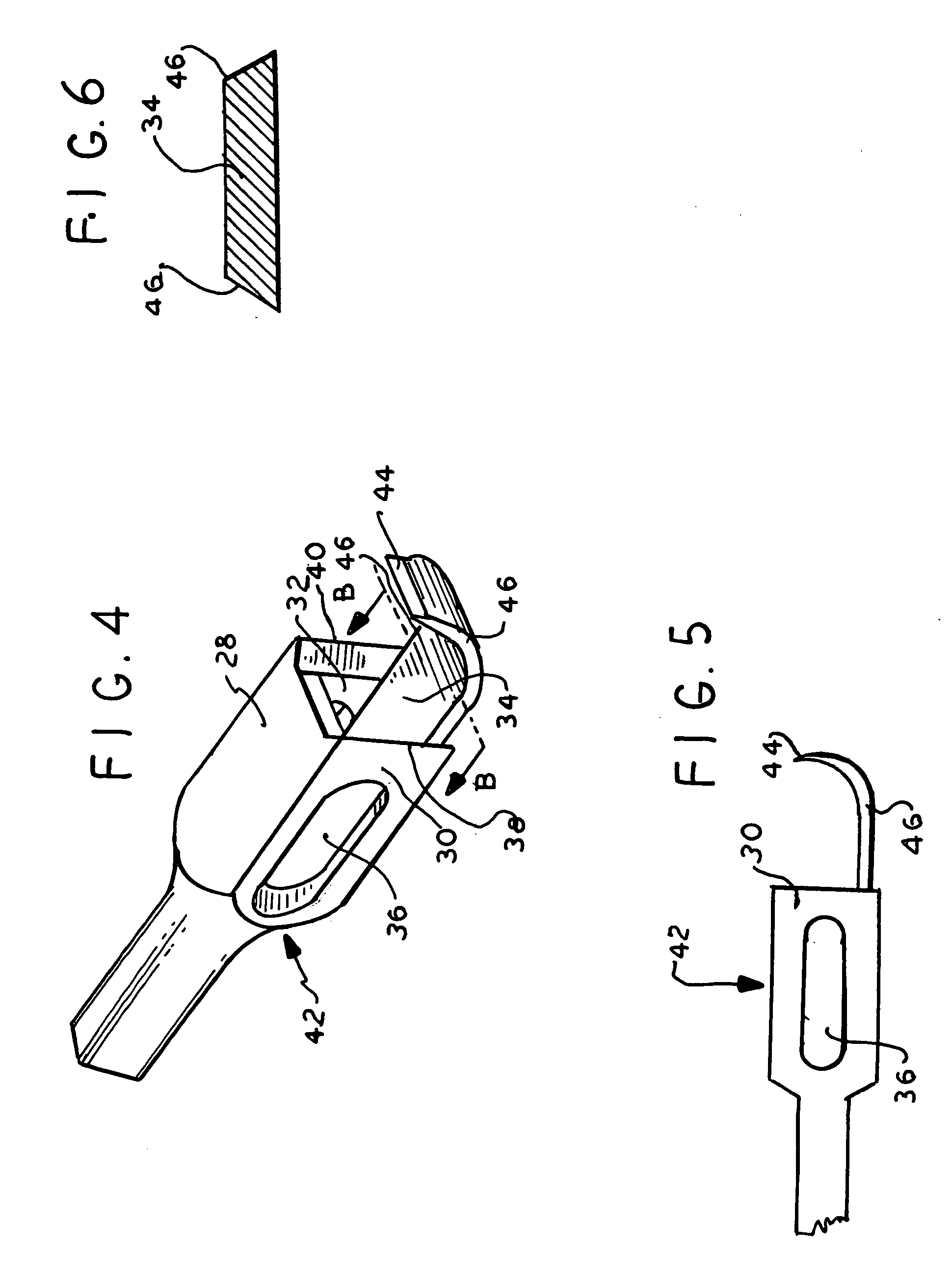

[0257] In FIG. 1, chisel instrument 10 comprises an elongated shank 12 defining a longitudinal axis 14, a handle 16 attached to the shank 12 at a proximal end 17, and a cutting head 20 attached to the shank at a distal end 18. The handle 16 (shown in FIGS. 1 and 2) may have a bore 22 in which the shank 12 is inserted and attached to the handle. The shank 12 may include a stud 24 for receiving the handle. The shank 12 may be press fit into the handle bore 22 or may be threaded to the handle at bore 22 or may be bonded to the handle such as by welding. The handle 16 is elongated and extends along the longitudinal axis 14. The handle 16 has a transverse dimension greater than that of the shank 12 to permit ease of gripping by a surgeon during use. The handle and shank may be formed of stainless steel, for example, and preferably is circular cylindrical or, in the alternative may have other cross section shapes such as square or rectangular, for example. The handle 16 may also have flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com