Heat exchanger

a heat exchanger and heat exchange technology, applied in the field of heat exchangers, can solve the problems of increasing so as to achieve the effect of increasing the heat exchange efficiency of the heat exchanger, reducing the number of assembly steps, and ensuring the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] One embodiment of the present invention is explained below with reference to the attached drawings.

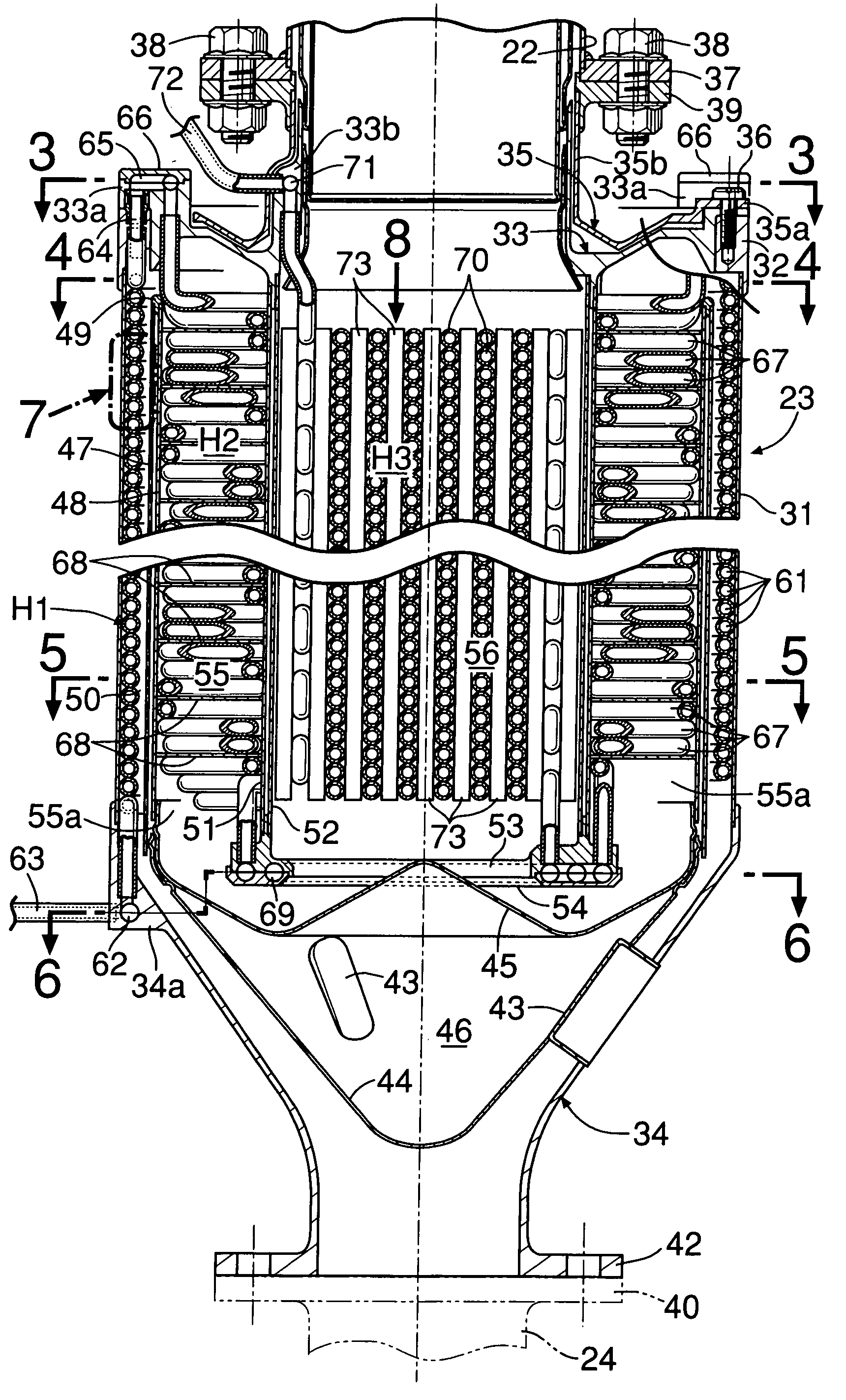

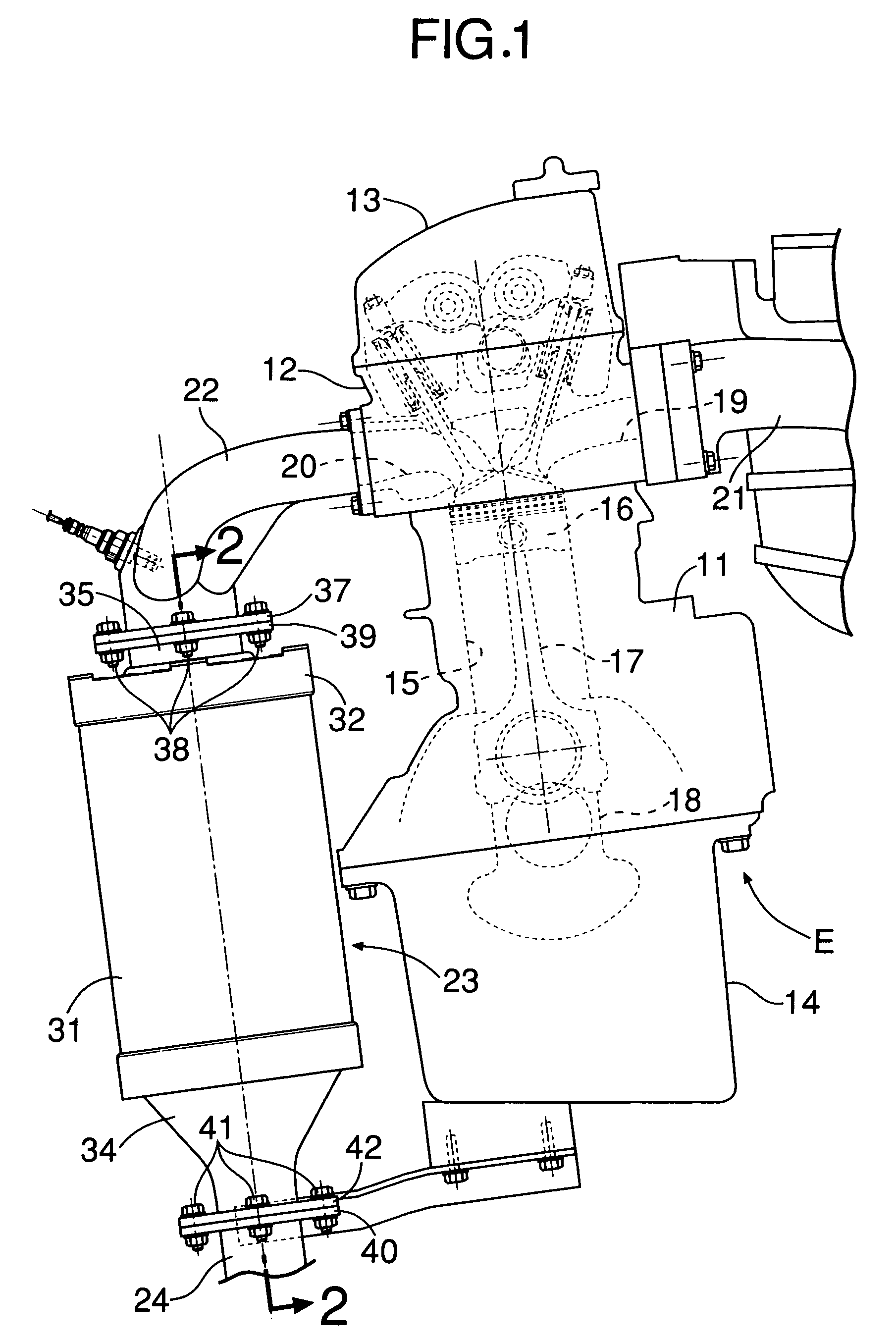

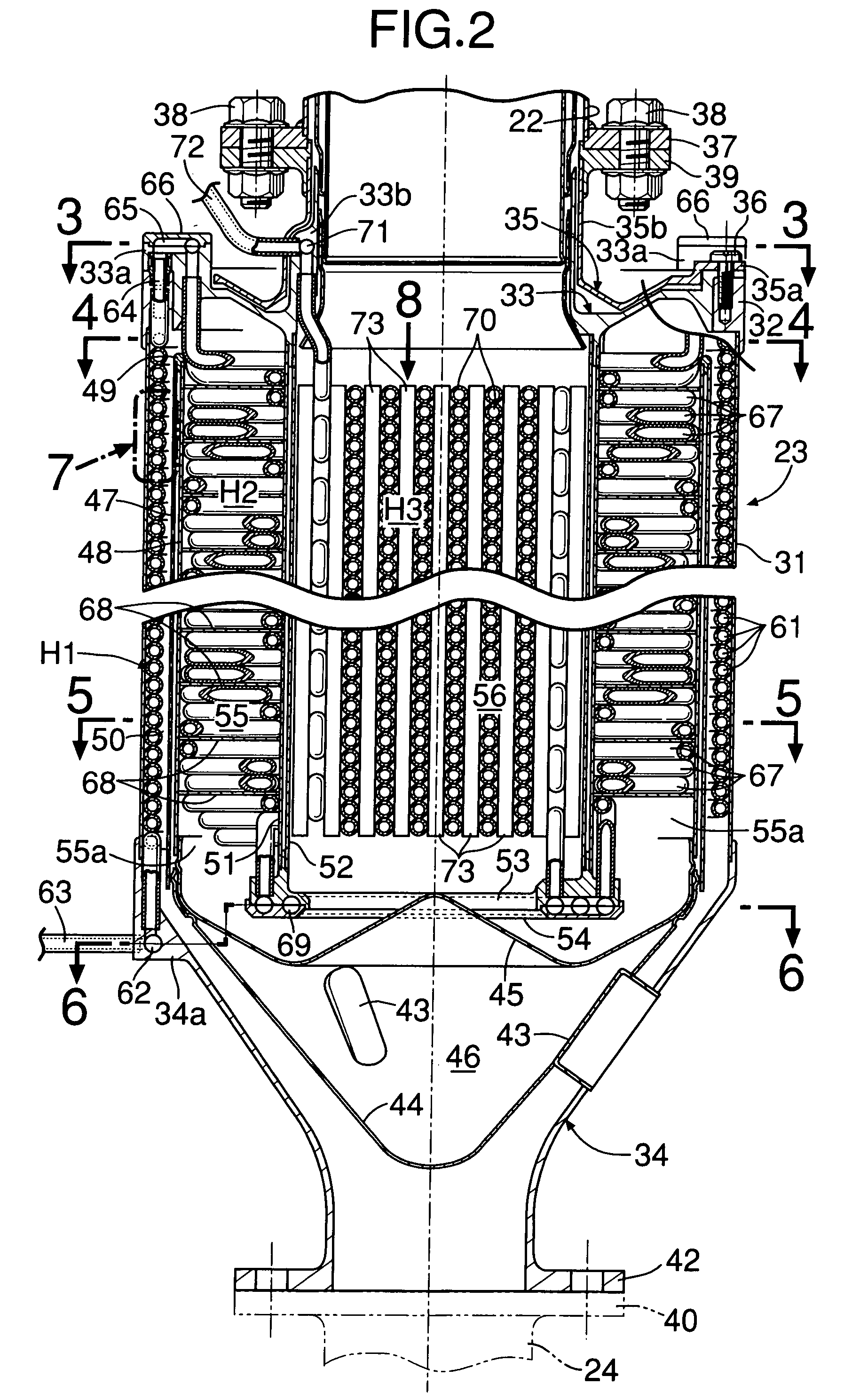

[0047] As shown in FIG. 1, an in-line multicylinder internal combustion engine E includes a cylinder head 12 and a head cover 13 joined to an upper face of a cylinder block 11, and an oil pan 14 joined to a lower face of the cylinder block 11. Pistons 16 slidably fitted in cylinder bores 15 provided in the cylinder block 11 are connected to a crankshaft 18 via connecting rods 17. An intake manifold 21 and an exhaust manifold 22 are respectively connected to intake ports 19 and exhaust ports 20 formed in the cylinder head 12, and an exhaust pipe 24 is connected to the downstream side of the exhaust manifold 22 via an evaporator 23. The evaporator 23 forms a heat exchanger of the present invention, and generates high temperature, high pressure steam by heating water as a heat-absorbing medium with the heat of exhaust gas as a thermal fluid.

[0048] The structure of the evaporator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com