Vacuum switchgear

a switchgear and vacuum technology, applied in the direction of electrical apparatus construction details, conductors, casings/cabinets/drawers, etc., can solve the problem of no longer accelerating charged particles generated by dielectric breakdown, and achieve the effect of preventing damage to devices, and preventing ground faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

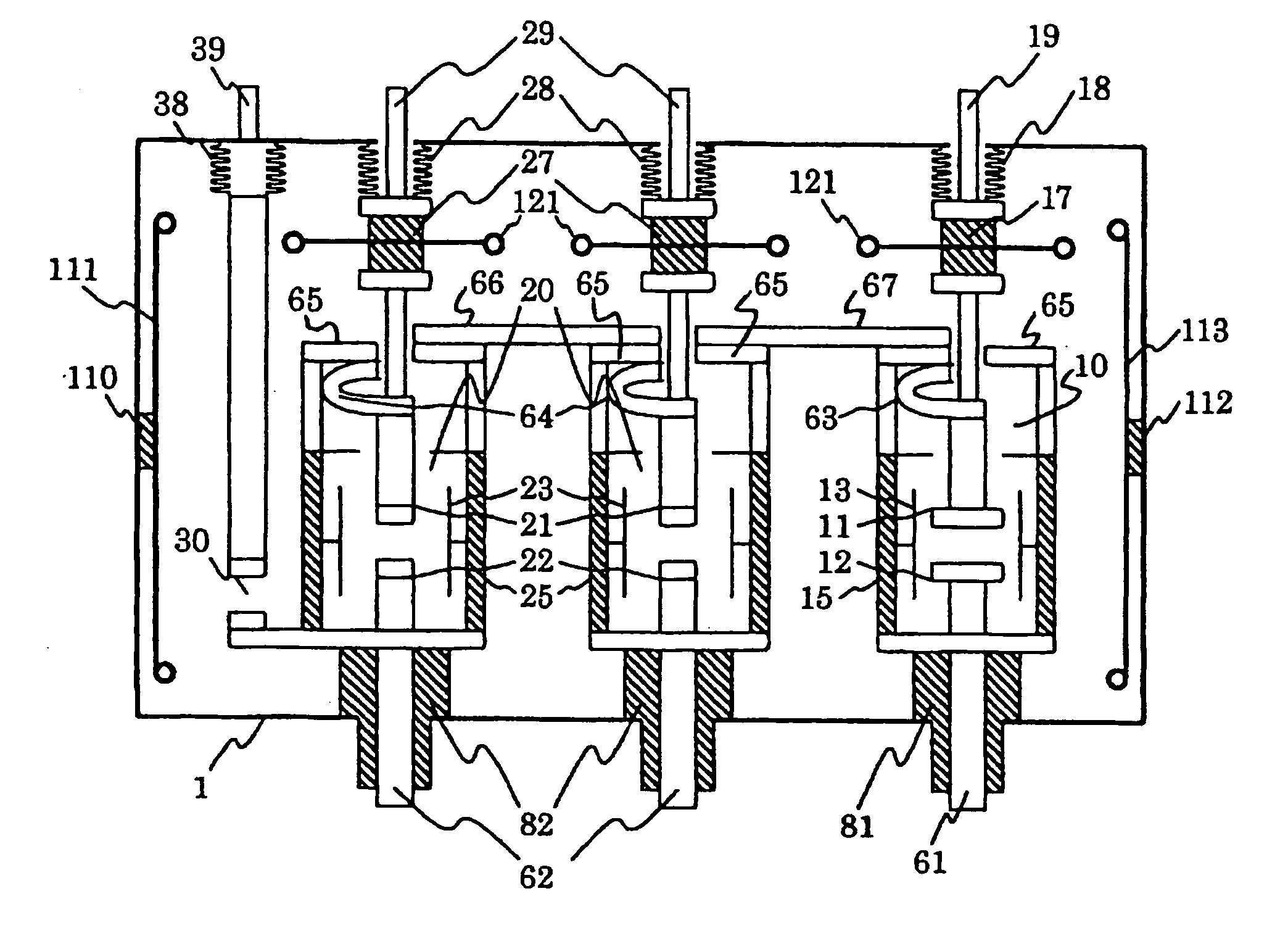

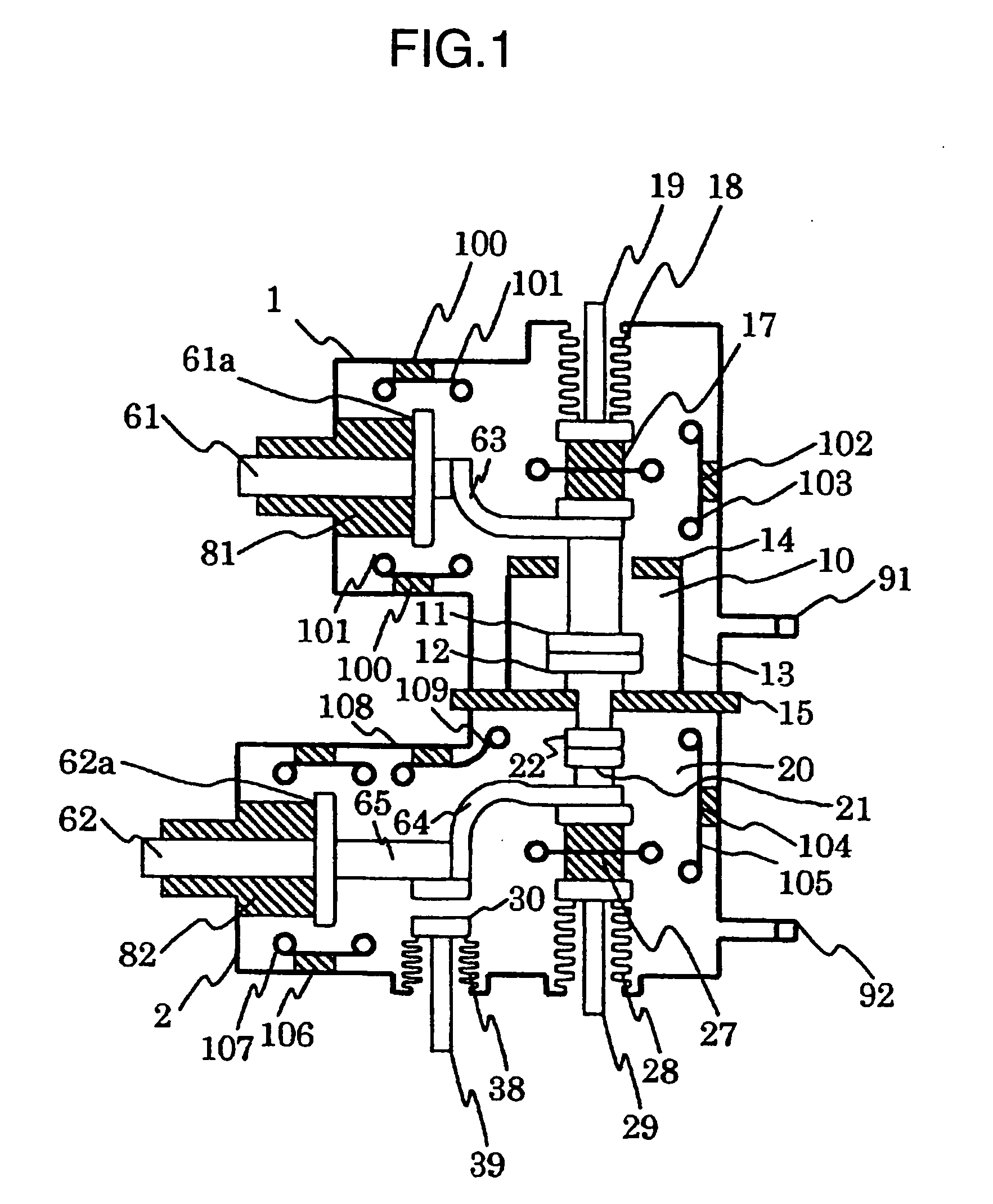

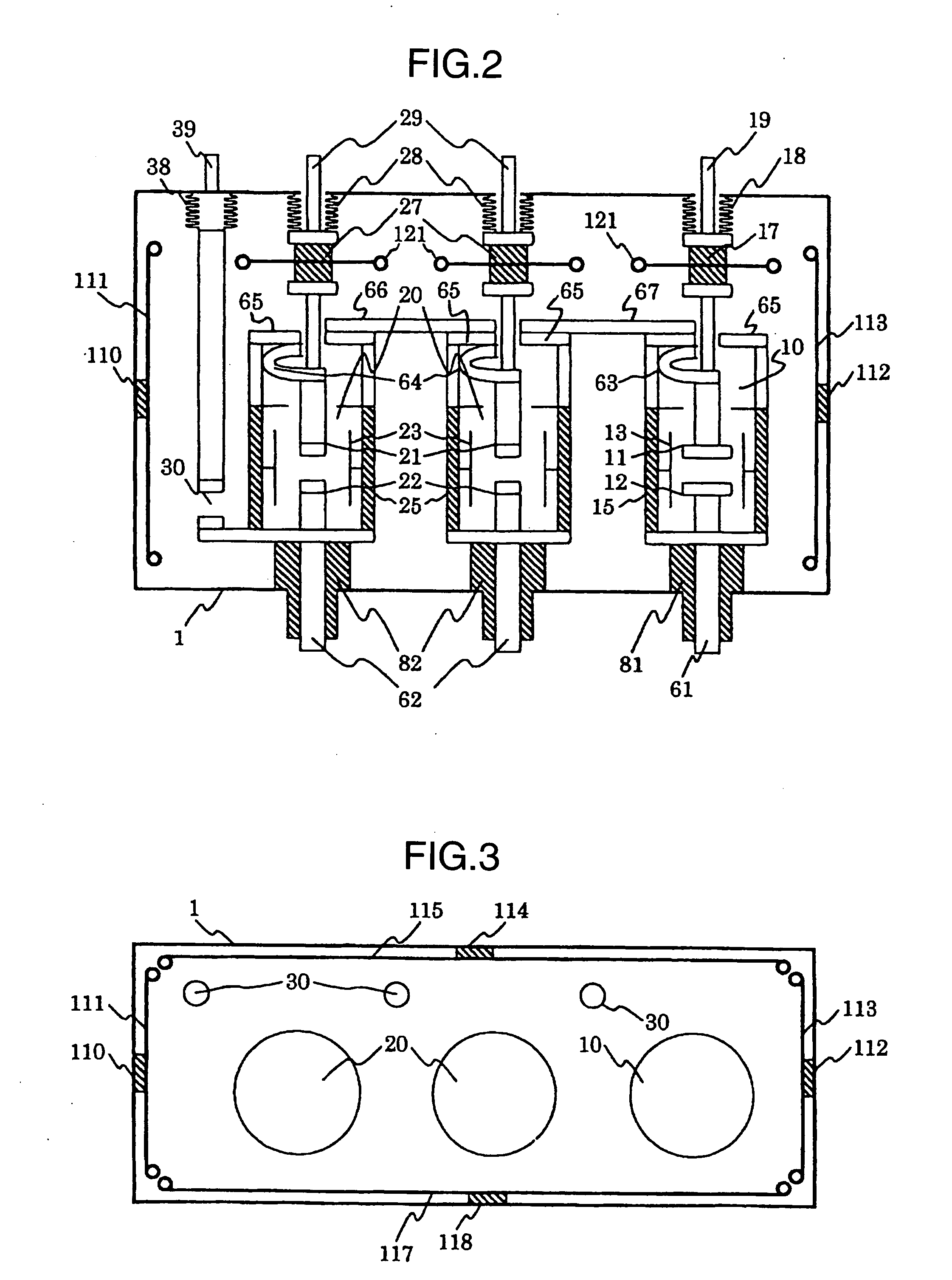

[0013] An embodiment of the invention will be now described with reference to the accompanying drawings. FIG. 1 is a vertical sectional view of a vacuum switchgear showing the embodiment of the invention. In FIG. 1, the vacuum switchgear is represented by one phase of one unit in a power receiving and distribution board comprised of a plurality of units. In this embodiment, a main circuit switching unit 10, an isolator 20, flexible conductors 63, 64, an earthing device 30 and so on are accommodated in vacuum containers 1, 2 that need to be grounded, i.e., in the vacuum containers which are grounded and formed of a metal (stainless steel). A conductor 61 and a main circuit conductor 62 are arranged to extend inside and outside the vacuum containers 1, 2.

[0014] The main circuit switching unit 10 has a movable electrode 11 and a stationary electrode 12 and is installed in the vacuum container 1, separated by a spacer 15 from the isolator 20. An intermediate shield 13 is arranged aroun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resistance | aaaaa | aaaaa |

| vacuum | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com