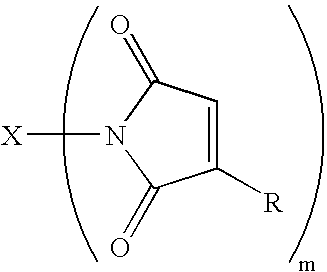

Film adhesives containing maleimide compounds and methods for use thereof

a technology of maleimide compounds and film adhesives, applied in the field of film adhesive compositions, can solve the problems of unreliable component performance, multiple challenges in the production of reliable electronic components containing stacked die packages,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0101] An adhesive composition according to the present invention was prepared as follows. Invention Formulation 1 was prepared using the styrene-butadiene block copolymer KRATON™ D-1102 as the thermoplastic elastomeric component. Octadecylmaleimide and X-BMI (X-BMI is the 1,20-bismaleimido derivative of 10,11-dioctyl-eicosane) were employed as macromonomers. The maleimides used in the following invention formulations were prepared according to the procedure set forth in U.S. Pat. No. 5,973,166, the entire contents of which are incorporated by reference herein.

Invention Formulation 11.Octadecylmaleimide 1.0 g2.KRATON ™ D-1102 2.5 g3.X-BMI 1.5 g4.Ricon 1301 0.2 g5.Silane coupling agent2 0.2 g6.Dicumyl peroxide0.05 g7.Xylene 5.0 g8.TEFLON ™ filler 6.9 g

1Polybutadiene 20% grafted with maleic anhydride (Sartomer)

2Proprietary silane-containing coupling agent.

[0102] Preparation of Formulation 1 began by dissolving octadecylmaleimide in xylene. KRATON was added to this solution and all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com