Mult- purpose end-mill

a technology of end-mill and slot, which is applied in the direction of shaping cutter, manufacturing tools, transportation and packaging, etc., can solve the problems of minor accuracy loss, time-consuming, and general unsuitability of end-mill configured for rough machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

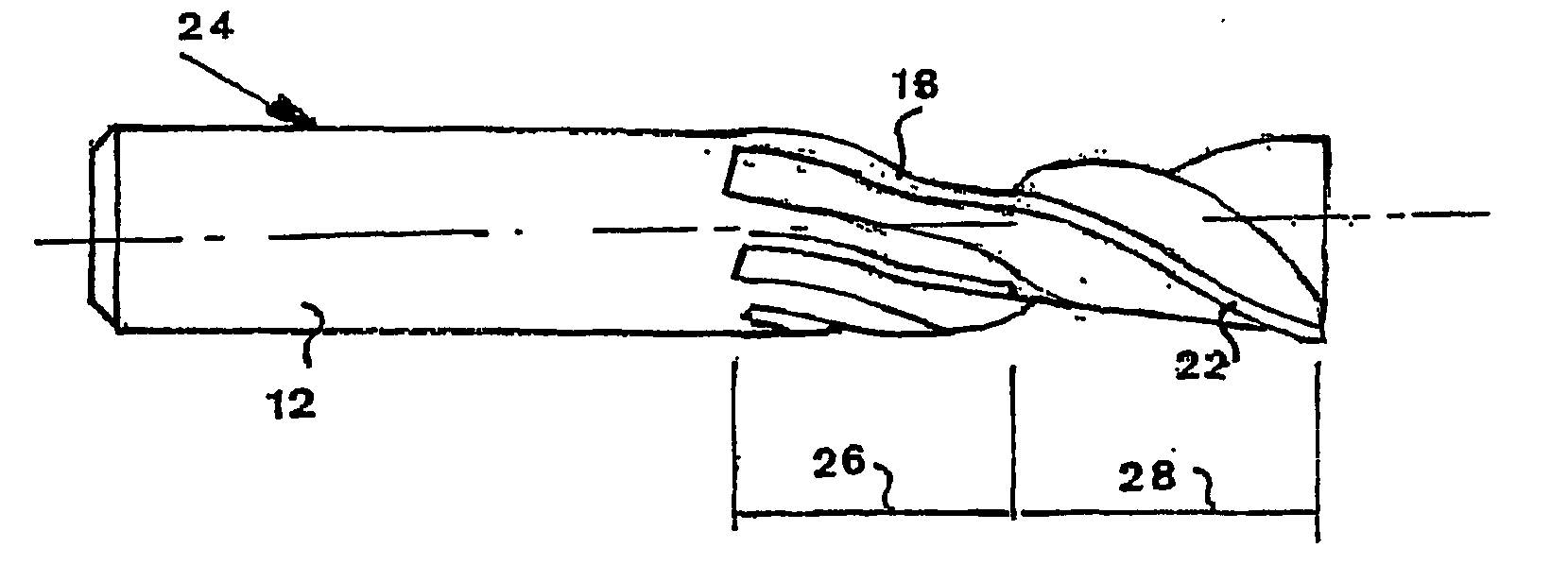

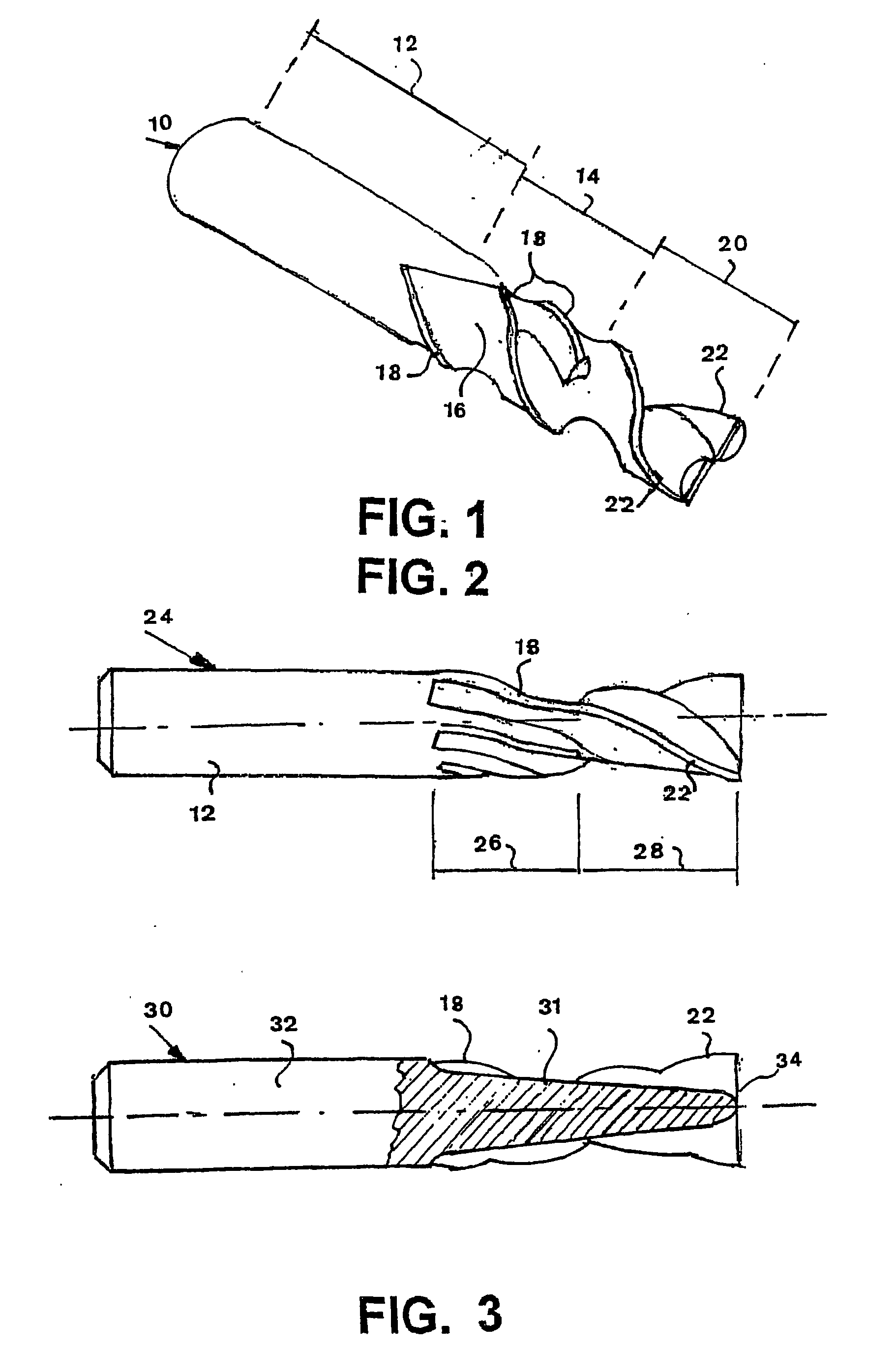

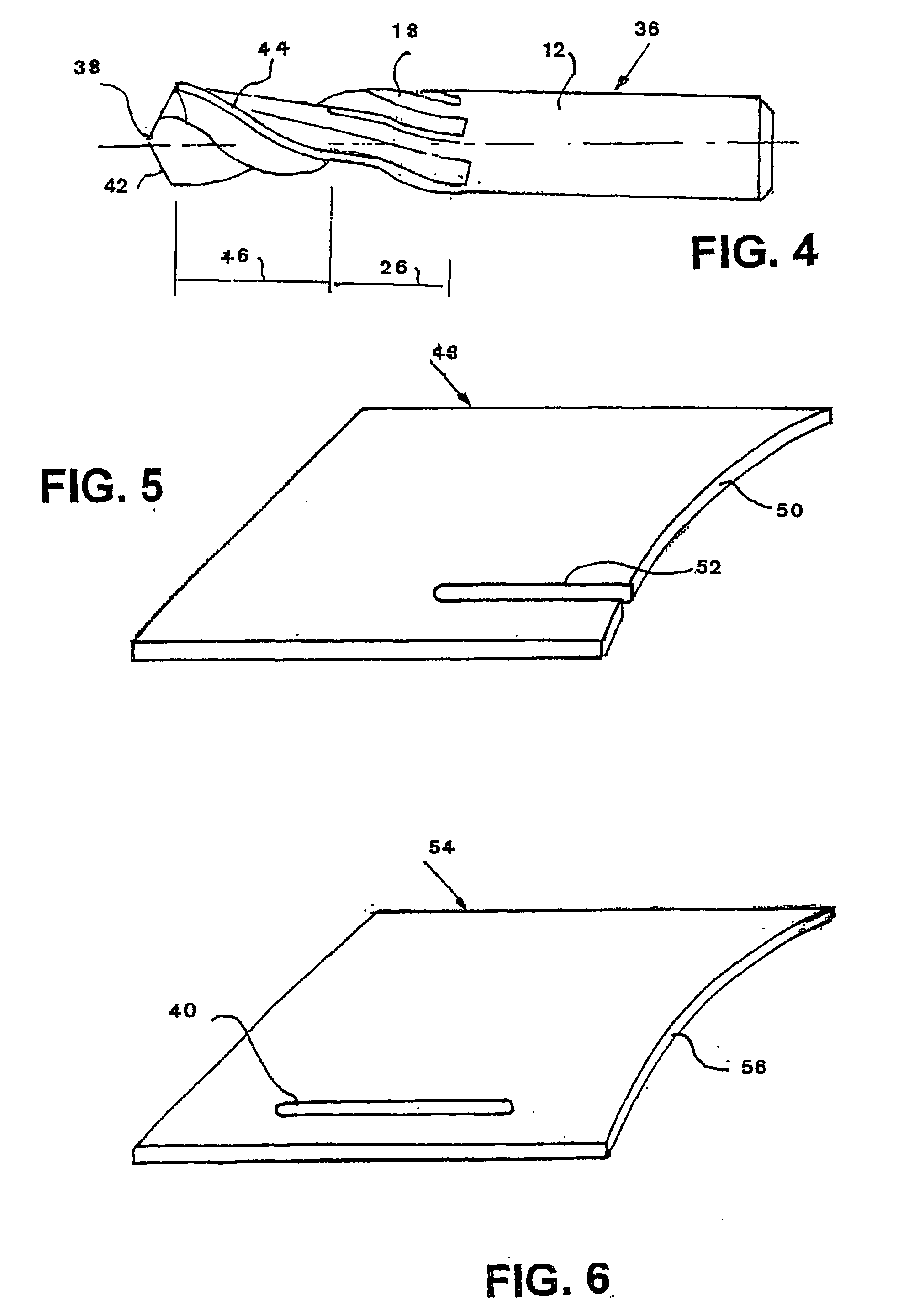

[0028] There is seen in FIG. 1 a multi-purpose end-mill 10 particularly useful for open contour machining, for example producing a workpiece of the type seen in FIG. 5. The end mill 10 is suitable for both rough machining and finish machining.

[0029] A cylindrical shank portion 12 is arranged to be gripped in a machine tool (not shown), such as a router or a milling machine, and in some types of work even a lathe or drilling machine.

[0030] The shank portion 12 is connected to a first cutting portion 14 comprising a core 16 supporting a plurality of spaced-apart cutting teeth 18 for a first type of machining.

[0031] The first cutting portion 14 is connected to a second cutting portion 20 provided with a plurality of spaced-apart cutting teeth 22 for a second type of machining.

[0032] Advantageously from considerations of core support diameter, the first type of machining is finishing, and the second type of machining is roughing. This is the arrangement in the shown embodiment. Howe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com