Reverse system for water-jet propulsion personal watercraft

a technology for reverse systems and water-jet propulsion, applied in water-borne vessels, marine propulsion, vessel construction, etc., can solve the problems of high positioning precision, relatively complex structure, and expensive stopper devices, and achieve the effect of simple structure and high positioning precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

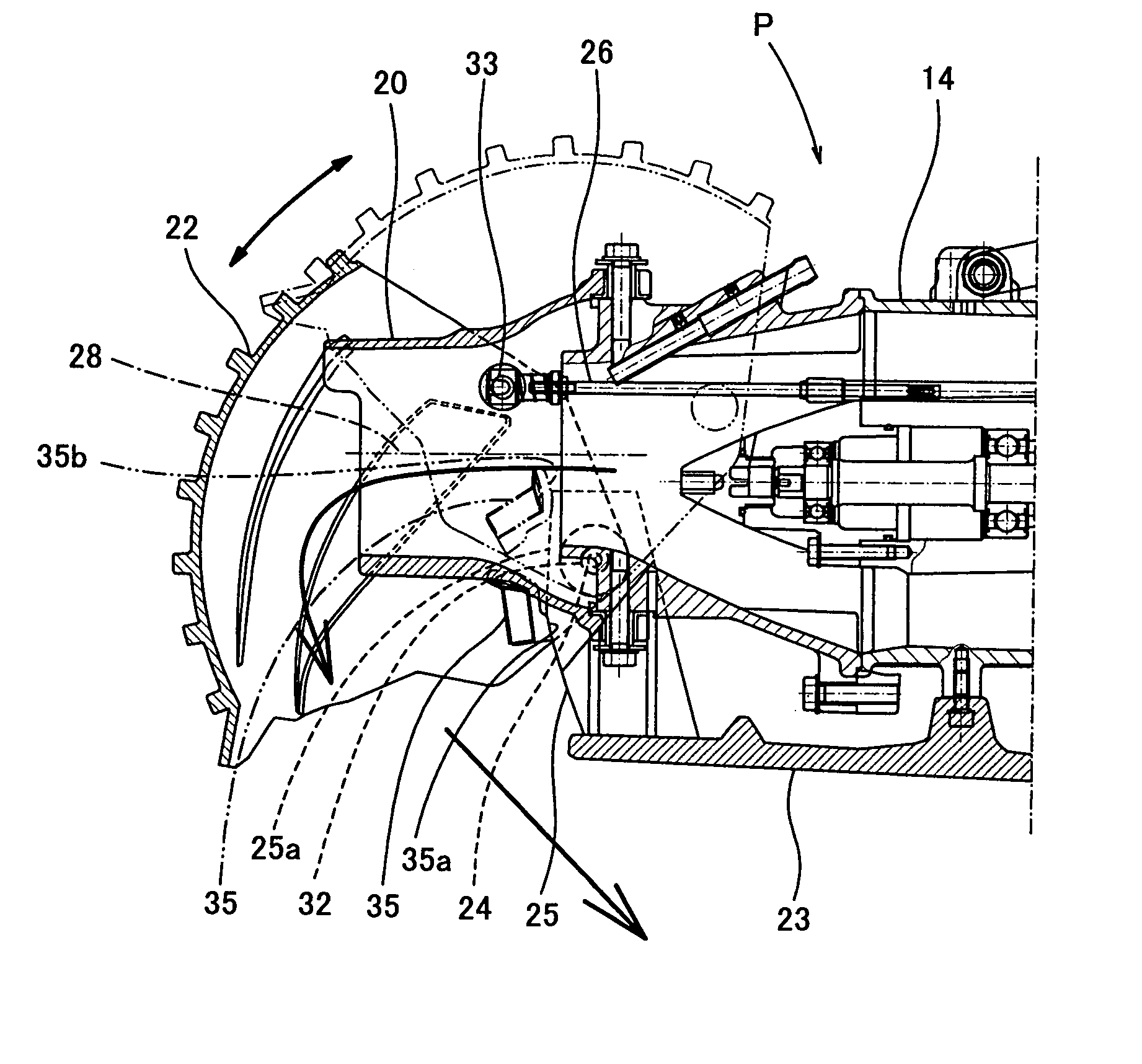

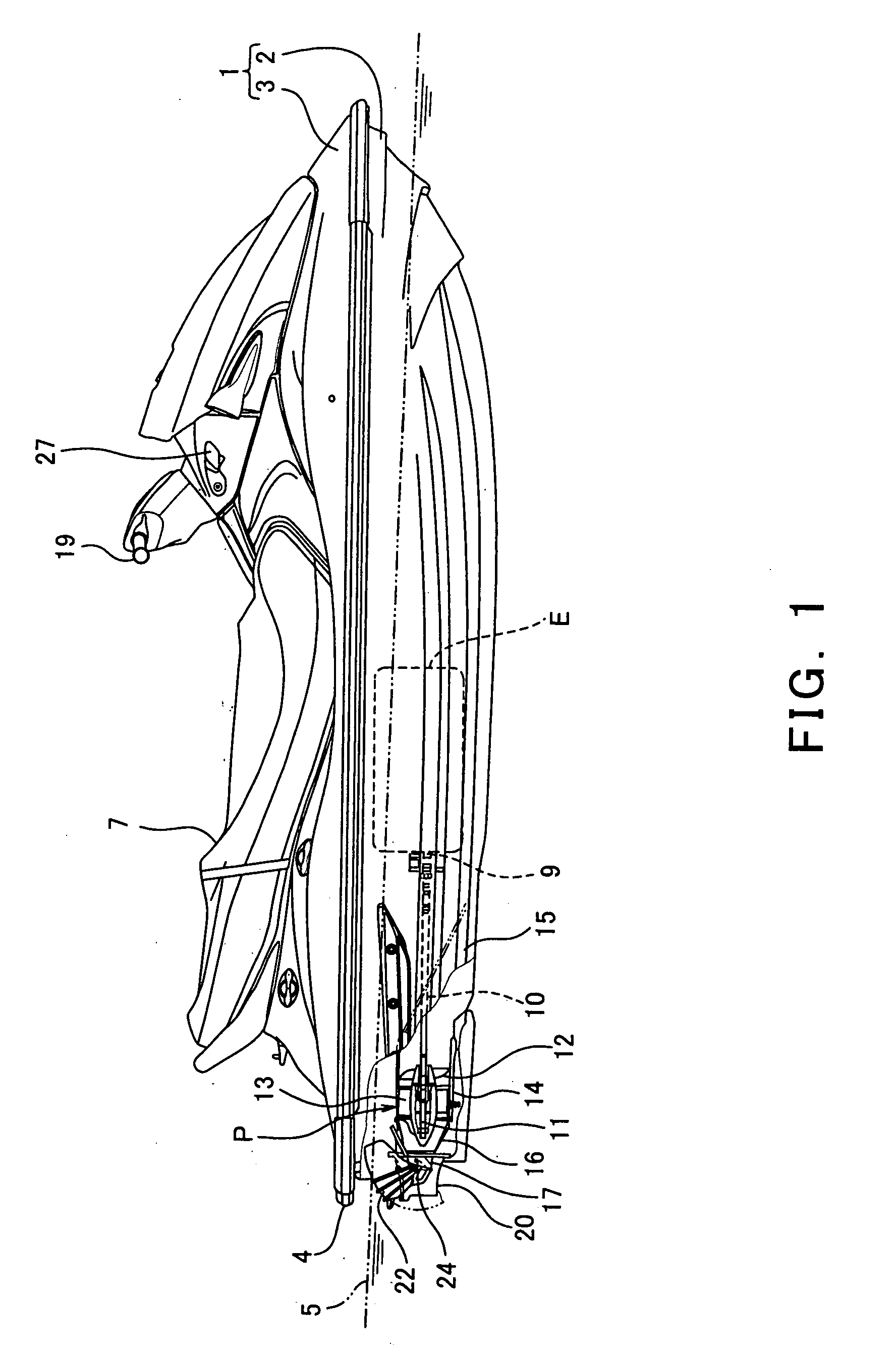

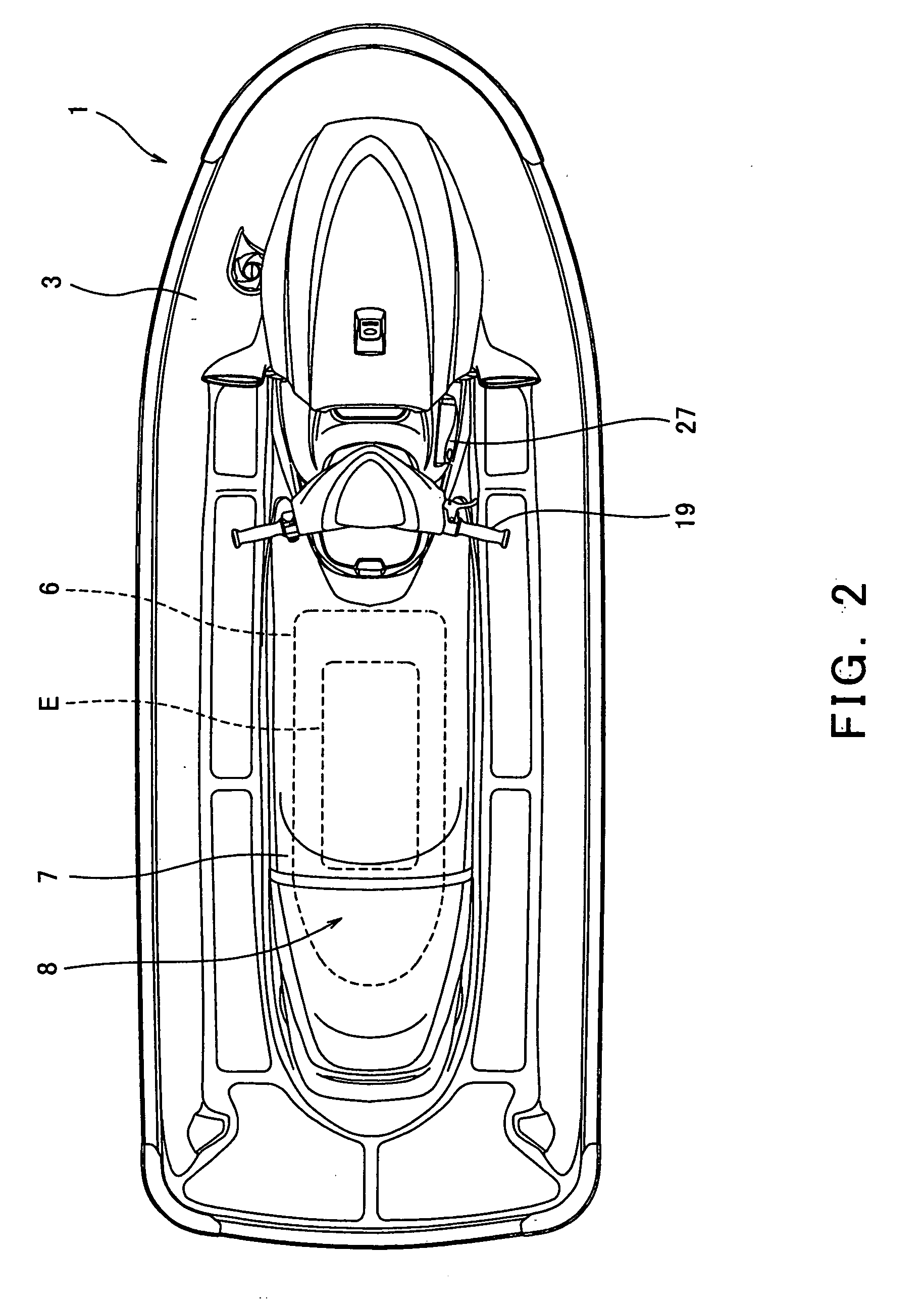

[0029] Hereinafter, a reverse system of a water-jet propulsion personal watercraft according to an embodiment of the present invention will be described with reference to drawings. The personal watercraft in FIG. 1 is a straddle-type personal watercraft equipped with a straddle-type seat 7 configured to be straddled by a rider. A body 1 of the watercraft is formed by a hull 2 and a deck 3 covering the hull 2 from above. A line at which the hull 2 and the deck 3 are connected over the entire perimeter thereof is called a gunnel line 4. The gunnel line 4 is located above a waterline 5 of the personal watercraft being at rest on the water. Herein, directions are described as seen from the perspective of the rider straddling the seat 7, and looking ahead over the bow of the watercraft. The term “longitudinal direction” is used to refer to an orientation extending from bow to stem of the watercraft, while the term “lateral direction” is used to refer to an orientation extending from star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com