Directional casing and liner drilling with mud motor

a mud motor and casing technology, applied in the direction of directional drilling, borehole drives, drilling machines and methods, etc., can solve the problems of drilling string stuck in the borehole, other problems are often encountered, and the process is very time-consuming and costly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

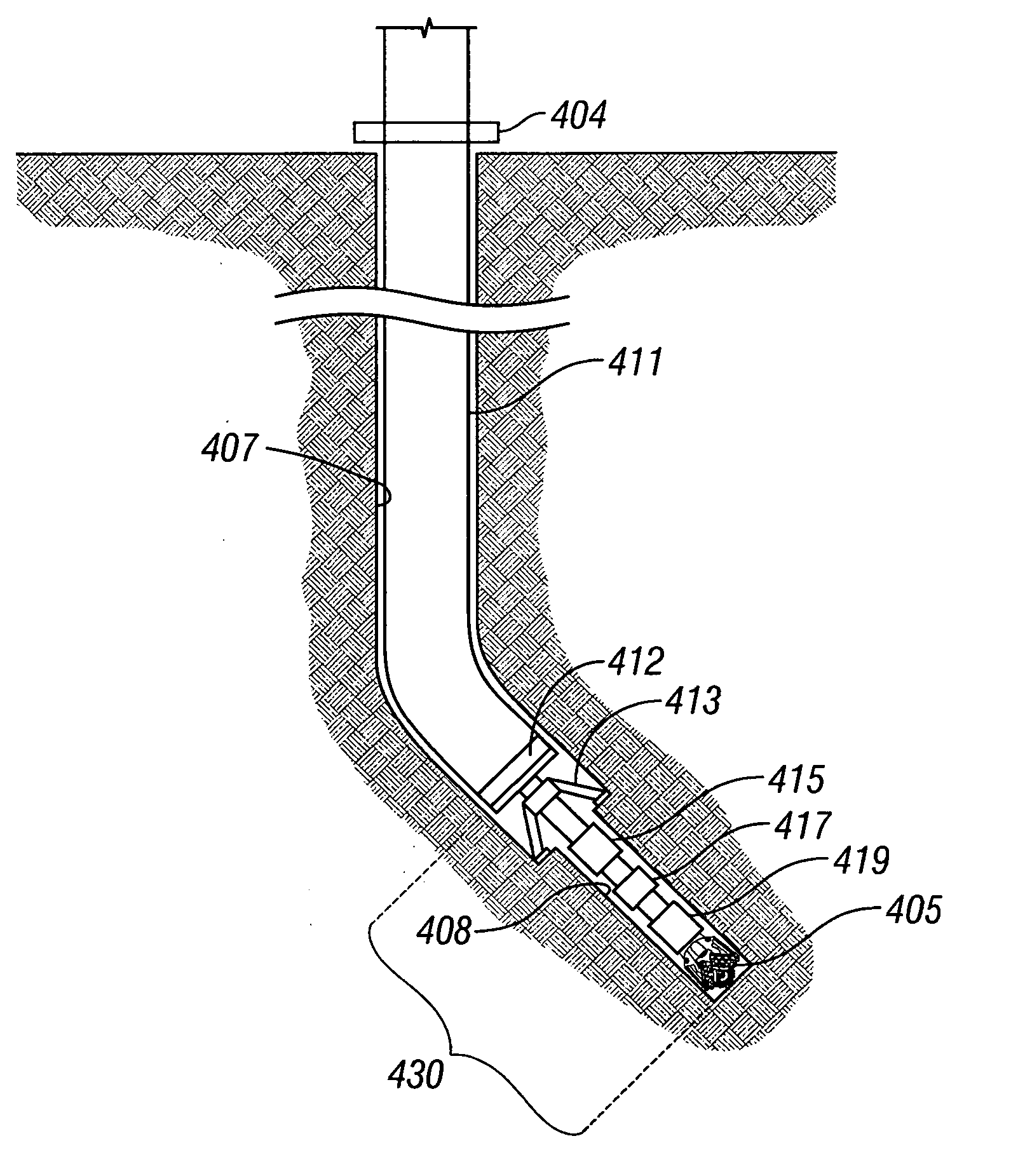

[0043] In some embodiments, the invention relates to a directional casing drilling system with a mud motor located near a rotary steerable system disposed inside the casing string. In other embodiments, the invention relates to a method of directional drilling with casing.

[0044]FIG. 4 shows a directional casing drilling system in accordance with one embodiment of the invention. A bottom hole assembly 430 (“BHA”) is positioned below a casing string 411 that is used as a drill string. It is noted that in some embodiments, some of the components of the BHA 430 may be positioned in a different order than is shown in FIG. 4 (as described below), and some components may be disposed inside the casing string 411. The exact position of each component of the BHA 430 is not intended to limit the invention.

[0045] The casing string 411 transmits rotary motion and downward force (called weight-on-bit or “WOB”) to a drill bit 405 positioned below the lower end of the casing string 411. The drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com